Flare gas recovering technique during producing polypropylene using interval liquid-phase substantial method

A production process and liquid-phase ontology technology, which is applied in the field of torch gas recovery process in the intermittent liquid-phase bulk method polypropylene production process, can solve the problems of waste of raw materials, air pollution, etc., and achieve the effect of reducing emissions and protecting the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

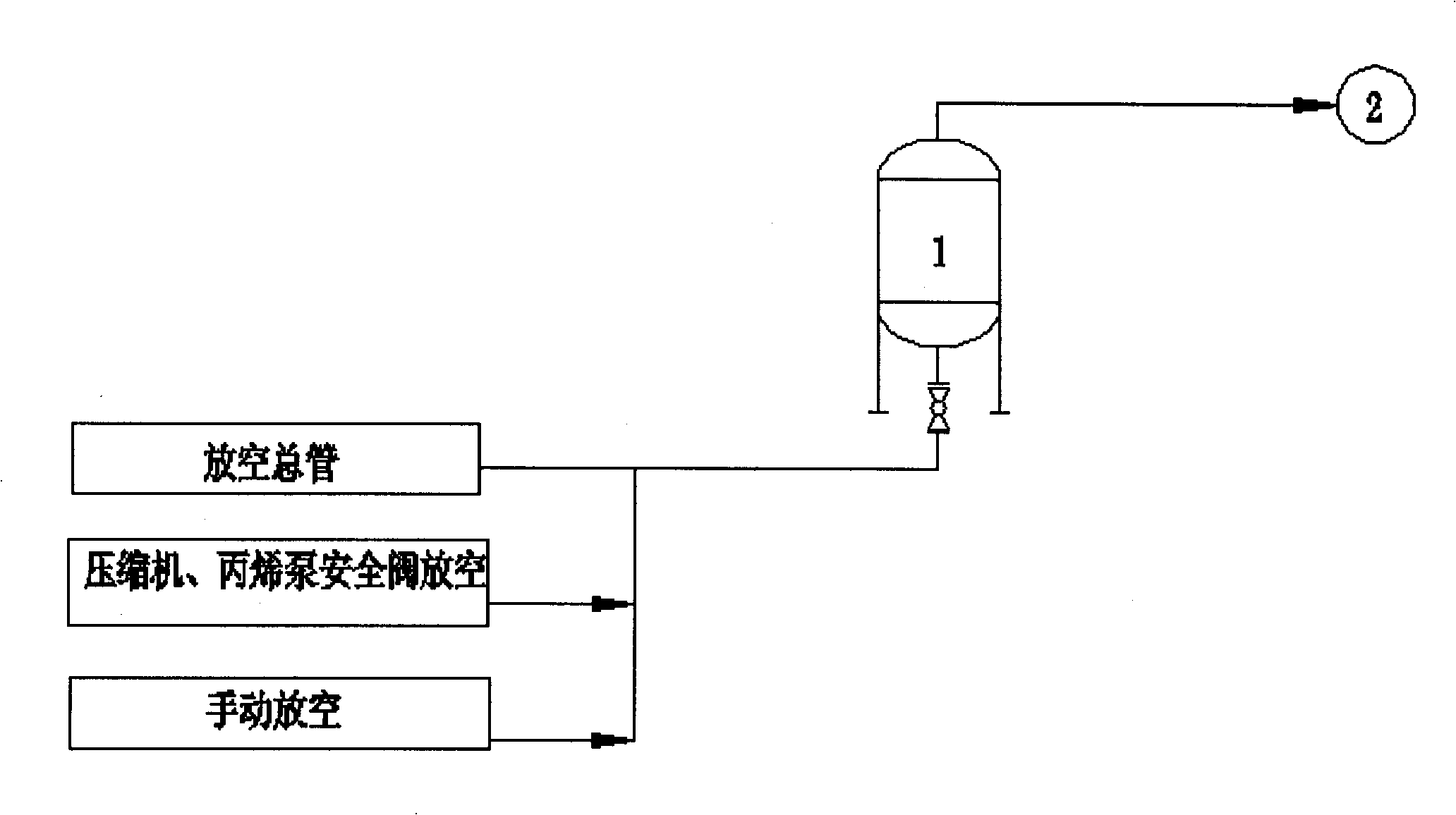

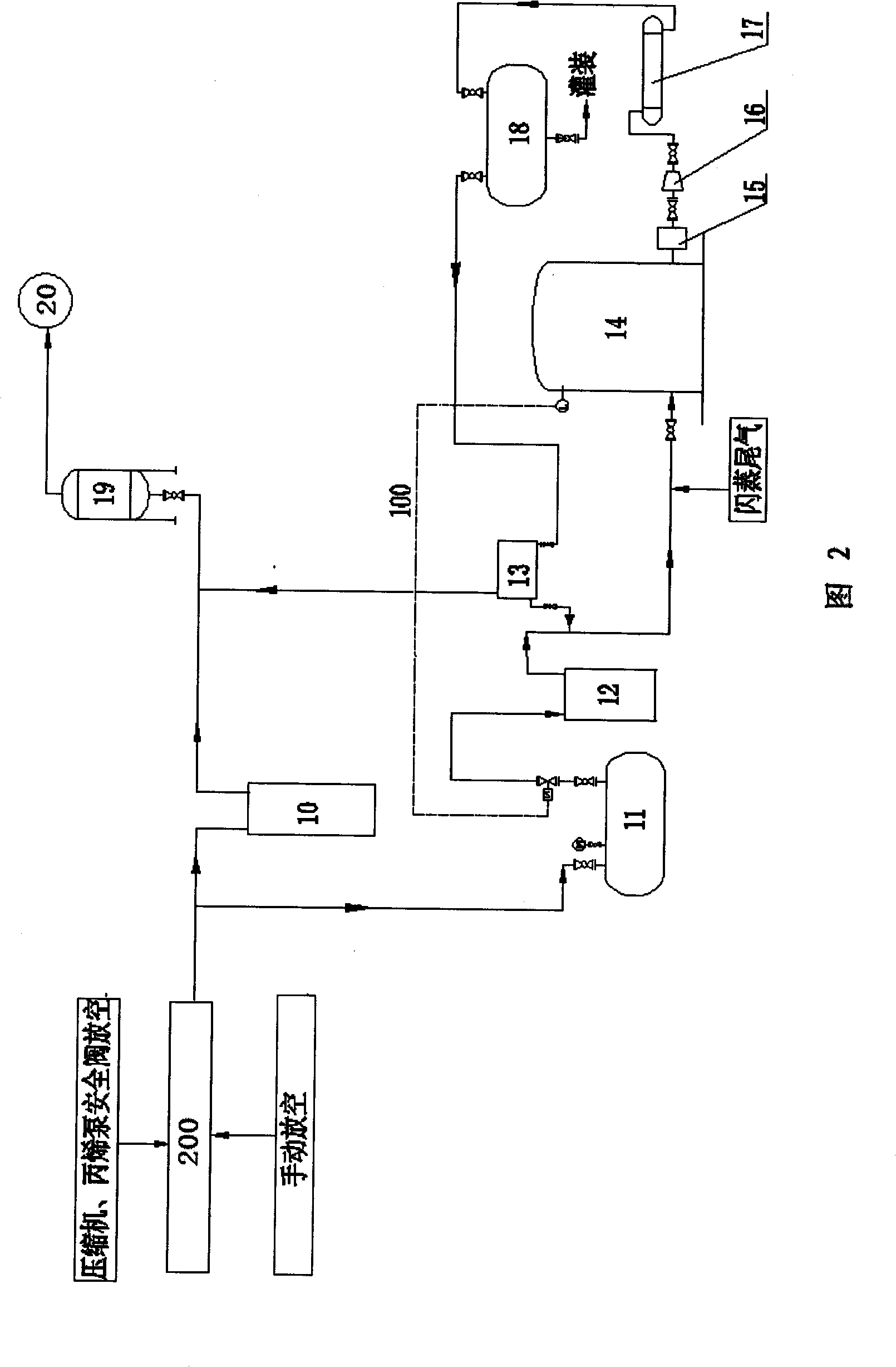

[0011] In actual operation, all the torch gas is first concentrated from the pipeline to the venting main pipe 200, and the torch gas is cut off by the safety protection device 10. The torch gas includes: air release from the safety valve when the polymerizer is in an accident state, and air release from the safety valve in the event of a dryer accident state , On-site exhaust gas of propylene compressor, air release of condenser, air release of safety valve in storage tank accident state, air release in polymerization kettle accident state, air release in activator tank depressurization, air release in catalyst metering tank. When the pressure of these venting gases is less than the pressure designed in the safety protection device 10, the venting gas will enter the recovery buffer tank 11 to collect, and a chain program 100 is designed between the shut-off valve of the recovery buffer tank and the exhaust gas cabinet 14 to ensure the exhaust gas cabinet The pressure is within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com