Controller for direct injection engine

一种控制器、发动机的技术,应用在发动机控制、燃烧发动机、机器/发动机等方向,能够解决不能充分地减少排放、燃料燃料量不能有效地被减少等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described below.

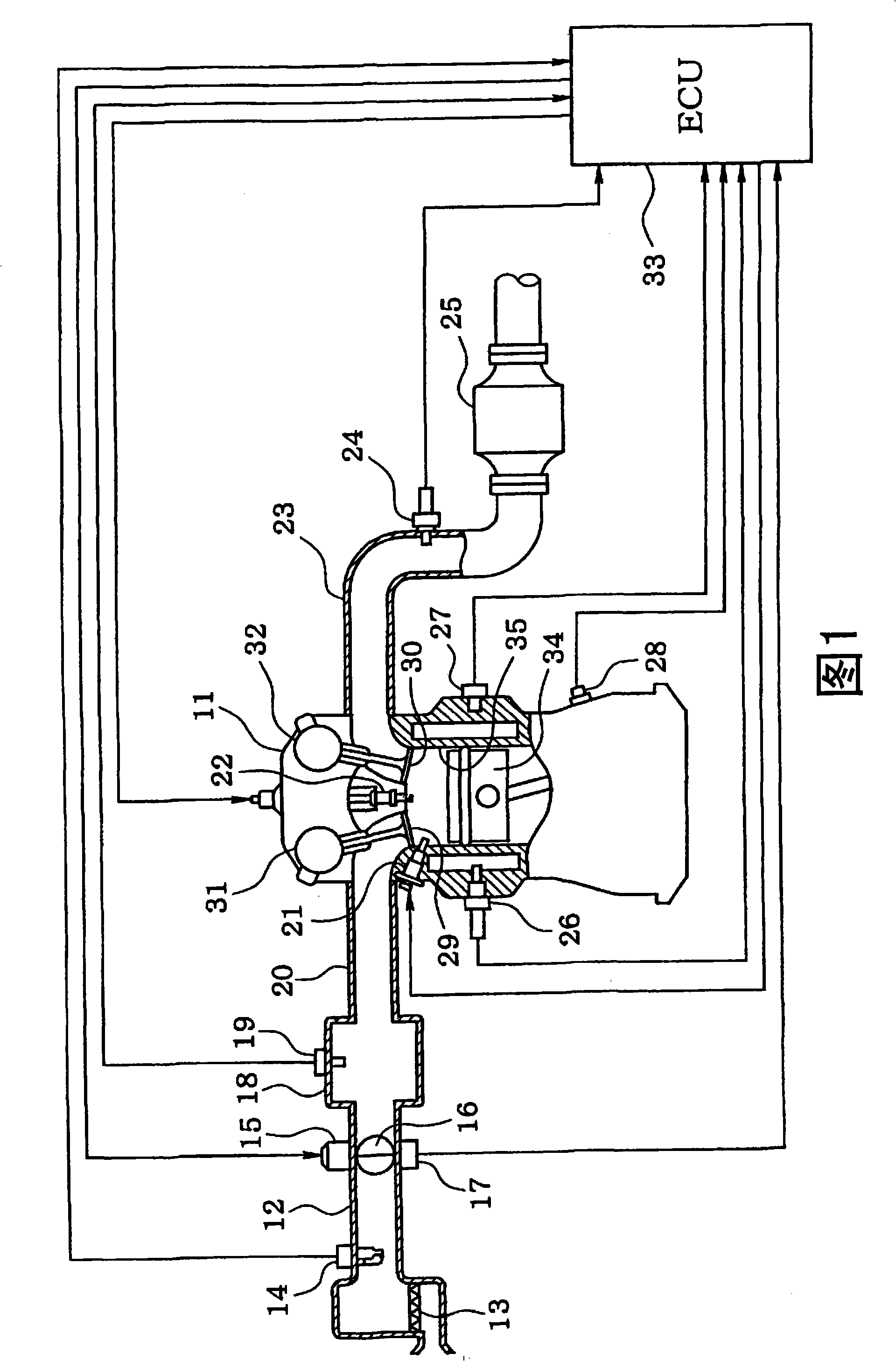

[0018] Referring to Fig. 1, an engine control system is explained. The air cleaner 13 is arranged upstream of the intake pipe 12 of the internal combustion engine 11 , which is a direct injection engine. An air flow meter 14 that detects the flow rate of intake air is provided on the downstream side of the air cleaner 13 . A throttle valve 16 driven by a DC motor 15 and a throttle position sensor 17 that detects a throttle position (throttle opening) are provided on the downstream side of the air flow meter 14 .

[0019] A surge tank 18 including an intake pressure sensor 19 is disposed downstream of the throttle valve 16 . The intake air pressure sensor 19 detects intake air pressure. Intake manifold 20 is connected to surge tank 18 . A fuel injector 21 is installed on each cylinder on the vicinity of the intake port so as to directly inject fuel into the cylinder. A spark plug 22 is installed on a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com