Preparation method for separating and purifying silicon dioxide and cerous chlorate from seeing stone waste material

A technology of silicon dioxide and cerous chloride, applied in the field of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

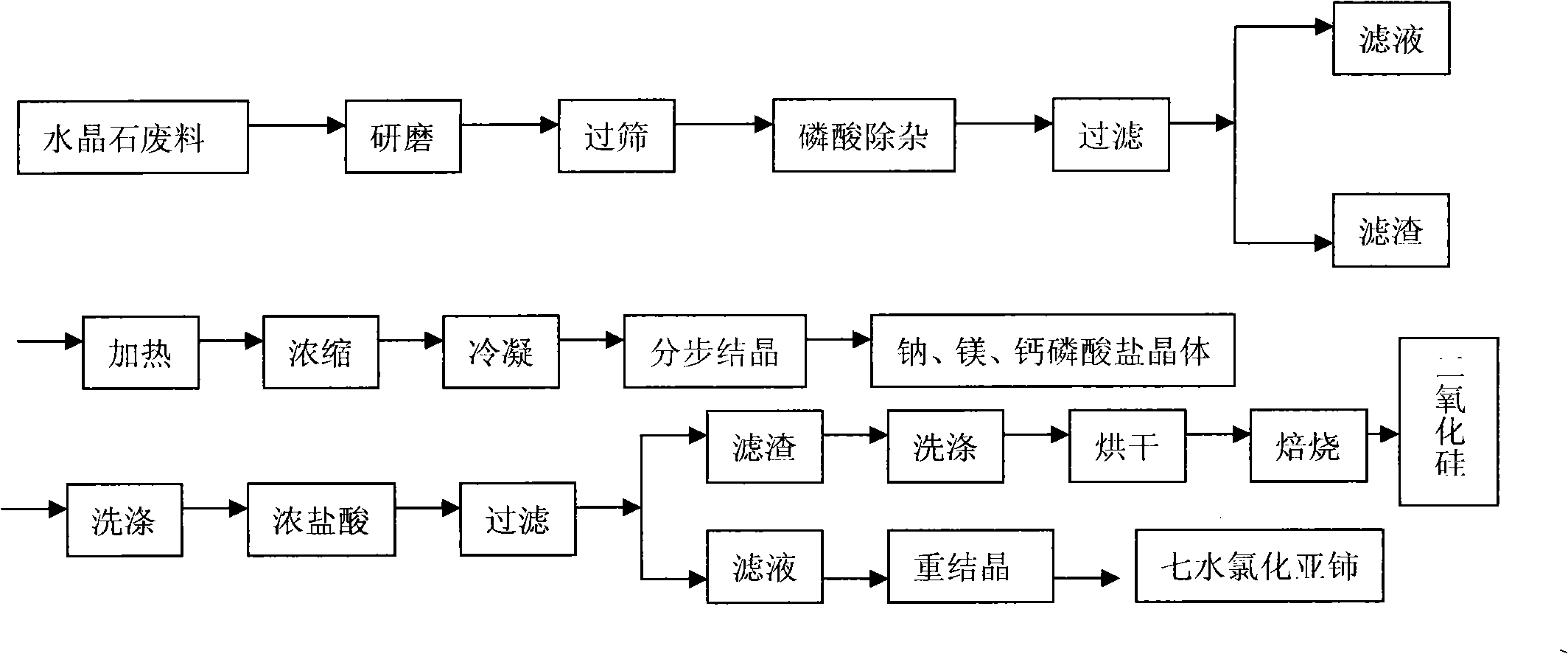

Image

Examples

Embodiment 1

[0021] At room temperature, a certain amount of crystal stone waste is weighed and passed through a 200-mesh sieve to obtain a raw material with a particle size of <75um. At room temperature, phosphoric acid with a concentration of 0.1 mol / L was selected as the impurity remover. Add phosphoric acid to 1 g of crystal stone waste, stir for 0.5 to 1.0 h, let stand, and filter. The filtrate is a mixed solution of Ca(H2PO4)2, Mg(H2PO4)2 and NaH2PO4. The filter residue is a mixed solid of silicon dioxide and cerium oxide. Add 50 mL of 12 mol / L concentrated hydrochloric acid to the mixed solid of silicon dioxide and cerium oxide, stir with a plastic rod in a water bath at 80°C and react for 2 hours until no pungent odor is produced. Filtration, the filter residue is silica solid, and the filtrate is cerium salt solution. The percentage of silicon dioxide is 93.44%, and the percentage of cerium is 92.50%. The reaction process of filtrate is as follows:

[0022] CaO+2H 3 PO 4 =Ca...

Embodiment 2

[0026] The mixed solid of silicon dioxide and cerium oxide obtained in Example 1 is washed until the washing water pH=6~8, and the temperature is controlled: <120° C. for drying; 50 mL of concentrated hydrochloric acid with a molar concentration of 12 mol / L is added as a separating agent to separate The reaction conditions are water bath at 60~100°C, the reaction time is 1~3h, filter, and the filtered filtrate is evaporated and crystallized at a temperature of <90°C until the crystals of cerous chloride heptahydrate are completely precipitated, and cerium oxide crystals are obtained after oxidation; The filter residue is dried at a temperature of <150° C. for 1 to 3 hours to obtain silicon dioxide with a percentage content of 96.38% and a percentage content of cerium of 97.55%. The reaction process of filtrate is as follows:

[0027] 2CeO 2 +8Hcl=2Cecl 3 +Cl 2 ↑+4H 2 o

Embodiment 3

[0029] Select the filter residue solid in Example 1 or 2, repeat the steps of Example 2 and Example 3 several times to obtain a silica solid, dry it at 150°C for 2h, and then roast it in a muffle furnace at 700°C for 0.5h to obtain the purity More than 99% precipitated silica products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com