Organic-inorganic composite flame retardants with mesoporous molecular sieve and method for preparing same

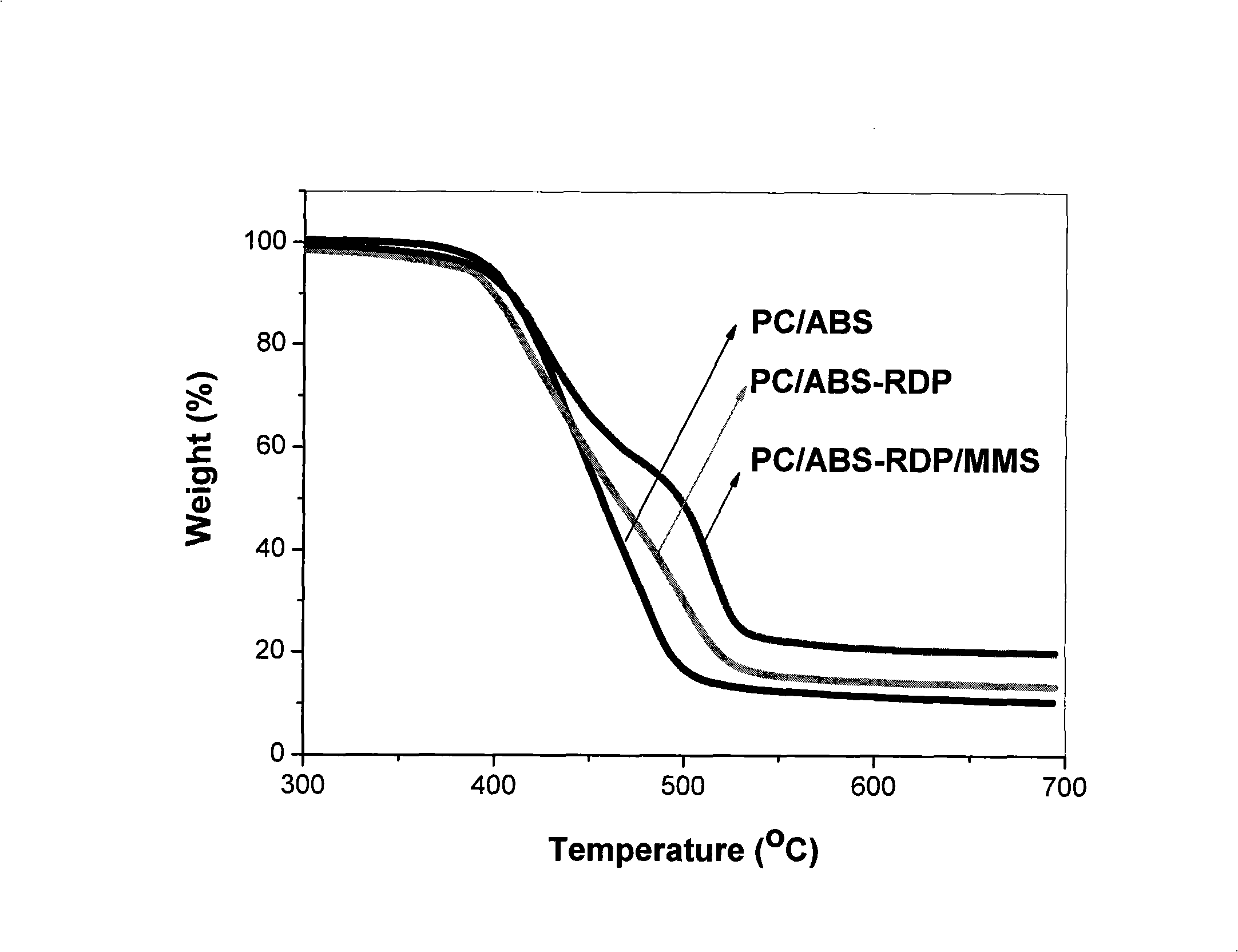

A mesoporous molecular sieve and inorganic composite technology, which is applied in the polymer field to achieve the effects of improving thermal stability, preventing the migration of flame retardants, and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

