Novel natural rubber production method

A technology of natural rubber and a new method, applied in the field of natural rubber production, can solve the problems of less than 15% heat energy utilization rate, environmental pollution, serious problems, etc., and achieve the effect of quality improvement, uniform temperature rise, and no dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A new method for producing natural rubber, the specific process steps are:

[0022] The first step of coagulation: the fresh-keeping glue collected from the rubber tree is sent to the factory by tanker, diluted with water, stirred and homogenized, and after removing impurities such as sediment and bark, it is pumped into the coagulation kettle, and coagulant and coagulant are added while stirring. Surfactants, under the action of stirring blades, make the colloidal components condense into granules in the kettle, and then let the colloidal water containing gel particles pass through a vibrating sieve to remove water;

[0023] The second step of drying: the screened rubber material enters the screw extrusion puffing dryer, using the basic principle of friction heat generation, mechanically rubs the rubber particles under the extrusion and shearing action of the screw, and the rubber material itself is mechanically rubbed However, the pressure and temperature rise rapidly...

Embodiment 2

[0026] A new method for producing natural rubber, the specific process steps are:

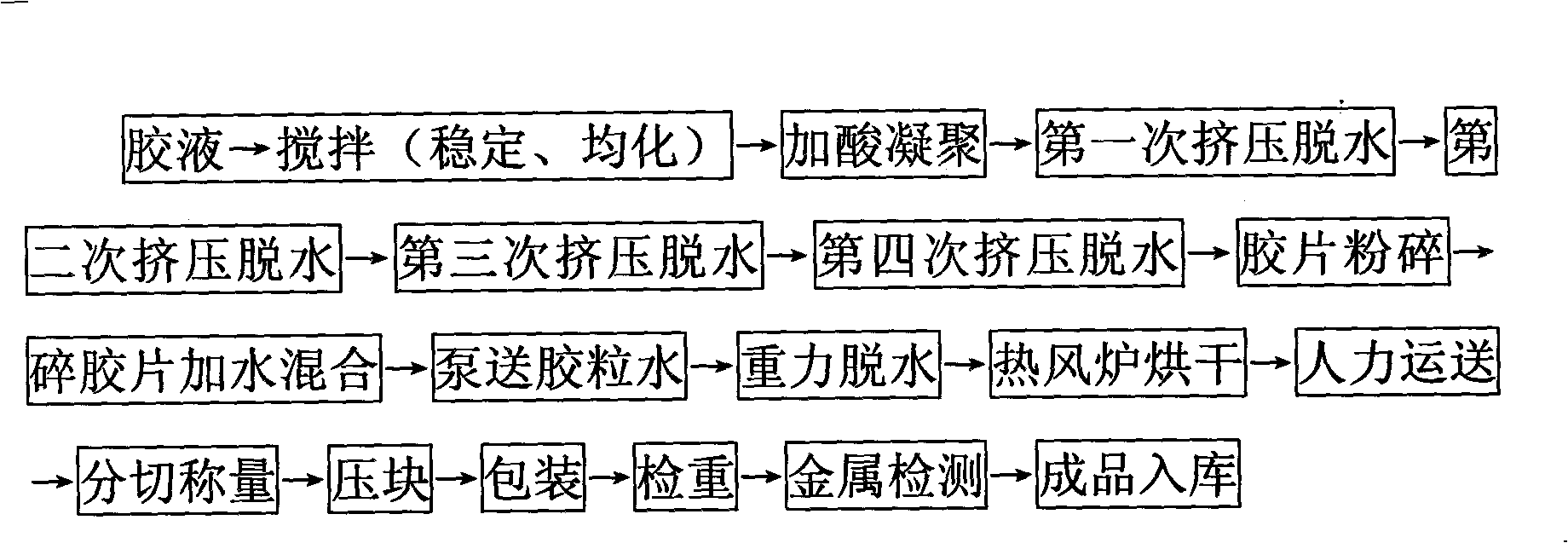

[0027] The first step of coagulation: using traditional technology, the fresh-keeping glue collected from rubber trees is sent to the factory by tanker, diluted with water, stirred and homogenized, after removing impurities such as sediment and bark, poured into the gel tank, and added coagulant (mainly acid coagulant) coagulation, after gelation, a large amount of water is removed through three to four double-roller extrusion dehydration processes to become thin films, and the extruded dehydrated films are crushed into small pieces with a pulverizer, screen;

[0028] The second step and the third step are the same as in Example 1.

Embodiment 3

[0030] A new method for producing natural rubber, the specific process steps are:

[0031] The first step of coagulation: the fresh-keeping glue collected from the rubber tree is sent to the factory by tanker, diluted with water, stirred and homogenized, and after removing impurities such as sediment and bark, biological gel is used to add biological strains and nutrient solution to the rubber , The gel is completed after the natural existence time, and the gel is crushed to a dryable particle size.

[0032] The second step and the third step are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com