Preparation of homocystine

A technology of homocystine and methionine, applied in hydrogenated polysulfide/polysulfide preparation, organic chemistry, etc., can solve a large amount of solid waste wastewater, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

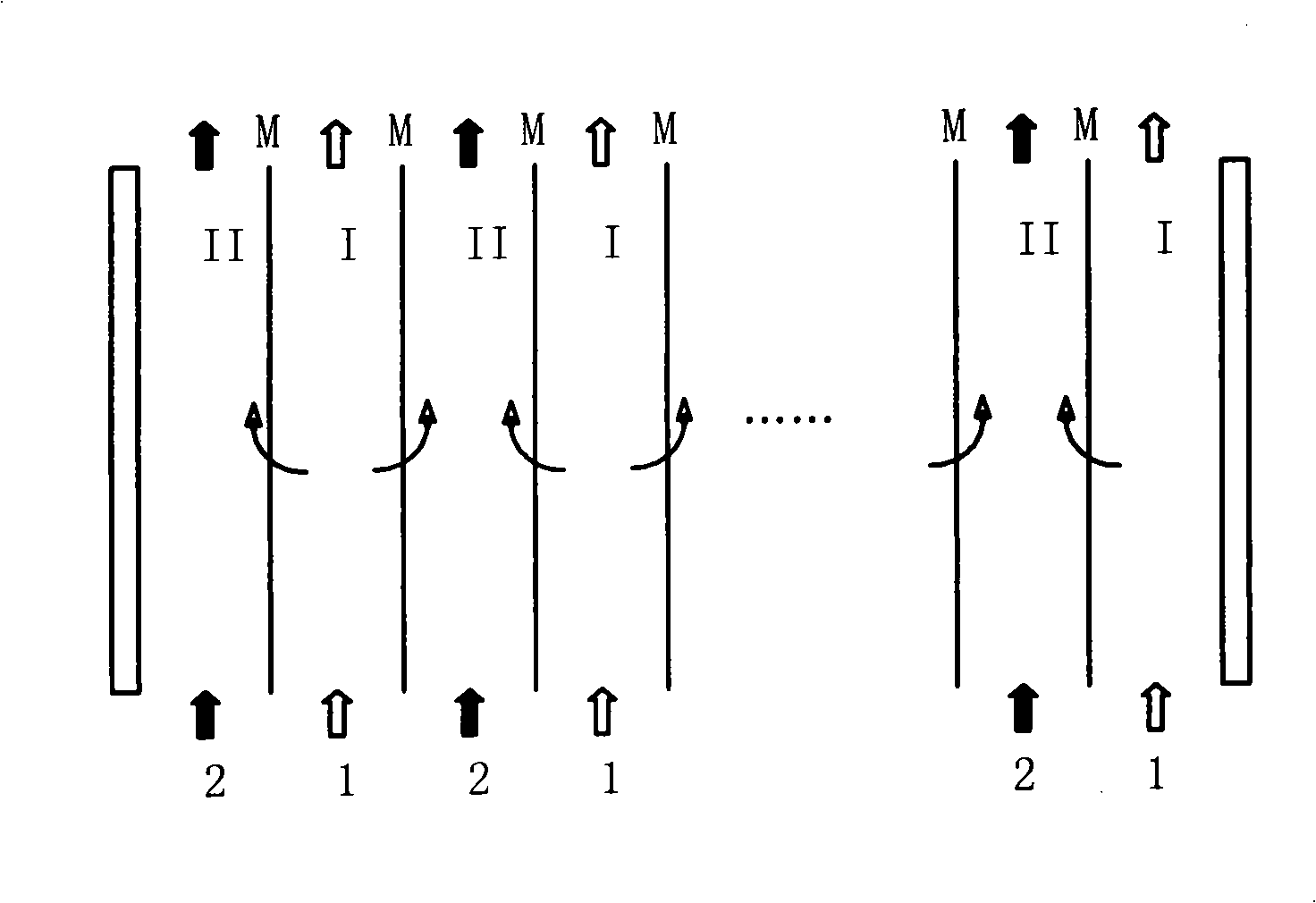

[0063] Heat 40g DL-methionine and 120ml 9mol / L sulfuric acid solution at 125-135°C for 6 hours, cool to room temperature, add 100ml water to dilute to reduce viscosity, and obtain about 200ml reaction solution with sulfuric acid concentration of 4.5mol / L , this reaction solution enters as figure 1 In the stock solution chamber of the diffusion dialysis device shown, 300ml of pure water enters the recovery chamber of the diffusion dialysis device. After 24 hours of diffusion dialysis, the recovery chamber obtains 250ml of sulfuric acid with a sulfuric acid concentration of 1.08mol / L, and the recovery rate of sulfuric acid is about 30%. . The reaction solution obtained in the stock solution chamber is 250ml, and the concentration of sulfuric acid is about 2.5mol / L. After the solution obtained in the stock solution chamber is adsorbed and decolorized by activated carbon, it is neutralized with 30% sodium hydroxide solution until the pH value is about 7, and a total of 125ml of 3...

