Bakelite structural optic cable and cable delivery hank and preparation thereof

A technology of structured light and delivery trays, which is applied in the direction of flat products, manufacturing tools, wood processing equipment, etc., and can solve the problems of increasing wood and steel consumption, complex processes, and easily damaged optical cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

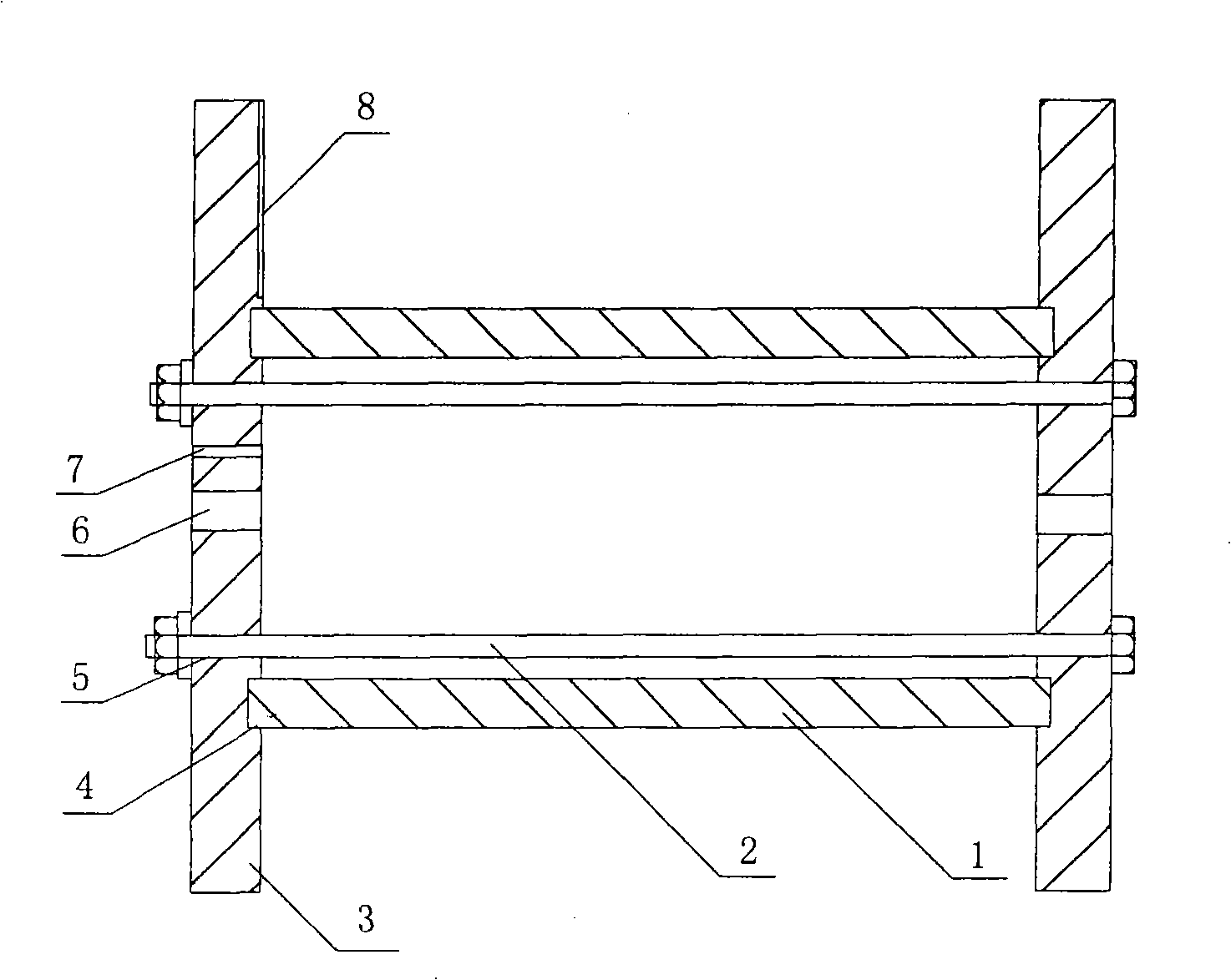

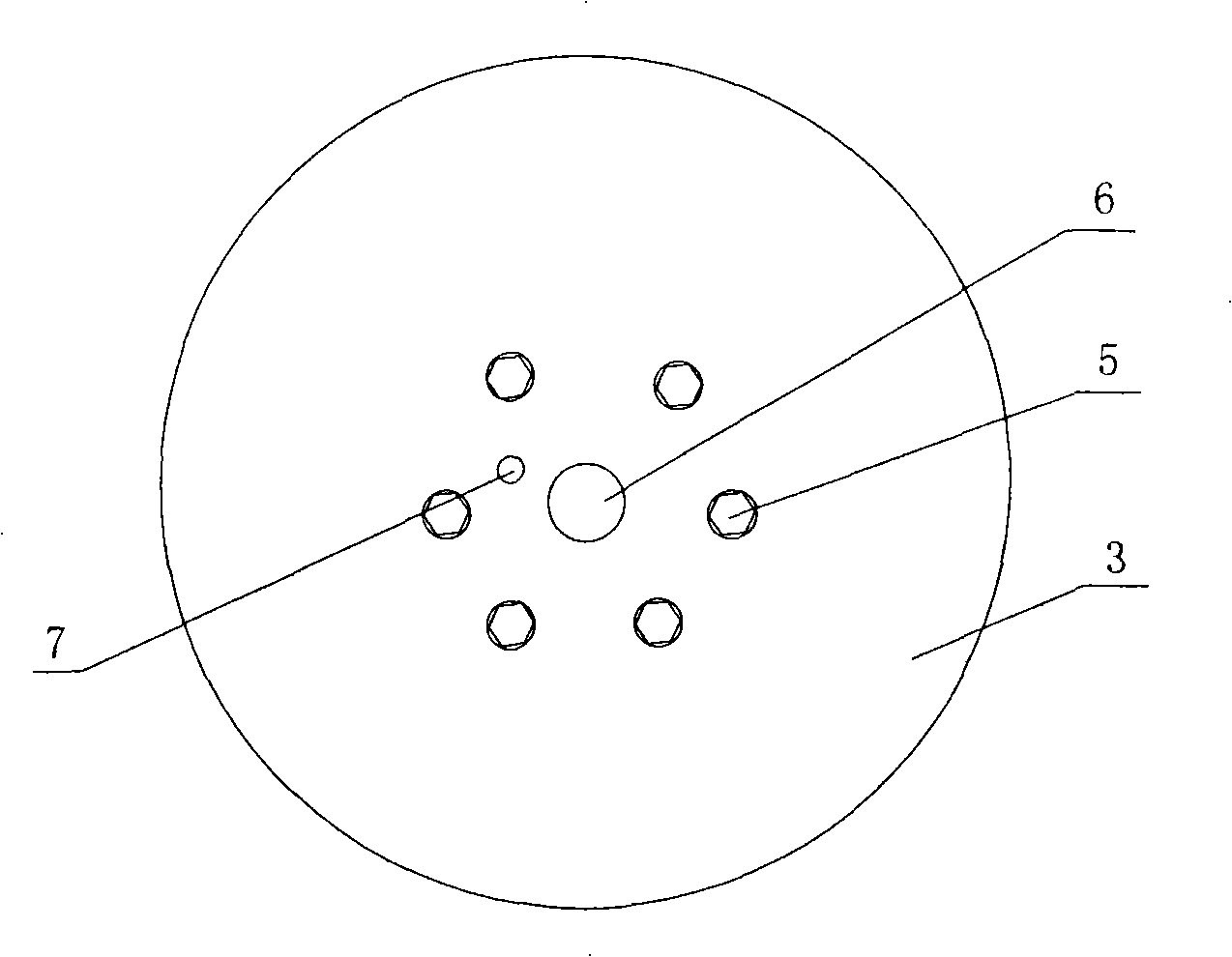

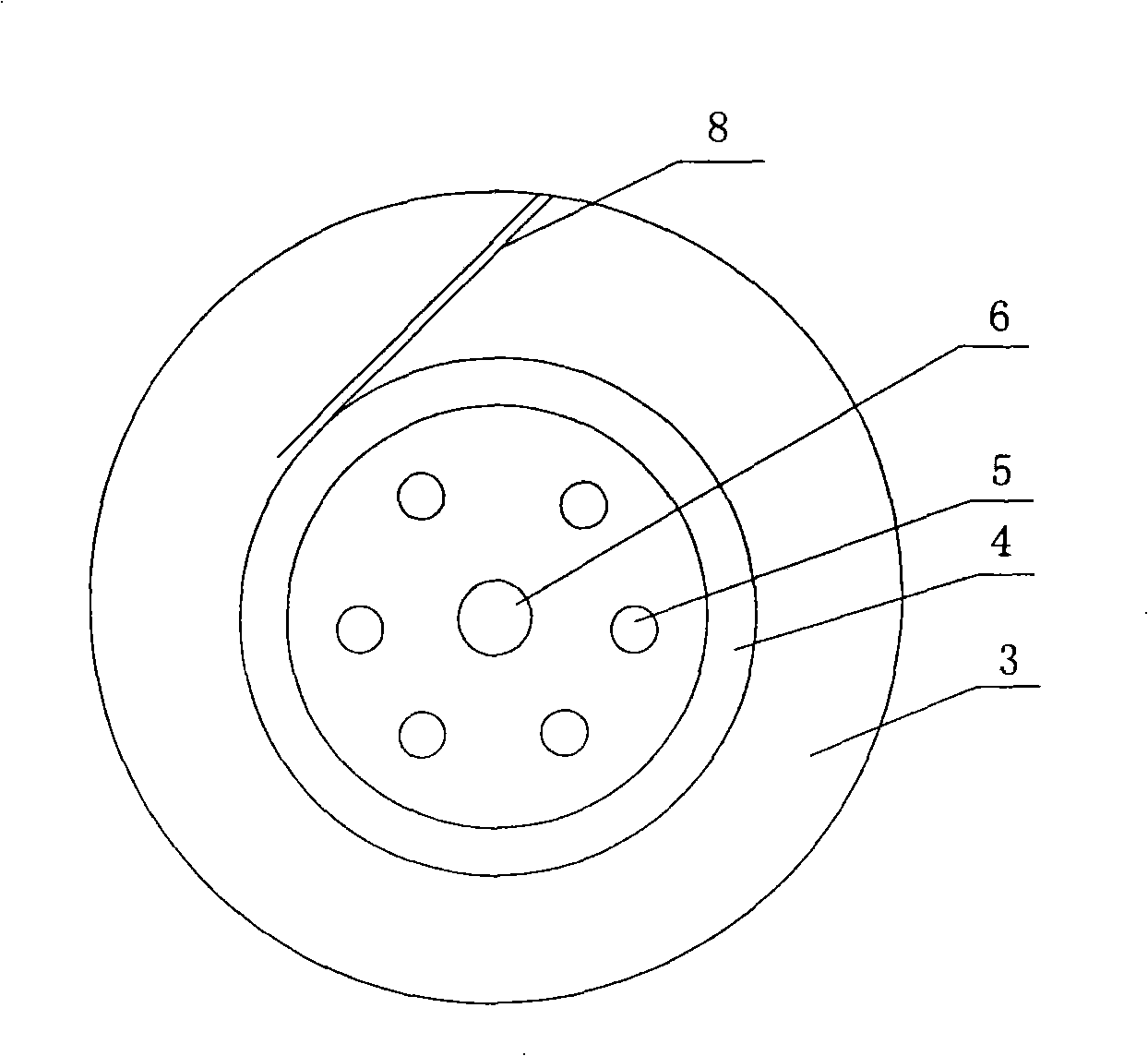

[0026] 1. Disc production:

[0027] Disc 3 is crushed with wood scraps from wood processing plants or agricultural and forestry tree pruning scraps, stirred with waterproof glue, put into a mold, and pressed by a pressing machine. The inner surface of the side plate of the disc and the outer surface of the cylinder must be smooth and flat. Production method: crush wood scraps from wood processing factories or agricultural and forestry tree pruning scraps into chunks with a length of 30-40mm and a diameter of 1-2mm. Dry the chunks at a drying temperature of 30°C. Put the dried material block and waterproof glue into the mixer and stir evenly. The weight