Arc assisted activating gas tungsten arc welding method

A technology of argon tungsten arc welding and argon tungsten arc, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems affecting the stability of welding process and welding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The thickness of the stainless steel plate is 10mm, and AA-TIG welding is carried out by single-arc welding process, that is, the welding process is divided into two processes. The first process uses active mixed gas as the shielding gas, and pre-melts the surface of the bead to be welded with a small current tungsten arc. , the second process is TIG welding. The protective gases are active mixed gas oxygen + argon and carbon dioxide + argon respectively, and the purity of oxygen, carbon dioxide and argon is 99.9%. The specification parameters of small current tungsten arc are shown in Table 1, and the welding specifications of TIG welding are shown in Table 2.

[0011] Table 1 Specification parameters of small current argon tungsten arc

[0012]

[0013] Two active mixed gases of oxygen + argon and carbon dioxide + argon were respectively used as protective gases, and the surface of the bead to be welded was pre-melted by a low-current tungsten argon arc with the s...

Embodiment 2

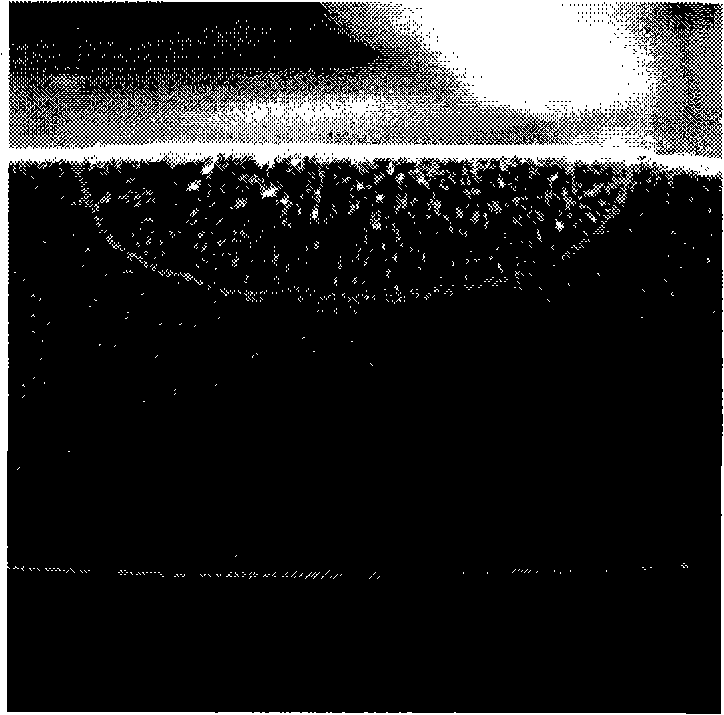

[0015] AA-TIG welding is performed using a single arc welding process. Carbon dioxide + argon is used as the active mixed protective gas, in which the purity of carbon dioxide and argon is 99.9%, and the surface of the weld bead to be welded is pre-melted by a low-current tungsten argon arc with the specification parameters shown in Table 3. Then use the standard parameters shown in Table 4 to carry out TIG welding, which can penetrate a 10mm thick stainless steel plate at one time, realize single-sided welding and double-sided forming, the back reinforcement is less than 2mm, and the weld surface is well formed, such as Figure 4 , Figure 5 and Figure 6 shown. However, the cross-sectional appearance of the weld seam when conventional TIG welding is performed with the welding specification parameters shown in Table 4 is as follows: Figure 7 shown. Compared with conventional TIG welding, there is almost no change in the microstructure of the weld zone of AA-TIG welding, ...

Embodiment 3

[0019] Carbon dioxide + argon is used as the active mixed protective gas, and the purity of carbon dioxide and argon is 99.9%. The double-arc welding process is used for AA-TIG welding, that is, two TIG welding torches are arranged one behind the other, the former welding torch is used for low-current tungsten argon arc pre-melting treatment, and the latter welding torch is used for TIG welding. The distance between the two TIG torches is 25mm. The standard parameters of the low-current argon tungsten arc are shown in Table 1. The welding specification of TIG welding is the same as the welding speed of the low-current argon tungsten arc, which is 125mm min -1 Except, the rest of the specification parameters are the same as those in Table 2. When welding, two welding torches work at the same time, and the appearance of the welding arc is as follows: Figure 8 shown.

[0020] When double-arc AA-TIG welding is performed under such welding specifications, the surface morphology...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com