Preparation method for acrylic acid modified polyurethane water dispersion

A polyurethane water dispersion and polyurethane dispersion technology, which is applied in the field of acrylic modified polyurethane water dispersion for wood primer and its preparation, can solve the problem that the water resistance and sandability of the paint film are not good enough, the degree of crosslinking is not enough, and the PUA linear structure Branching and other problems, to achieve the effect of improving storage stability and improving hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

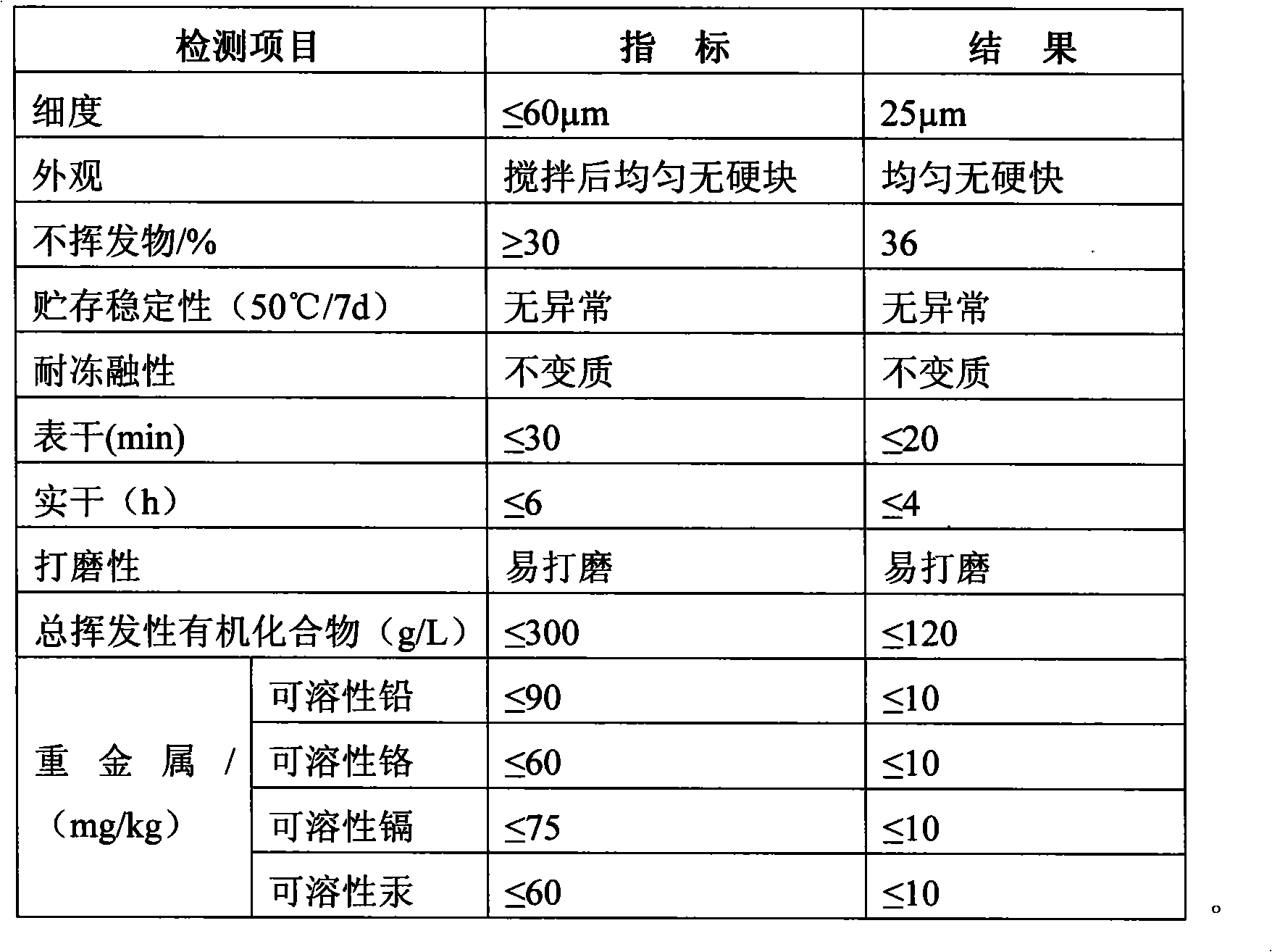

Examples

Embodiment 1

[0014] 3 parts of maleic anhydride, 30 parts of isophthalic acid, 15 parts of adipic acid, 35 parts of neopentyl glycol, 15 parts of propylene glycol, 0.5 parts of hydroquinone as a polymerization inhibitor, and the number average molecular weight is synthesized by solution polymerization method 1400-2000, polyester diol with a small amount of double bonds in the main chain.

[0015] First add 25 parts of dimethylol propionic acid (DMPA) to 22 parts of N-methylpyrrolidone, heat to dissolve, and mix 300 parts of polyester diol (H15) and 120 parts of toluene diisocyanate (TDI) at 80 React at ℃ for about 2 hours, then add the above-mentioned N-methylpyrrolidone solution of DMPA, continue the reaction until the isocyanate (NCO) reaches 0.63mmol / g, and add 0-100 parts of acetone to adjust the system depending on the increase in viscosity during the reaction Viscosity (guaranteed system viscosity ≤ 50s, cell test tube 25°C). Then lower the temperature to 50°C, add 15 parts of triet...

Embodiment 2

[0018] 1 part of maleic anhydride, 20 parts of isophthalic acid, 5 parts of adipic acid, 30 parts of neopentyl glycol, 10 parts of propylene glycol, 0.01 part of hydroquinone as a polymerization inhibitor, and the number average molecular weight is synthesized by solution polymerization method 1400-2000, polyester diol with a small amount of double bonds in the main chain.

[0019] First add 35 parts of dimethylol propionic acid (DMPA) to 20 parts of N-methylpyrrolidone, heat to dissolve, and mix 300 parts of polyester diol (H15) and 140 parts of toluene diisocyanate (TDI) at 80 React at ℃ for about 2 hours, then add the above-mentioned N-methylpyrrolidone solution of DMPA, continue the reaction until the isocyanate (NCO) reaches 0.71mmol / g, and add 0-100 parts of acetone to adjust the system depending on the increase in viscosity during the reaction Viscosity (guaranteed system viscosity ≤ 50s, cell test tube 25°C). Then lower the temperature to 50°C, add 21 parts of triethy...

Embodiment 3

[0022] 5 parts of maleic anhydride, 50 parts of isophthalic acid, 20 parts of adipic acid, 50 parts of neopentyl glycol, 20 parts of propylene glycol, 0.1 part of hydroquinone as a polymerization inhibitor, and the number average molecular weight was synthesized by solution polymerization method 1400-2000, polyester diol with a small amount of double bonds in the main chain.

[0023] First add 30 parts of dimethylol propionic acid (DMPA) to 25 parts of N-methylpyrrolidone, heat to dissolve, and mix 300 parts of polyester diol (H15) and 130 parts of toluene diisocyanate (TDI) at 80 React at ℃ for about 2 hours, then add the above-mentioned N-methylpyrrolidone solution of DMPA, continue the reaction until the isocyanate (NCO) reaches 0.67mmol / g, and add 0-100 parts of acetone to adjust the system depending on the increase in viscosity during the reaction Viscosity (guaranteed system viscosity ≤ 50s, cell test tube 25°C). Then lower the temperature to 50°C, add 18 parts of triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com