ratio of material block and waterproof glue is 4:1. Put the mixture of material block and waterproof glue into the disc mold installed in the press, and use the press machine Press into platters. The mold is made according to the size of the tray with various specifications. The pressing temperature is 130°C and the pressing ti...

Embodiment 2

[0038] 1. Disc production:

[0039] Disc 3 is crushed with wood scraps from wood processing plants or agricultural and forestry tree pruning scraps, stirred with waterproof glue, put into a mold, and pressed by a pressing machine. The inner surface of the side plate of the disc and the outer surface of the cylinder must be smooth and flat. Production method: crush the wood scraps from the wood processing factory or the agricultural and forestry tree pruning scraps into blocks, the length of the blocks is 30-40mm, and the diameter is 1-2mm. Dry the blocks at a drying temperature of 45°C. Put the dried material block and waterproof glue into the mixer and stir evenly. The weight ratio of material block and waterproof glue is 4:1. Put the mixture of material block and waterproof glue into the disc mold installed in the press, and use the press machine Press into platters. The mold is made according to the size of the tray with various specifications. The pressing temperature is ...

Embodiment 3

[0050] 1. Disc production:

[0051] Disc 3 is crushed with wood scraps from wood processing plants or agricultural and forestry tree pruning scraps, stirred with waterproof glue, put into a mold, and pressed by a pressing machine. The inner surface of the side plate of the disc and the outer surface of the cylinder must be smooth and flat. Production method: crush wood scraps from wood processing factories or agricultural and forestry tree pruning scraps into chunks with a length of 30-40mm and a diameter of 1-2mm. Dry the chunks at a drying temperature of 50°C. Put the dried material block and waterproof glue into the mixer and stir evenly. The weight ratio of material block and waterproof glue is 4:1. Put the mixture of material block and waterproof glue into the disc mold installed in the press, and use the press machine Press into platters. The mold is made according to the size of the tray with various specifications. The pressing temperature is 140°C and the pressing ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com