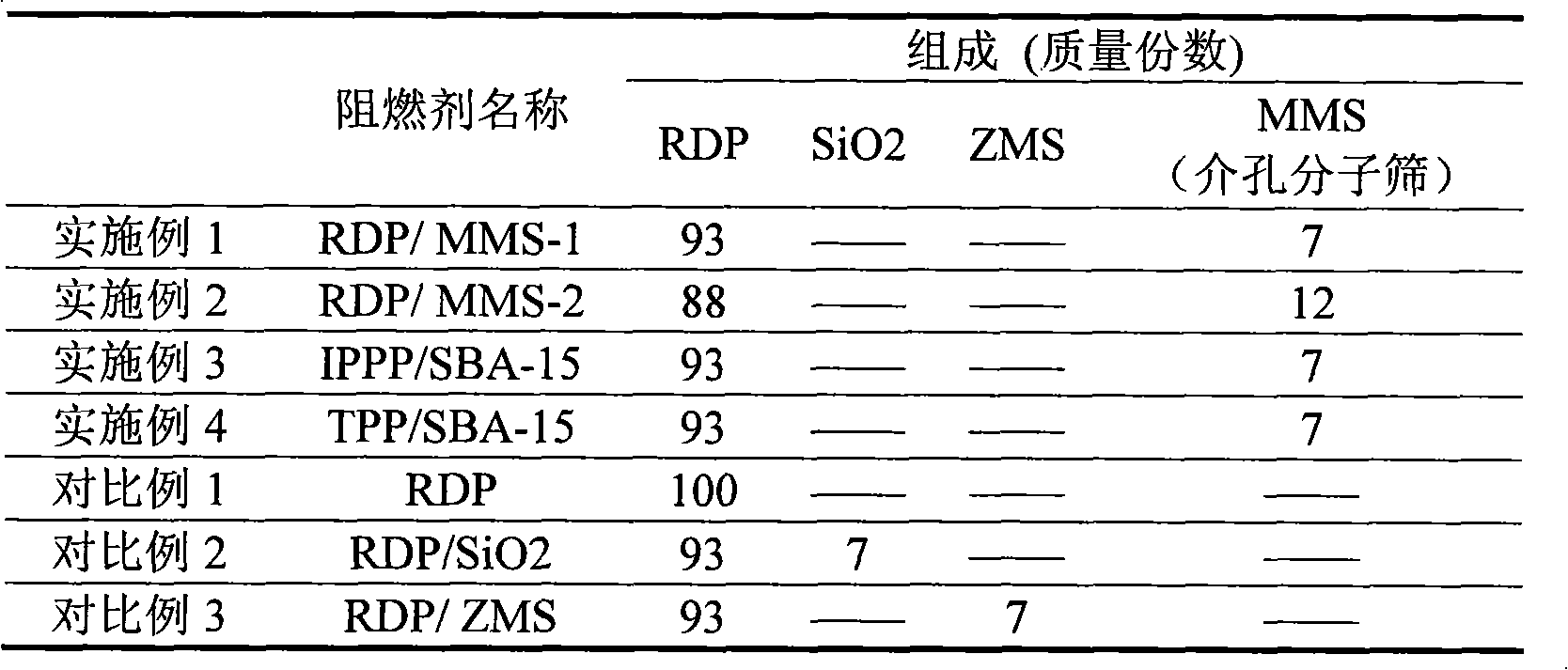

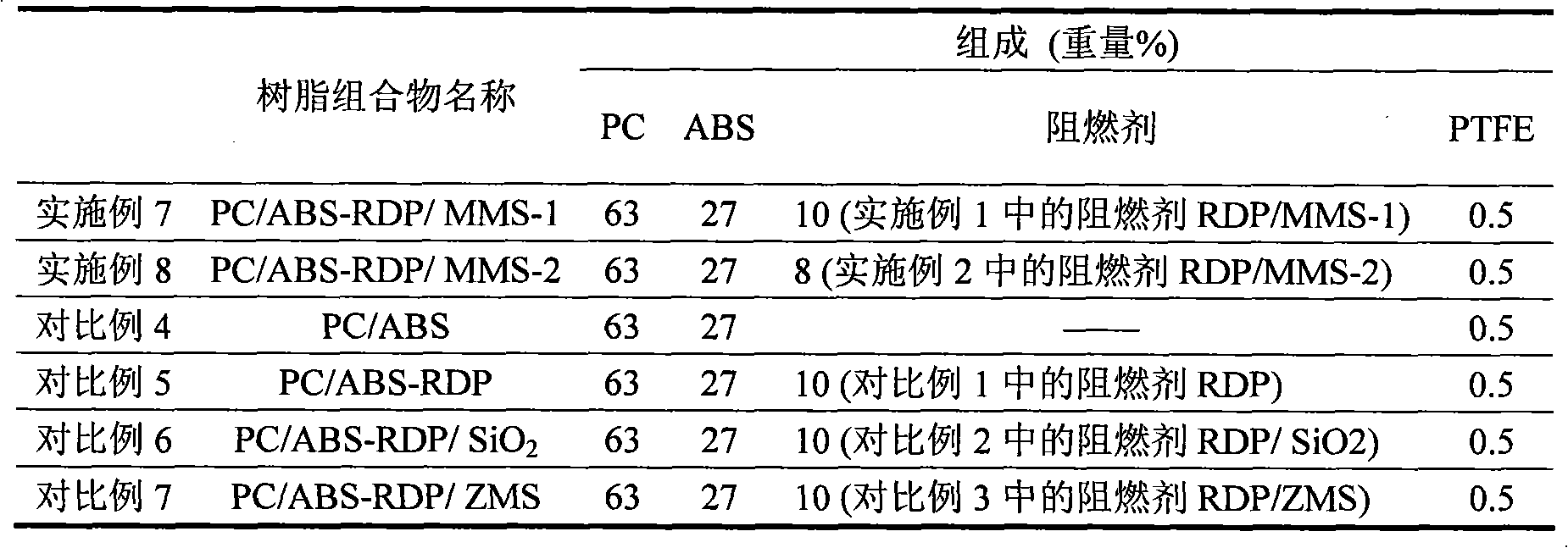

Embodiment 1

[0067] Drying of mesoporous molecular sieves: Dry 21g of MCM-41 mesoporous molecular sieves at 250°C for 2 hours under a vacuum condition with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0068] Flame retardant pretreatment: Thin the viscosity of 279g liquid RDP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0069] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated RDP flame retardant liquid into the dried MCM-41 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 100°C for 3 hours, and at room temperature for 20 hours;

[0070] Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was ultrasonically oscillated at a frequency of 59kHz for 1h, ...

Embodiment 2

[0072] Drying of mesoporous molecular sieves: Dry 36g of MCM-41 mesoporous molecular sieves at 250°C for 2 hours under vacuum conditions with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0073] Flame retardant pretreatment: Thin the viscosity of 264g liquid RDP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0074] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated RDP flame retardant liquid into the dried MCM-41 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 100°C for 3 hours, and at room temperature for 20 hours;

[0075]Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was ultrasonically oscillated at a frequency of 59kHz for 1h, an...

Embodiment 3

[0077] Drying of mesoporous molecular sieves: Dry 21g of SBA-15 mesoporous molecular sieves at 220°C for 5 hours under vacuum conditions with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0078] Flame retardant pretreatment: Thin the viscosity of 279g of liquid IPPP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0079] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated IPPP flame retardant liquid into the dried SBA-15 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 90°C for 2 hours, and at room temperature for 25 hours;

[0080] Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was oscillated with ultrasonic waves at a frequency of 100k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com