Embodiment 2

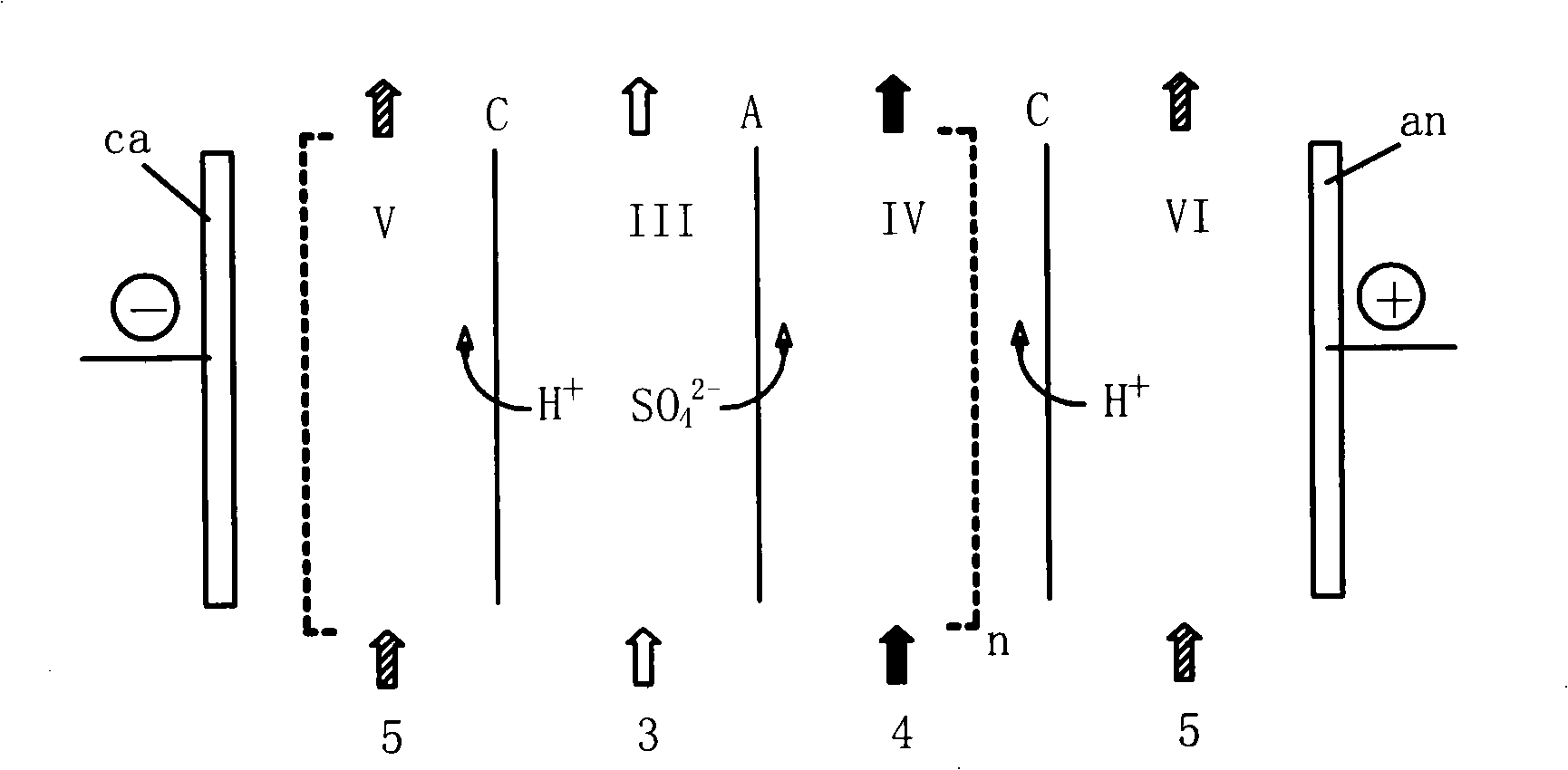

[0065] Heat 40g DL-methionine and 120ml 14mol / L sulfuric acid solution at 105-115°C for 3 hours, cool to room temperature, add 100ml water to dilute to reduce viscosity, and obtain about 200ml reaction solution with sulfuric acid concentration of 7.5mol / L , this reaction solution enters as figure 2 In the dilute chamber of the electrodialysis device shown, 250ml of sulfuric acid solution with a concentration of about 0.3mol / L enters the concentrated chamber, and the liquid in the electrode chamber is 1mol / L sulfuric acid solution. 2 The electric current density electrodialysis 48 hours, reclaims the sulfuric acid that 340ml concentration is 3.56mol / L in the concentration room, and the sulfuric acid recovery rate is about 75%, and average current efficiency is 52.4%. After the solution in the light chamber is adsorbed and decolorized by activated carbon, it is neutralized to about pH 7 with 30% sodium hydroxide solution, and a total of 75 ml of 30% sodium hydroxide solution is...

