Intelligent heat exchange system of diesel

A technology of heat exchange system and diesel engine, which is applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of low utilization rate of diesel oil, energy waste, etc., and achieve the effect of reducing transportation costs, saving energy consumption, and setting finely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

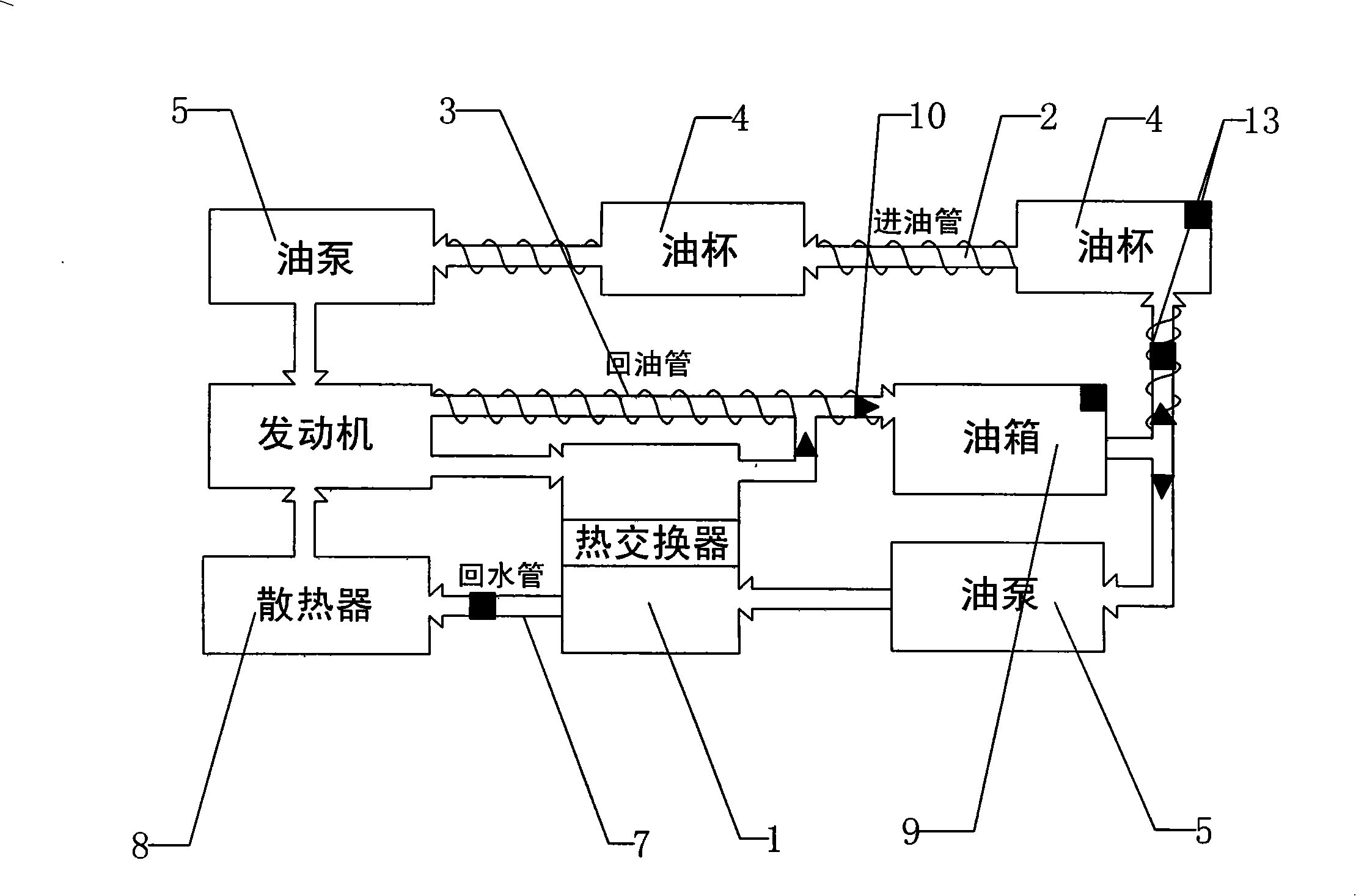

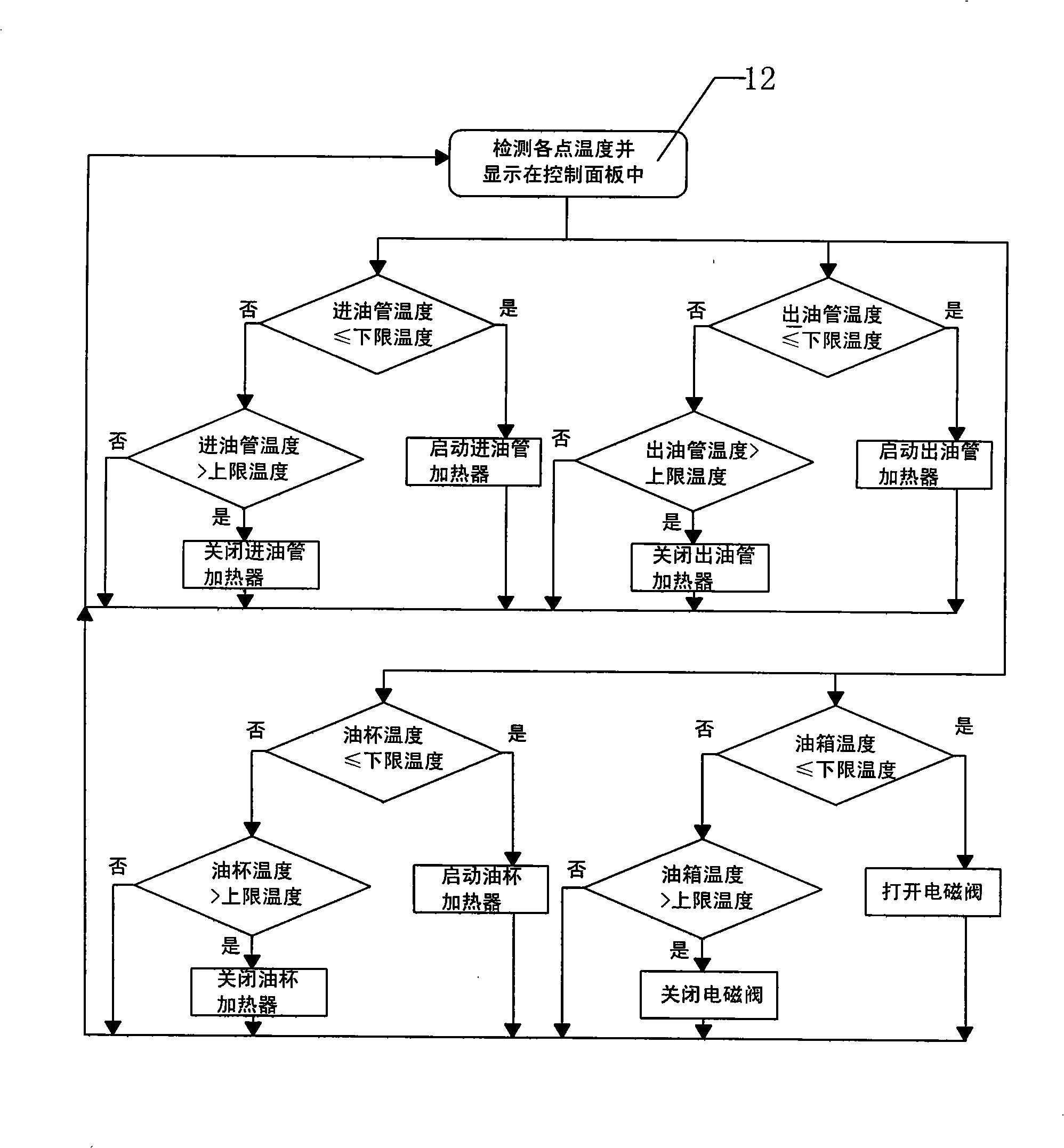

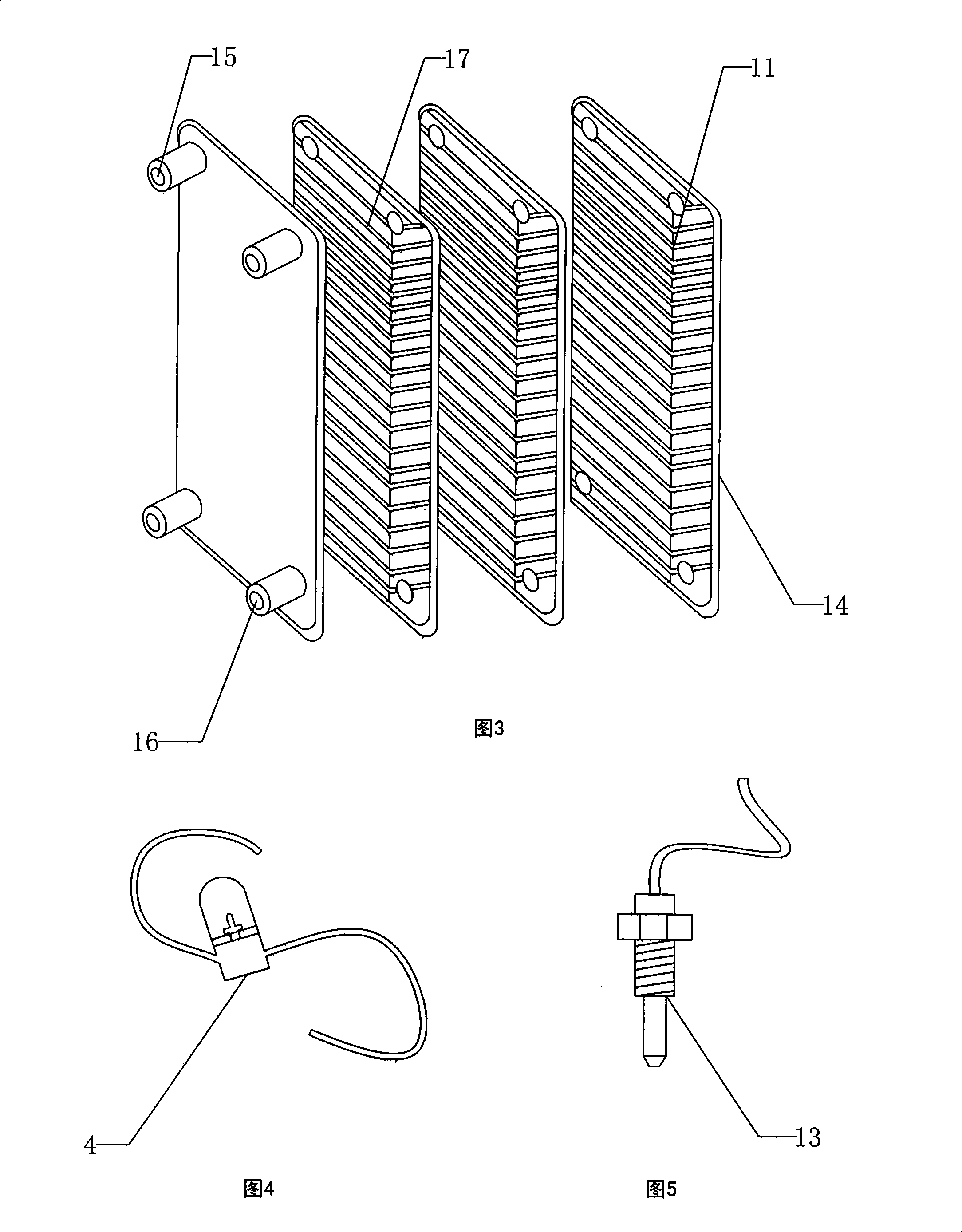

[0024] Such as figure 1 As shown in -5, a diesel engine intelligent heat exchange system according to the embodiment of the present invention includes a heat exchanger 1, a solenoid valve 10, an oil circuit heater and an intelligent monitoring device 12; the heat exchanger 1 includes several cooling fins 14. Two medium inlet pipes 15, two medium outlet pipes 16, the two ends of the cooling fin 14 are respectively connected with two medium inlet pipes 15 and two medium outlet pipes 16, the medium inlet pipes 15 and the medium outlet pipes 16 are respectively arranged in the heat dissipation At the four corners of the sheet 14, the heat sink 14 is composed of two baffle sheets and a corrugated sheet 11, and the front and back sides of the corrugated sheet 11 are provided with corrugated grooves 17; the heat exchanger 1 communicates with the oil pump 5, engine 6. The oil tank 9 communicates with the radiator 8, one end of the engine 6 is connected to the oil pump 5 through the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com