Tyre

A tire, tire width direction technology, applied in tire parts, tire tread/tread pattern, tire sidewall, etc., can solve the problems of reducing tire service life, wasting raw materials, affecting tire stability, etc., to achieve puncture resistance Enhanced performance and stability, extended service life, and the effect of avoiding tire scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

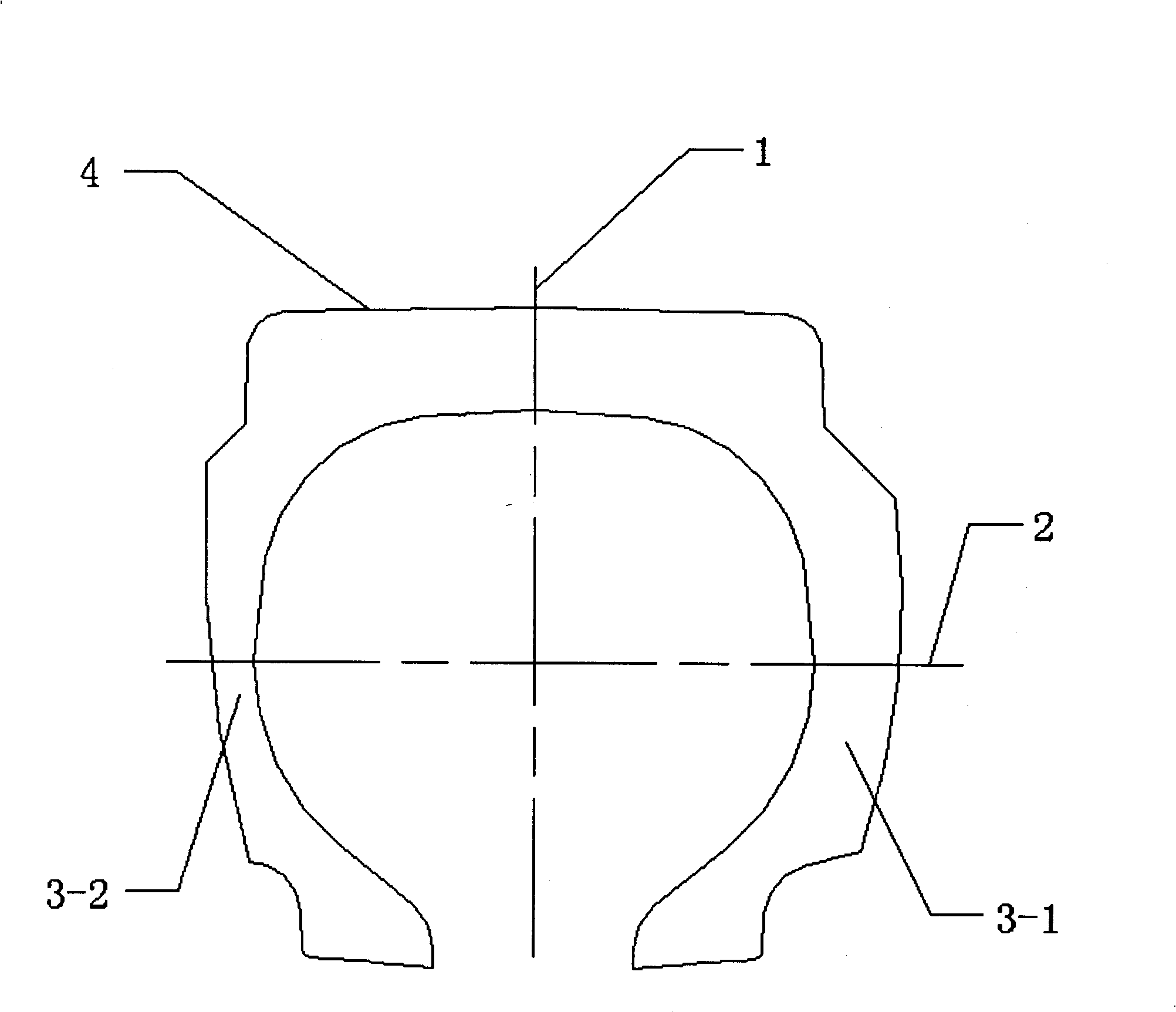

[0014] Such as figure 1 It is a sectional view of a tire in the width direction according to the present invention. A hypothetical axis of symmetry 1 divides the tire into two halves, each of which includes a crown, a shoulder, a sidewall and a bead from top to bottom. The upper surface of the crown is the tread 4 of the tire. The tire has an asymmetrical profile in cross-section, that is, the above-mentioned two half areas are asymmetrical with respect to the axis of symmetry 1, and one half area is set as a normal sidewall 3-2, the other half area is the reinforced sidewall 3-1, the thickness of the reinforced sidewall 3-1 measured in the tire width direction is greater than that of the normal sidewall 3-2 on the same plane relative to the tire width direction The thickness measured above. For this embodiment, the thickness measured at the horizontal axis 2 of the normal sidewall 3-2 of the tire is 8-15 mm, while the thickness measured at the horizontal axis 2 of the reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com