Embodiment 3

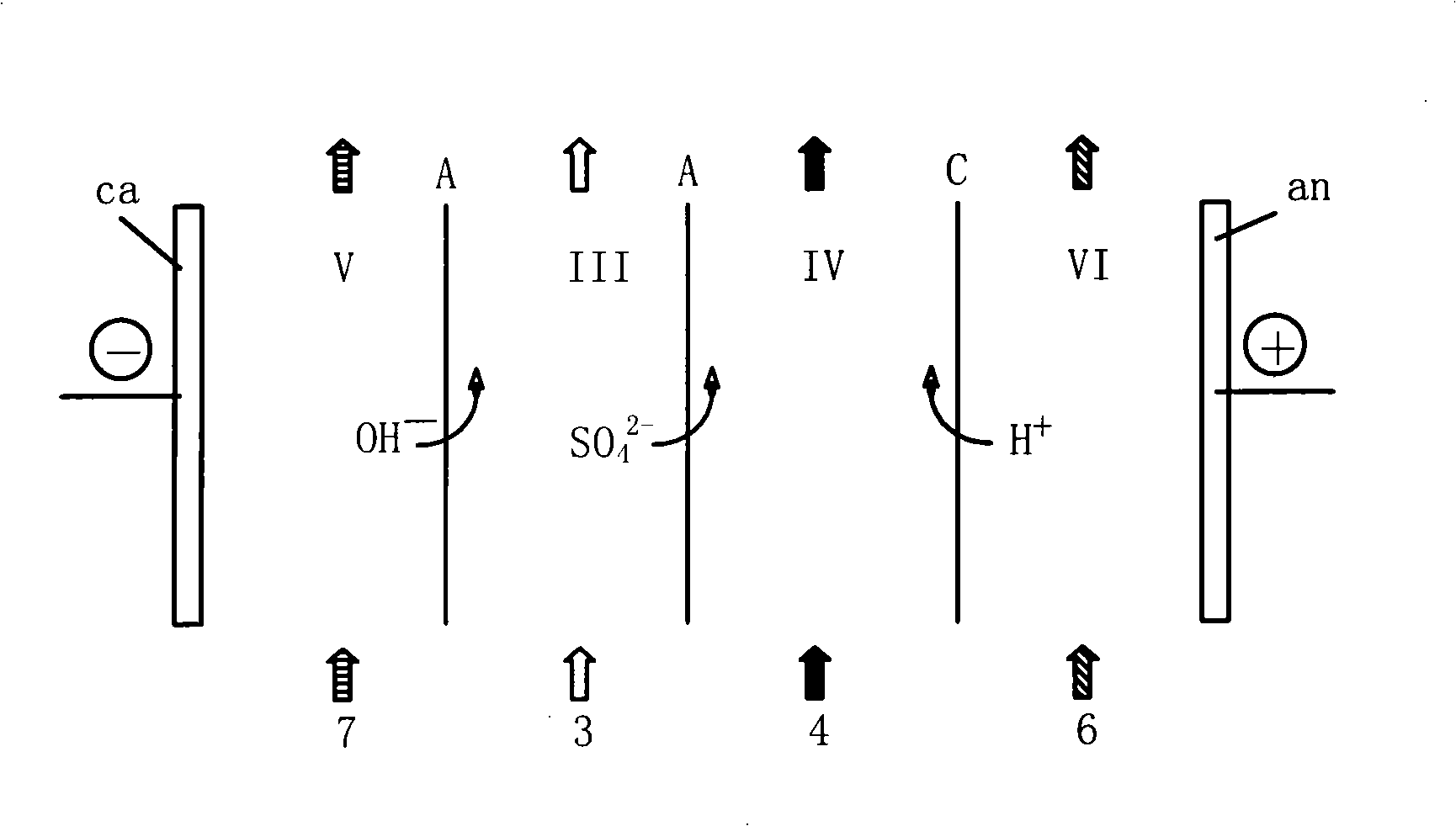

[0067] Heat 40g DL-methionine and 120ml 6mol / L sulfuric acid solution at 135-145°C for 18 hours, cool to room temperature, add 100ml water to dilute to reduce viscosity, and obtain about 200ml reaction solution with sulfuric acid concentration of 2.7mol / L , this reaction solution enters as image 3 In the dilute chamber of the electrodialysis device shown, 250 ml of sulfuric acid solution with a concentration of about 0.3 mol / L enters the concentrated chamber, the anolyte is 1 mol / L sulfuric acid solution, and the catholyte is 1 mol / L sodium hydroxide solution. , at 2A / dm 2 Electrodialysis at a high current density for 65 hours until the pH of the solution in the dilute chamber is about 7. 320ml of sulfuric acid with a concentration of 1.82mol / L was recovered in the concentrated chamber, the recovery rate of sulfuric acid was about 92%, and the average current efficiency was 34.7%. A large amount of solid homocystine has precipitated out of the solution in the light chamber....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com