Semiconductor device and method of fabricating the same

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increase and deterioration of retention characteristics, and achieve the effect of preventing movable ions from moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

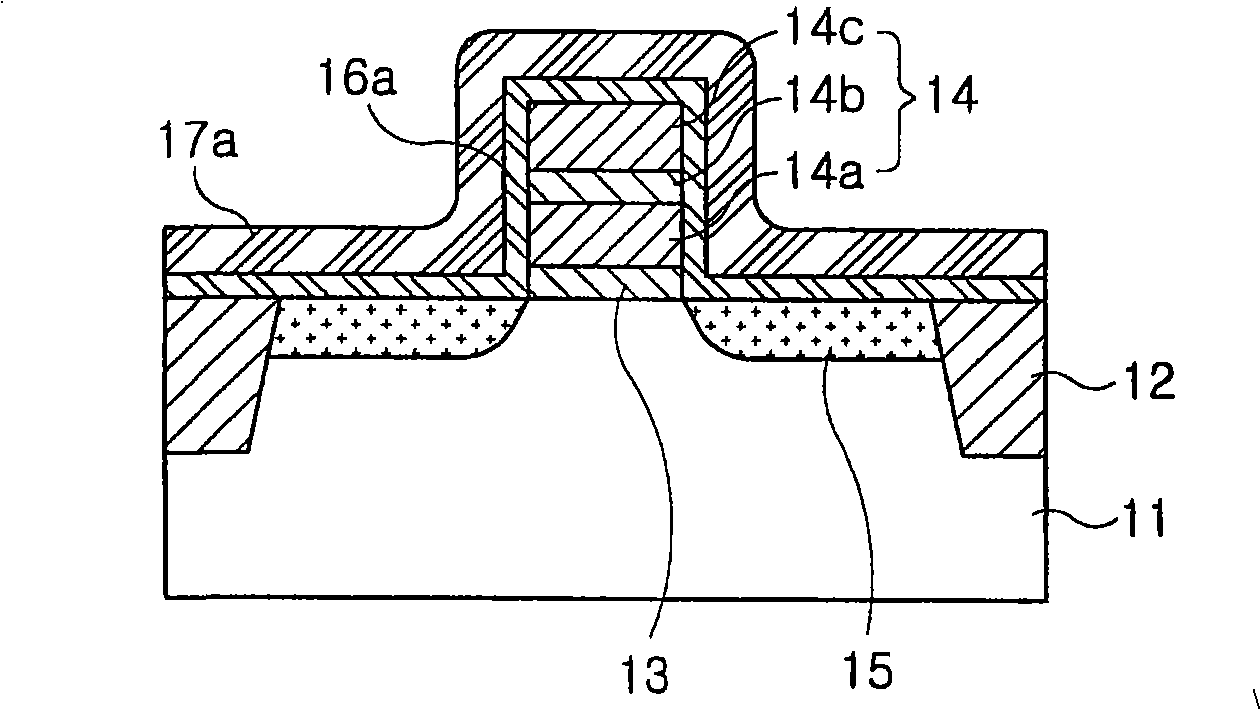

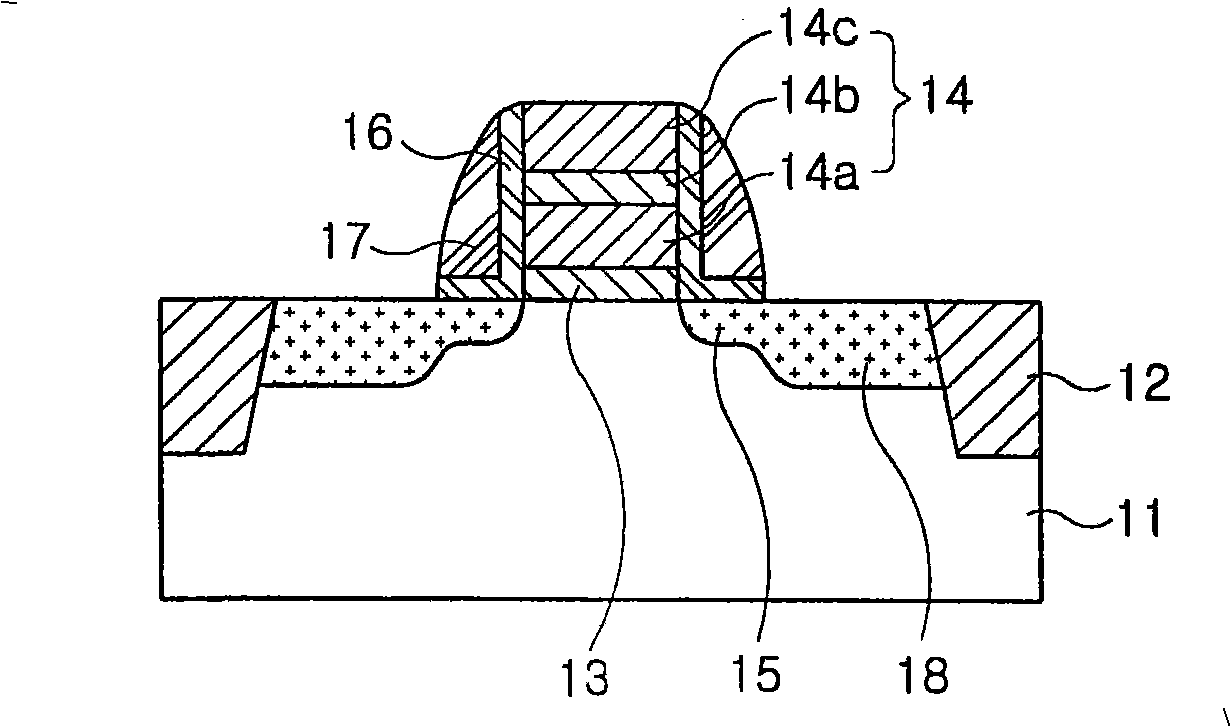

[0020] A method of manufacturing a semiconductor device such as a flash memory device is provided, wherein a blocking nitride layer is given compressive stress using an ion implantation process to prevent movement of mobile ions. Thus, the effects of charge loss and charge gain in the flash memory device are minimized.

[0021] Such as Figure 2A As shown in the example in FIG. 1 , gate insulating layer 103 and gate electrode 104 are formed on and / or over the active region of semiconductor substrate 101 defined by isolation layer 102 . A lightly doped (LDD) region 105 having a shallow trench isolation (STI) structure may be formed in an active region of the semiconductor substrate 101 .

[0022] In order to form the isolation layer 102, a pad insulating layer having a predetermined thickness may be formed on and / or over the semiconductor substrate 101, and then the pad insulating layer is etched by a photolithography process and an etching process using an isolation mask to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com