Sewage disposal and circling reclamation method

A recycling and sewage treatment technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that aerobic microbial treatment capacity cannot be fully utilized and cannot be kept in a constant state. Aerobic state, low concentration of aerobic microorganisms, etc., to achieve the effect of solving the problem of reduction, reducing emissions, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

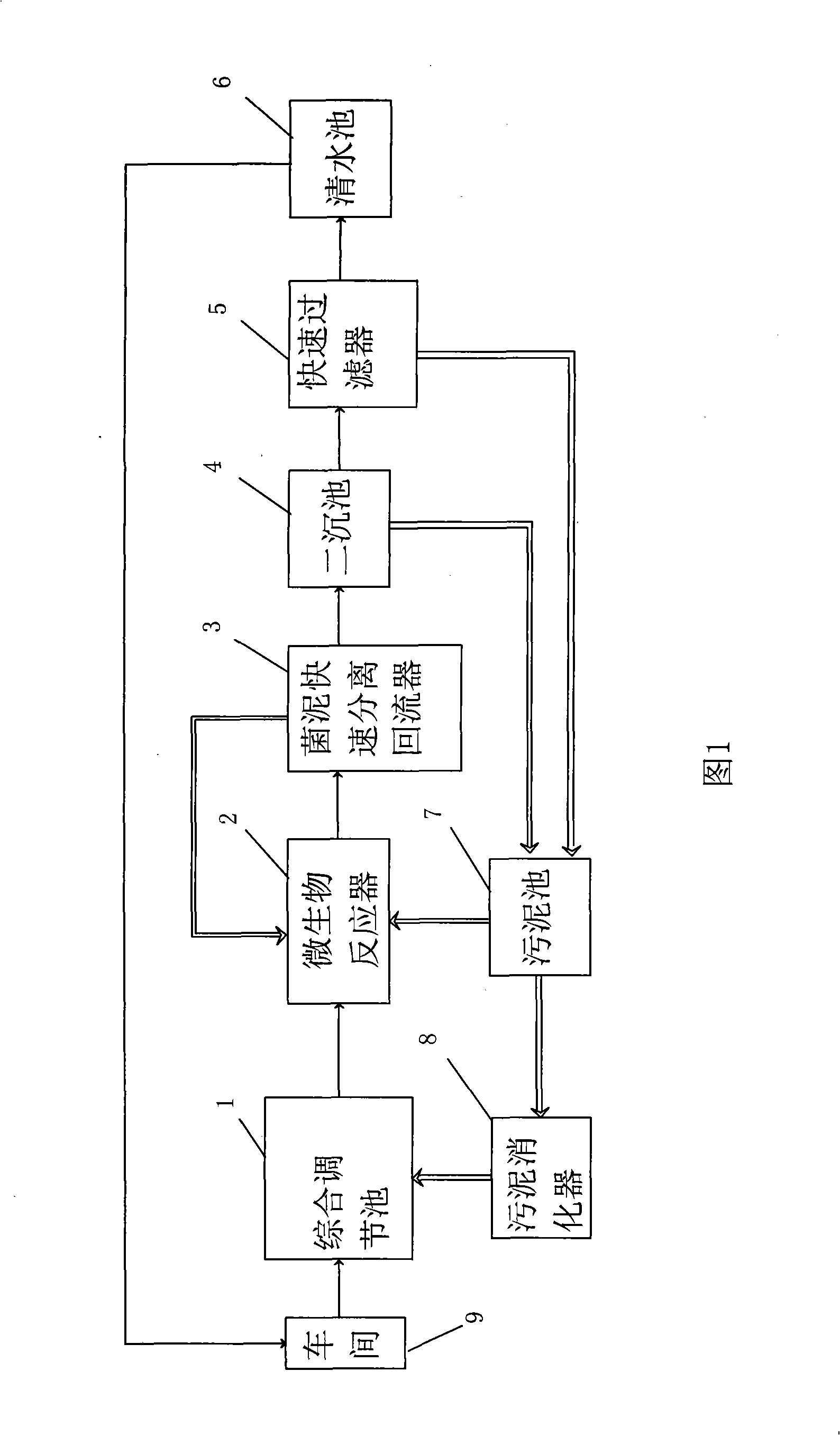

[0017] As shown in Figure 1, the method of sewage treatment and recycling includes a comprehensive adjustment tank 1, a microbial reactor 2, a rapid separation reflux device for bacteria sludge 3, a secondary settling tank 4, a sludge tank 7, and a sludge digester 8. 8 main structural units such as filter 5 and clear water pool 6. Anaerobic bacteria are cultivated in the comprehensive regulation pool 1. A packing frame is arranged in the microbial reactor 2, and the packing with aerobic bacteria is fixed on the packing frame. Filler with anaerobic bacteria is added to the sludge digester 8 accounting for 50% of the tank volume.

[0018] The sewage is silk-making wastewater. The sewage first enters the comprehensive adjustment tank 1, and reacts with the anaerobic bacteria group in the comprehensive adjustment tank 1 to eliminate part of the organic matter. The sewage stays in the comprehensive adjustment tank 1 for 3 hours, and its supernatant enters the microbial reaction D...

Embodiment 2

[0024] As shown in Figure 1, the method of sewage treatment and recycling includes a comprehensive adjustment tank 1, a microbial reactor 2, a rapid separation reflux device for bacteria sludge 3, a secondary settling tank 4, a sludge tank 7, and a sludge digester 8. 8 main structural units such as filter 5 and clear water pool 6. The anaerobic bacteria are cultivated in the comprehensive adjustment pool 1. A packing frame is arranged in the microbial reactor 2, and the packing with aerobic bacteria is fixed on the packing frame. Filler with anaerobic bacteria is added to the sludge digester 8 accounting for 50% of the tank volume.

[0025] The sewage is recycled papermaking wastewater. The sewage first enters the comprehensive adjustment tank 1, and reacts with the anaerobic bacteria group in the comprehensive adjustment tank 1 to eliminate part of the organic matter. The sewage stays in the comprehensive adjustment tank 1 for 10 hours, and its supernatant enters the microbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com