Method for preparing biological active small peptide with endogenesis enzyme

A technology of biological activity and production process, applied in animal protein processing, animal feed, food science, etc., can solve the problems of high cost, long time for enzymatic hydrolysis of small peptides, and difficulty in industrialized large-scale production, so as to achieve cost saving and large-scale production. The effect of easy production and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

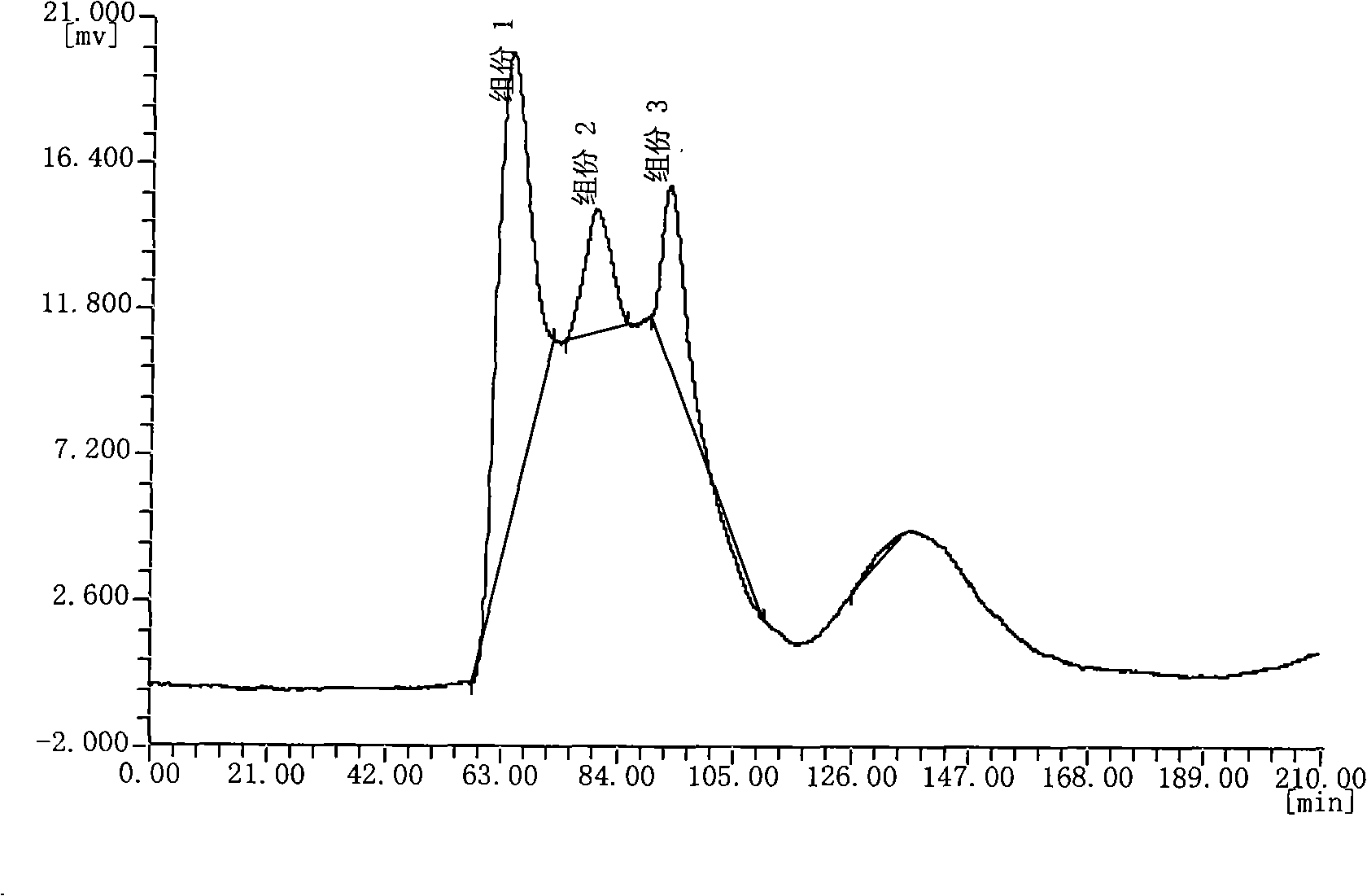

Image

Examples

Embodiment 1

[0028] Example 1. A production process for preparing biologically active small peptides with endogenous enzymes, the steps are as follows:

[0029] (1) Select marine low-value small miscellaneous fish or aquatic product processing scraps as raw materials. The raw materials are washed and crushed, and then water at 2°C is added to the raw materials at a weight ratio of 1:2 and put into a homogenizer or a homogenizer. Slurry in the middle to get fish paste material;

[0030] (2) Place the fish paste material in the enzymatic hydrolysis equipment, then add calcium chloride therein so that the concentration of the calcium chloride solution in the fish paste material is 0.02mol / L, and shake the fish paste material evenly under refrigeration; Then the fish paste material is heated up and the temperature is controlled at 53°C, the pH is adjusted to 6.8 with a hydrochloric acid solution with a concentration of 1.0mol / L and a sodium hydroxide solution with a concentration of 1.0mol / L,...

Embodiment 2

[0032] Example 2. A production process for preparing biologically active small peptides with endogenous enzymes, the steps are as follows:

[0033] (1) Select marine low-value small miscellaneous fish or aquatic product processing scraps as raw materials. The raw materials are washed and crushed, and then water at 6°C is added to the raw materials at a weight ratio of 1:3 and put into a homogenizer or a homogenizer. Slurry in the middle to get fish paste material;

[0034] (2) Place the fish paste material in the enzymatic hydrolysis equipment, then add calcium chloride therein so that the concentration of the calcium chloride solution in the fish paste material is 0.03mol / L, and shake the fish paste material evenly under refrigeration; Then the fish paste material is heated up and the temperature is controlled at 57°C, the pH is adjusted to 7.2 with a hydrochloric acid solution with a concentration of 2.0mol / L and a sodium hydroxide solution with a concentration of 2.0mol / L,...

Embodiment 3

[0036] Example 3. A production process for preparing biologically active small peptides with endogenous enzymes, the steps are as follows:

[0037] (1) Select marine low-value small miscellaneous fish or aquatic product processing waste as raw materials. The raw materials are washed and crushed, and then water at 4°C is added to the raw materials at a weight ratio of 1:2.5 and put into a homogenizer or a homogenizer. Slurry in the middle to get fish paste material;

[0038] (2) The fish paste material is placed in the enzymatic hydrolysis equipment, and then calcium chloride is added therein so that the concentration of the calcium chloride solution in the fish paste material is 0.025mol / L, and the fish paste material is shaken evenly under refrigeration; Then the fish paste material is heated up and the temperature is controlled at 55°C, the pH is adjusted to 7 with a hydrochloric acid solution with a concentration of 1.5mol / L and a sodium hydroxide solution with a concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com