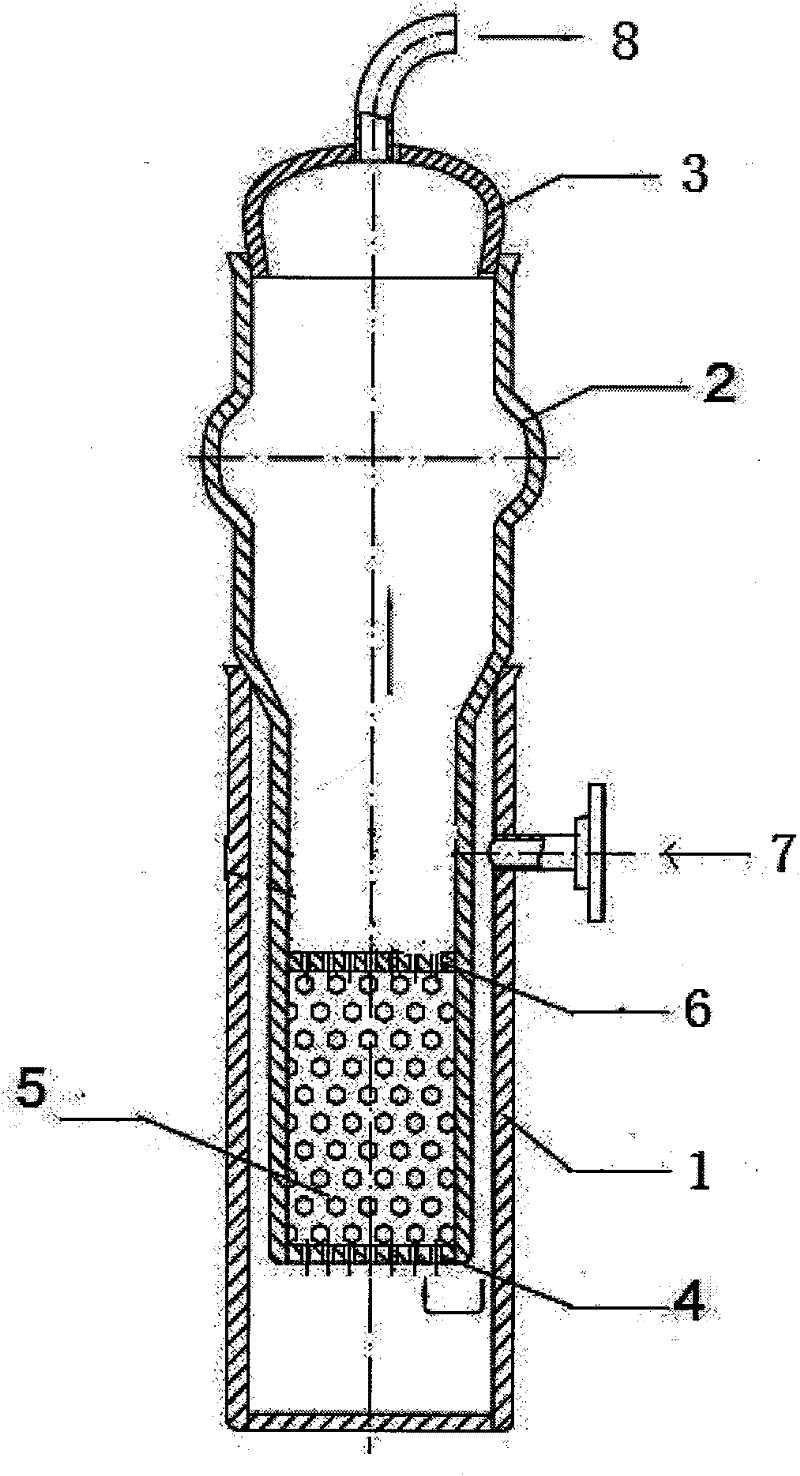

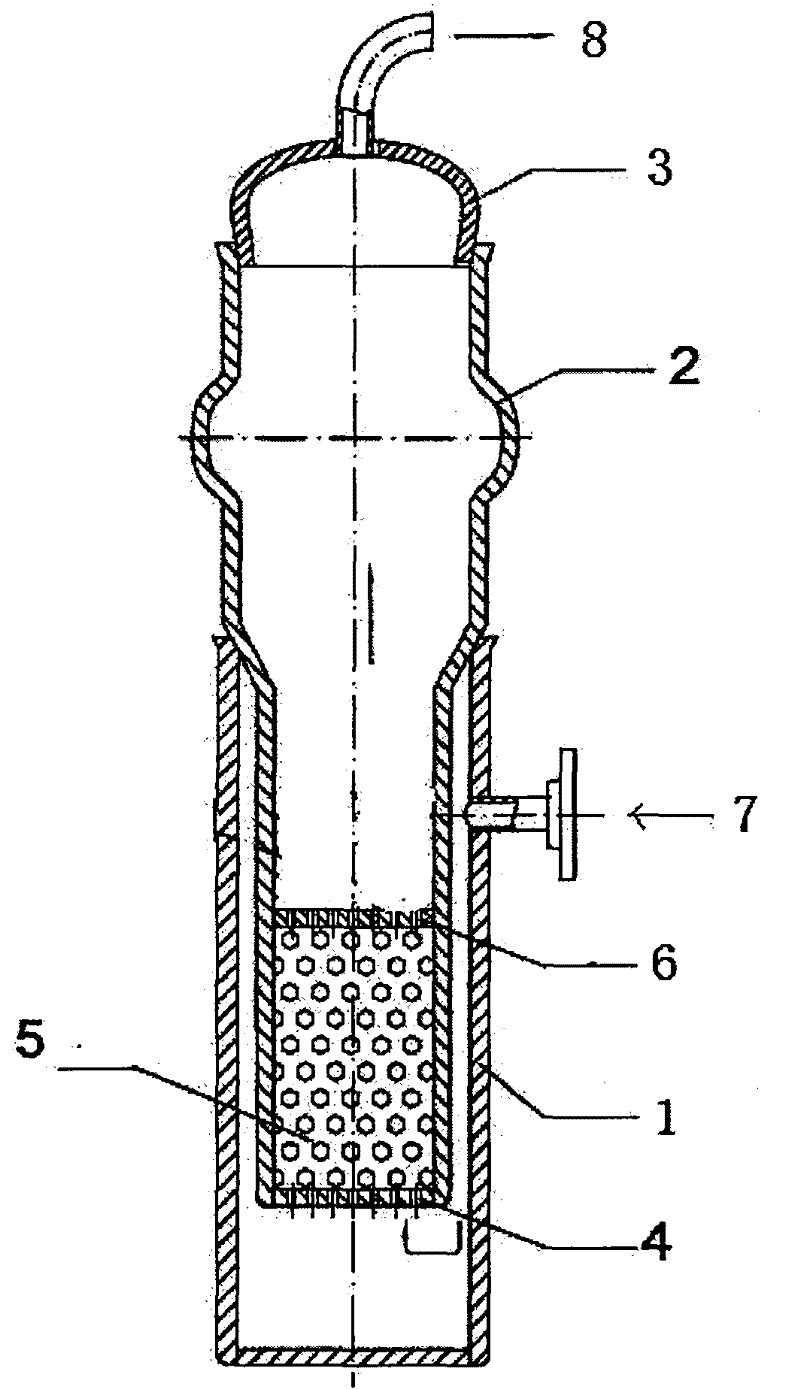

Flue gas trapping and absorption apparatus and its uses in cigarette flue gas heavy metal element determination

An absorption device and flue gas capture technology, which is applied in the direction of measuring devices, sampling devices, instruments, etc., can solve the problems of inability to fully reflect the heavy metal content of flue gas, and achieve low detection limit, increased surface area, and high detection sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

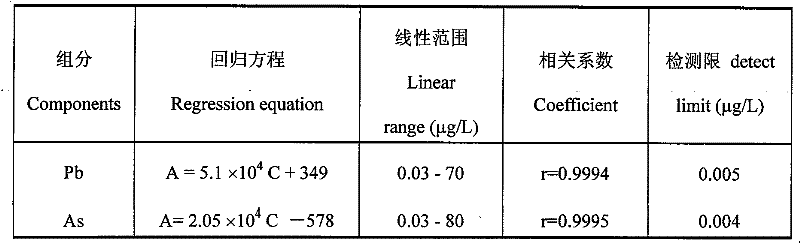

Embodiment 1

[0031] Take one cigarette sample of a certain brand, balance it under the conditions specified in the GB / T 16447 standard, and select cigarettes with an average weight of ±0.02g and an average draw resistance of ±49Pa as test cigarettes; seal the cigarettes in the smoke trap On the suction port machine of the absorber, under the conditions specified in the YC / T 29 standard, use a smoking machine to suck from the exhaust port of the smoke collecting absorber. The suction capacity of each port is 35.0±0.3mL, and the suction time is 2± 0.1s, the puffing interval is 30±s, and 20 cigarettes are puffed each time; 35ml of 5% nitric acid is used as the trapping agent for the flue gas; Pour out the trapping liquid, and ultrasonically clean the absorber with 7.0mL of 5% nitric acid twice, combine the solution and the trapping liquid, and then set the volume to 50mL; at the same time, make a control blank sample according to the conventional process. The results of the determination of h...

Embodiment 2

