Hot melt adhesive composition

A composition, hot melt adhesive technology, applied in the direction of adhesives, etc., can solve the problems of peeling or gelation, easy coking, poor temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

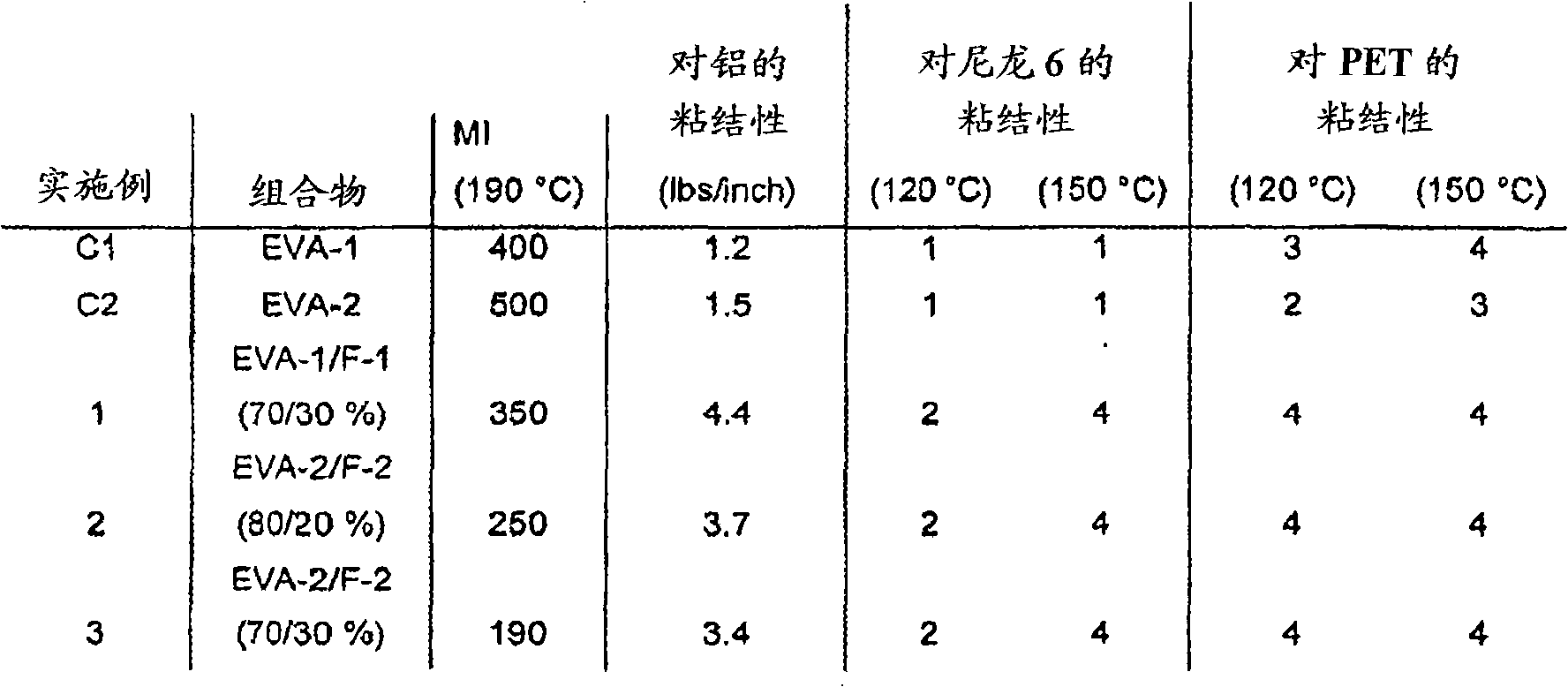

[0121] materials used

[0122] Nylon 6 is available as ULTRAMID B3 from BASF.

[0123] Polyethylene terephthalate (PET) is available under the trade name CRYSTAR 3924 from DuPont.

[0124] EVA-1 is a MI 400 ethylene / vinyl acetate copolymer (28 wt% VA).

[0125] EVA-2 is a MI 500 ethylene / vinyl acetate copolymer (18 wt% VA).

[0126] F-1 is an ethylene / maleic anhydride copolymer (E / MAH 85 / 15 wt %) having a MI of 205 and a melting point of 104°C.

[0127] F-2 is an ethylene / monoethyl maleate copolymer (E / MAME 90.5 / 9.5 wt %) having a MI of 30 and a melting point of 108°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com