Downstream type tobacco-dryer exit tobacco-shred water control method

A control method and technology of a silk drying machine, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of conflicting product quality requirements, large temperature fluctuations of the cylinder wall, unstable product internal quality and smoking style, etc., and achieve stability. Effects of control, stability and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

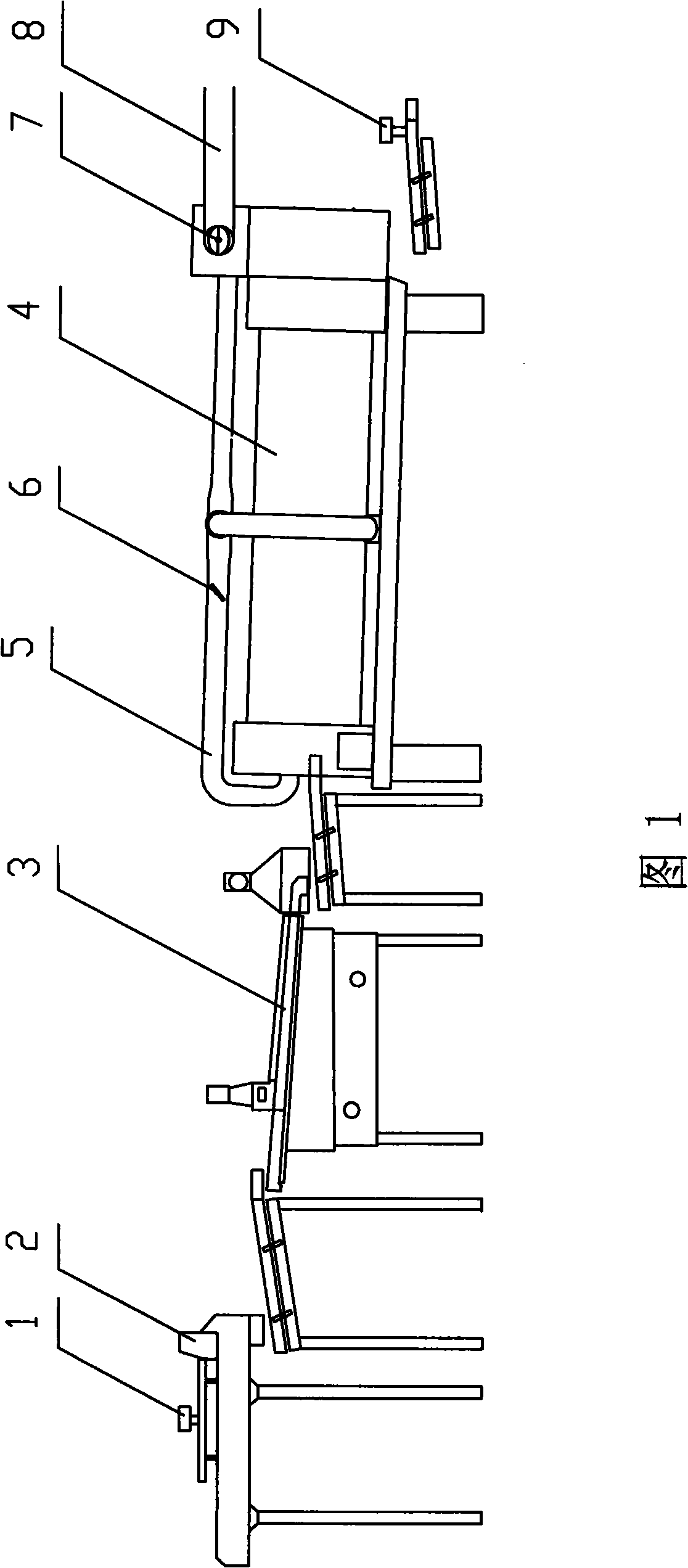

[0024] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Accompanying drawing 1 is the schematic diagram of the system of the parallel flow silk drying machine. The pre-drying moisture meter 1 is used to detect the moisture content of the incoming cut tobacco of the drying machine; the pre-drying electronic scale 2 is a control type electronic scale, and its belt speed can be adjusted. On the contrary, the running speed of the belt will be increased, so as to control the flow of shredded tobacco entering the drying machine to be stable at the set value of the flow rate of the electronic scale; both the hot air damper 6 and the damp damper 7 are connected with the controller, which can be controlled and adjusted; The meter 9 is used to detect the moisture content of cut tobacco at the outlet of the drying machine. Silk drying machine 4, ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com