Solid acid catalyst and reaction technique for synthesis of allantoin

A solid acid catalyst, catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex process routes, special reaction raw materials, inorganic strong acid catalyst corrosion, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Prepare 100ml of ammonia water with a volume percentage of 2.5%, add 100ml of zirconium oxychloride solution with a concentration of 0.15mol / L dropwise under stirring, continue stirring for 2h after the dropwise addition, age for 24h, wash with deionized water until no chloride ions are detected, Add an appropriate amount of dilute sulfuric acid solution to make the pH of the system equal to 2 to obtain a transparent sol containing zirconium hydroxide, and then add WO 3 Powder, stir well and disperse evenly, put it in a 100°C oven for 12 hours and bake at 600°C for 4 hours to obtain ZrO 2 Composite carrier with a content of 53.6 wt%. According to the ratio of load liquid volume / carrier weight of 20ml / g, it is impregnated with 1M ammonium sulfate solution for 2h, filtered and dried at 100°C for 10h, and then roasted at 600°C for 4h to obtain SO 4 2- / ZrO 2 -WO 3 Composite solid superacid catalyst.

[0019]The obtained catalyst is used for the synthesis of allantoin,...

Embodiment 2

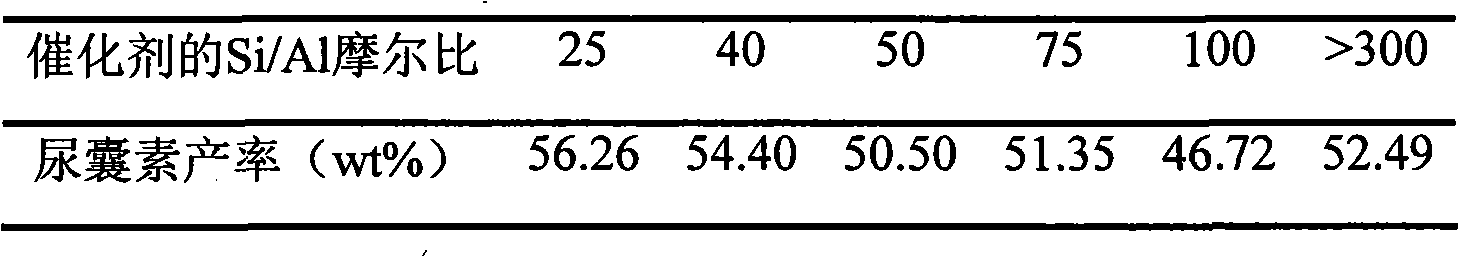

[0021] Prepare 100ml of ammonia water with a volume percentage of 2.5%, add 100ml of zirconium oxychloride solution with a concentration of 0.15mol / L dropwise under stirring, continue to stir for 2h after the dropwise addition, then leave it to age for 24h, separate the precipitate, and use deionized Wash well with water. The washed precipitate is redispersed in a small amount of deionized water, and an appropriate amount of dilute sulfuric acid solution is added to make the pH of the system equal to 2, and a transparent sol containing zirconium hydroxide is obtained. Add HZSM-5 molecular sieve to the sol, stir and disperse evenly, then dry at 100°C for 12 hours and roast at 550°C for 4 hours to obtain ZrO 2 Composite carrier with a content of 25% by weight. According to the ratio of loading liquid volume / carrier weight of 15ml / g, the carrier is impregnated and loaded with a sulfuric acid solution with a concentration of 0.5M, and the loading time is 2h. After filtration, th...

Embodiment 3

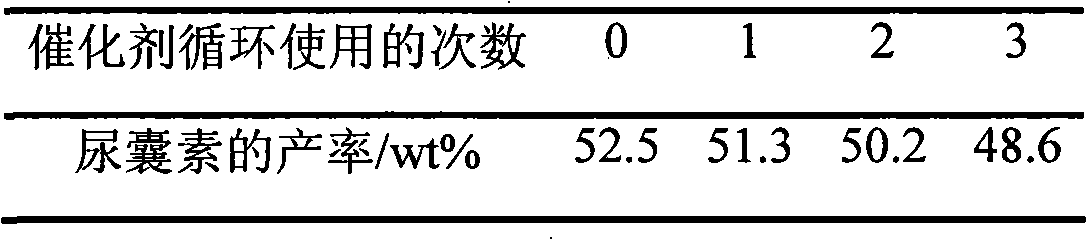

[0027] Prepare 100ml of ammonia water with a volume percentage of 2.5%, add 100ml of zirconium oxychloride solution with a concentration of 0.15mol / L dropwise under stirring, continue stirring for 0.5h after the dropwise addition, age for 24h, and wash with deionized water until no chloride ions can be detected , the obtained gel was dried at 100°C for 12 hours, after grinding, it was impregnated with 0.5M sulfuric acid solution for 4 hours according to the ratio of load liquid volume / carrier weight of 15ml / g, filtered, dried at 110°C for 12 hours, and then calcined at 600°C for 3 hours to obtain SO 4 2- / ZrO 2 solid acid catalyst.

[0028] The obtained catalyst is applied to the preparation of allantoin, and the reaction conditions are the same as in Example 2. After the reaction, the resulting mixture was cooled to room temperature and filtered with suction. The resulting filter cake was redispersed in hot water and suction filtered while it was hot. The filter cake is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com