[0035] Take one cigarette sample of a certain foreign brand, balance it under the conditions specified in GB / T 16447, select the cigarettes with an average weight of ±0.02g and an average draw resistance of ±49Pa as the test cigarettes; seal the cigarettes in the smoke On the suction port of the trapping absorber, under the conditions specified in the YC / T 29 standard, use a smoking machine to suck from the exhaust port of the flue gas trapping absorber. The suction capacity of each port is 35.0±0.3mL, and the suction time is 2 ±0.1s, the puffing interval is 30±s, 20 cigarettes are puffed each time; 35ml of 5% nitric acid is used as the trapping agent for the flue gas; Pour out the trapping solution, clean the absorber twice with 7.0mL of 5% nitric acid ultrasonically, combine the solution and the trapping solution, and then set the volume to 50mL; at the same time, make a control blank sample according to the conventional process. The results of the determination of heavy met...

Embodiment 3

[0039] Take one cigarette sample of a certain brand, balance it under the conditions specified in the GB / T 16447 standard, and select cigarettes with an average weight of ±0.02g and an average draw resistance of ±49Pa as test cigarettes; seal the cigarettes in the smoke trap On the suction port machine of the absorber, under the conditions specified in the YC / T 29 standard, use a smoking machine to suck from the exhaust port of the smoke collecting absorber. The suction capacity of each port is 35.0±0.3mL, and the suction time is 2± 0.1s, the puffing interval is 30±s, and 20 cigarettes are puffed each time; 35ml of 5% nitric acid is used as the trapping agent for the flue gas; Pour out the trapping liquid, and ultrasonically clean the absorber with 7.0mL of 5% nitric acid twice, combine the solution and the trapping liquid, and then set the volume to 50mL; at the same time, make a control blank sample according to the conventional process. The results of the determination of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com