Method and device for compressing numerical control machining parts

A technology of parts and extruded bodies, which is applied in the fields of compression and clamping methods and clamping devices for parts in numerical control machining, can solve the problems of unfavorable parts processing quality, long clamping time, low efficiency, etc., and achieve simple structure, The effect of shortening the overhang length and making it easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

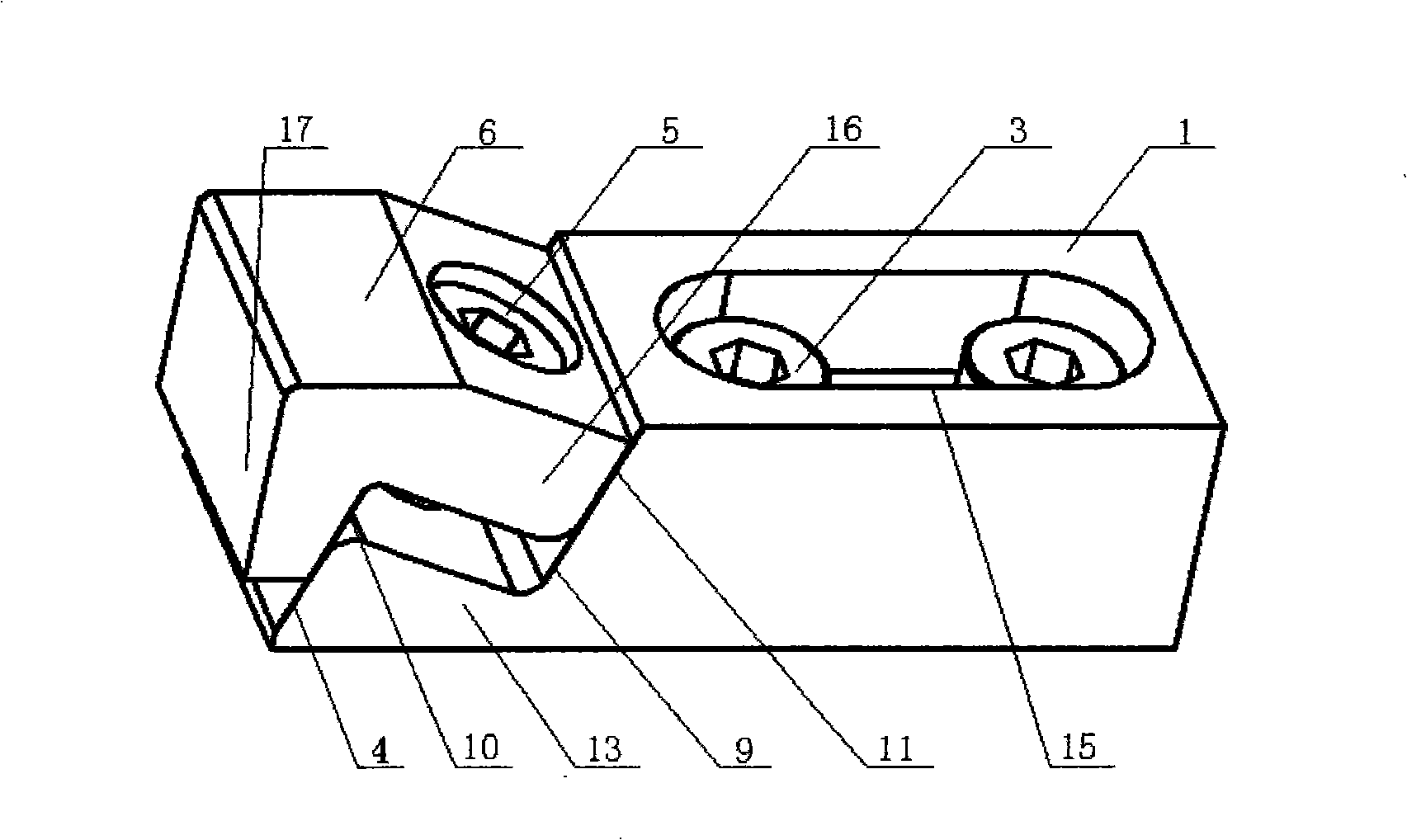

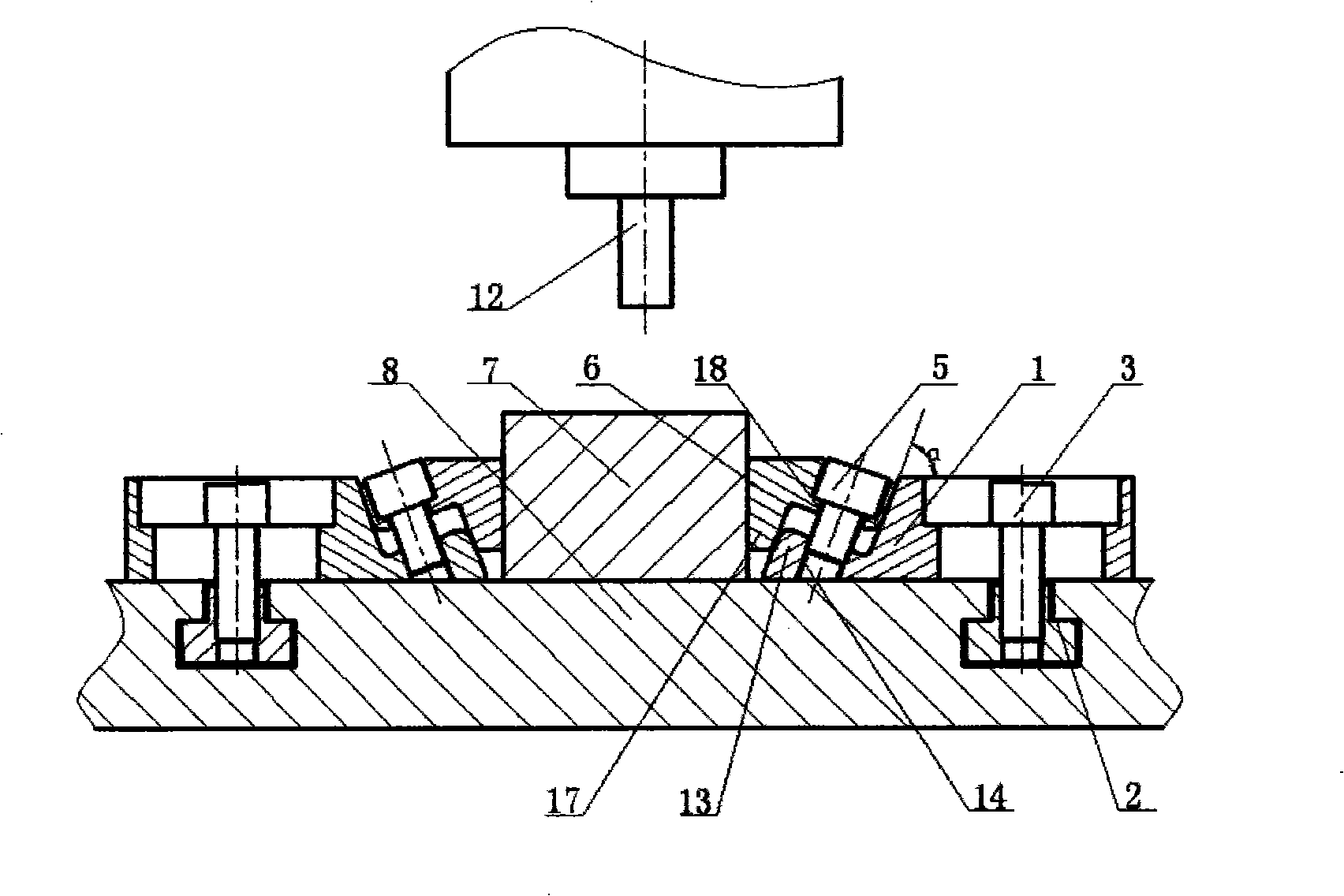

[0014] See attached figure 1 , The pressing device includes a fixed pressing block 1 and a movable pressing block 6 . The fixed pressing block 1 is composed of a fixed body and a connecting platform 13 as an integral assembly. The fixed pressing block 1 is provided with two parallel fixed slopes 4 and 9. The bottom of the fixed body protrudes from the connecting platform, and the outer side of the connecting platform 13 forms a fixed inclined surface. 4. The transition between the connection platform 13 and the fixed body is the fixed slope 9, the fixed slope 4 and the fixed slope 9 are parallel to each other, the fixed body has a vertical fixing hole 15, and the connection platform 13 is provided with a connection hole 14 parallel to the fixed slope The body of the above-mentioned movable briquetting block 6 is a corner-shaped structure composed of a connecting body 16 and a wedge-shaped extruding body 17, and the movable briquetting block 6 is provided with two movable incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com