Multifunctional steam-boiler and control method thereof

A multi-functional, steam boiler technology, applied in pressure cookers, cooking utensils, household appliances, etc., can solve the problems of energy waste and low condensation efficiency, and achieve the effects of preventing heat energy from spreading, improving condensation efficiency, and easy cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

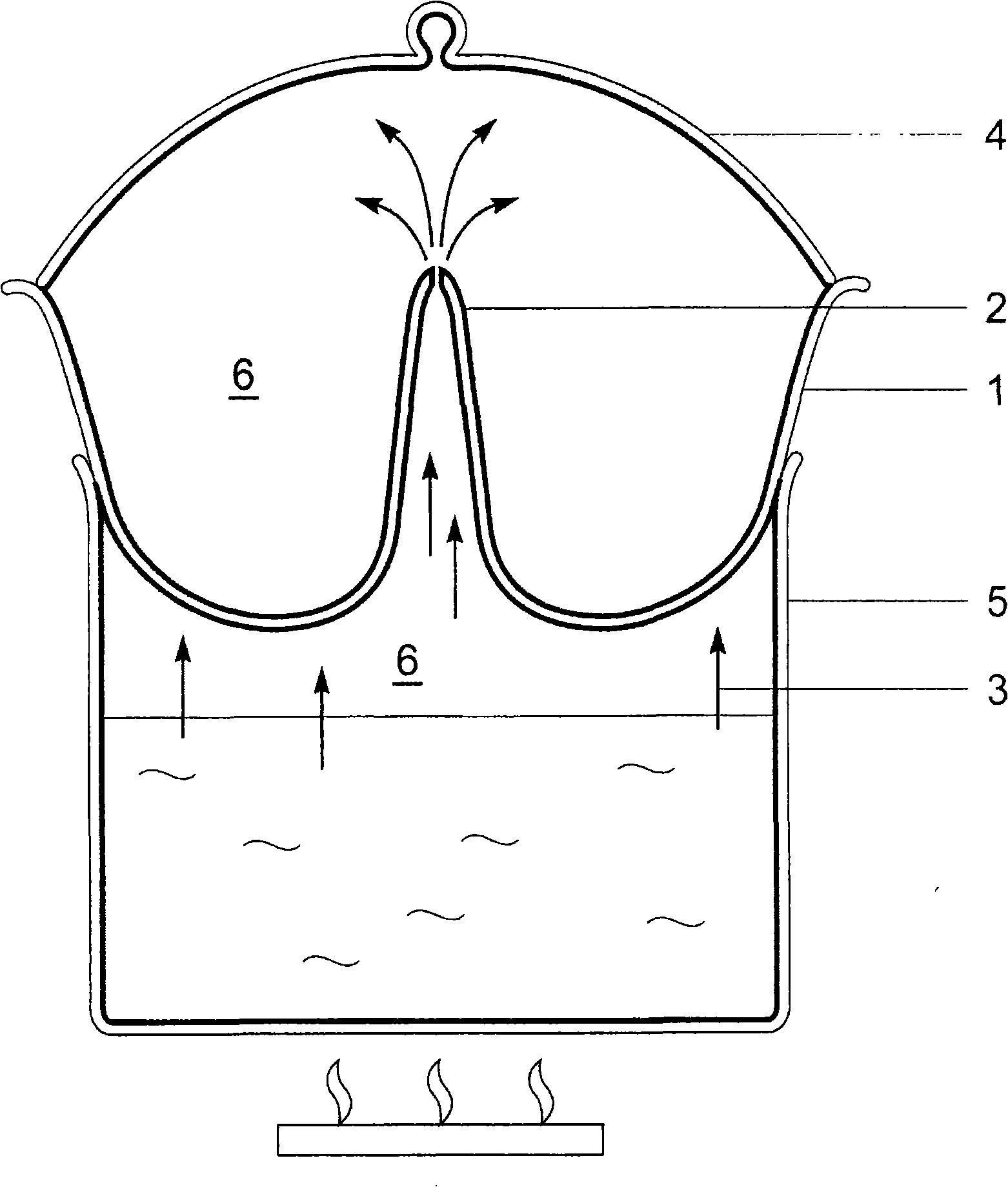

[0054] First explain the principle of Yunnan steam boiler, figure 1 It is an explanatory diagram of the principle of the traditional Yunnan steam boiler. The characteristic of Yunnan steam boiler is the steam nozzle 2 located at the bottom center of the pot body 1, and the steam generator outside the pot body, that is, the cooking pot 5. The steam 3 generated is passed through the steam nozzle 2 , is injected into the inner cavity of the pot body 1 from the bottom of the steam pot to heat the food. There is a pot cover 4 on the upper part of the pot body, and there is a vent hole at the handle of the pot cover 4, not shown in the figure. They are all fired from ceramic materials. figure 1 As shown in the thick black line, the boiler body 1 communicates with the inside of the cooking pot 5 to form a space 6 isolated from the external atmosphere, and the water vapor 3 produced by the cooking pot 5 increases the internal steam pressure of the isolated space 6. The temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com