Compound nut

A nut and compound technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of inability to prevent loosening, unsuitable fastening, and large thread damage, etc., and achieve the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

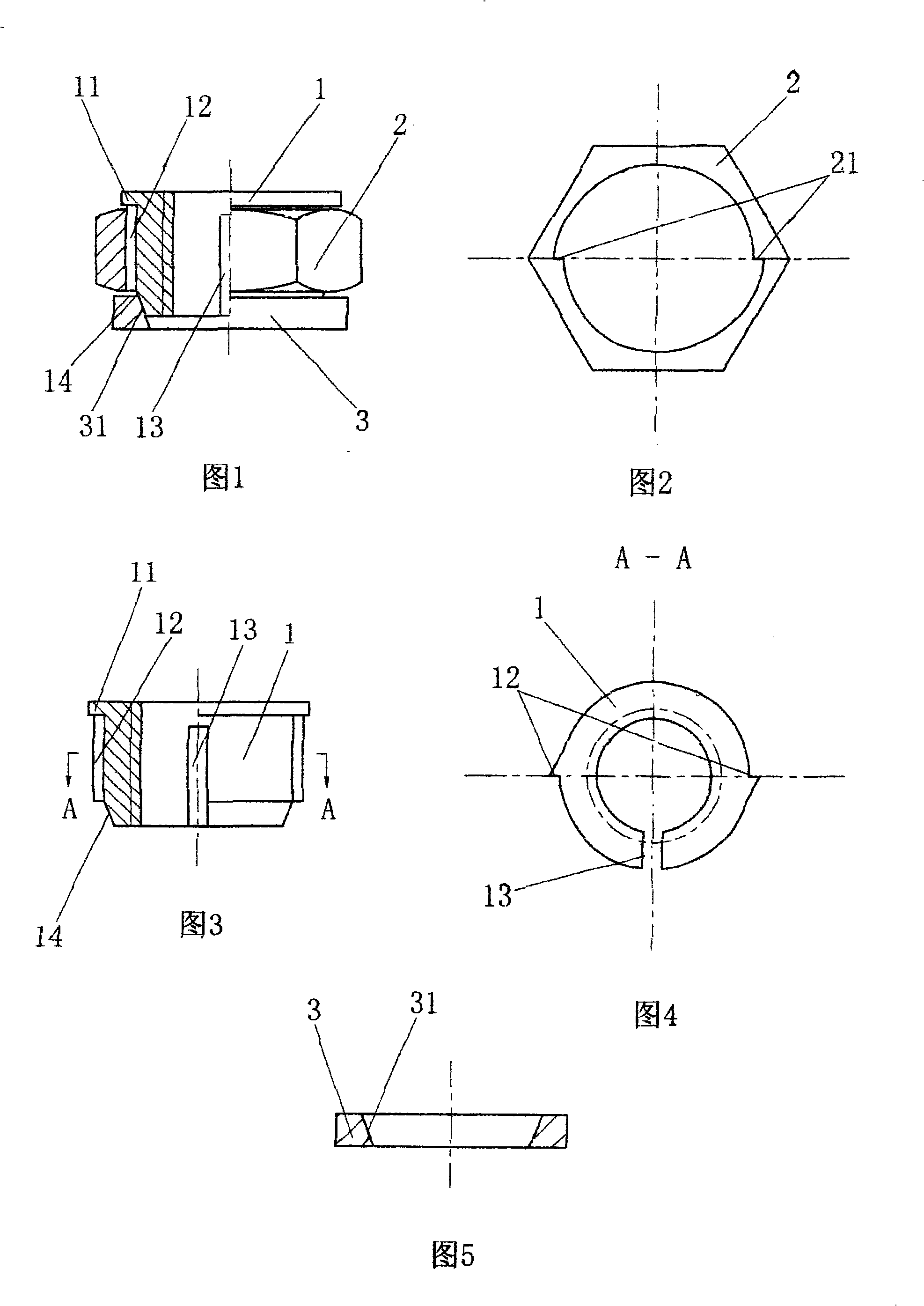

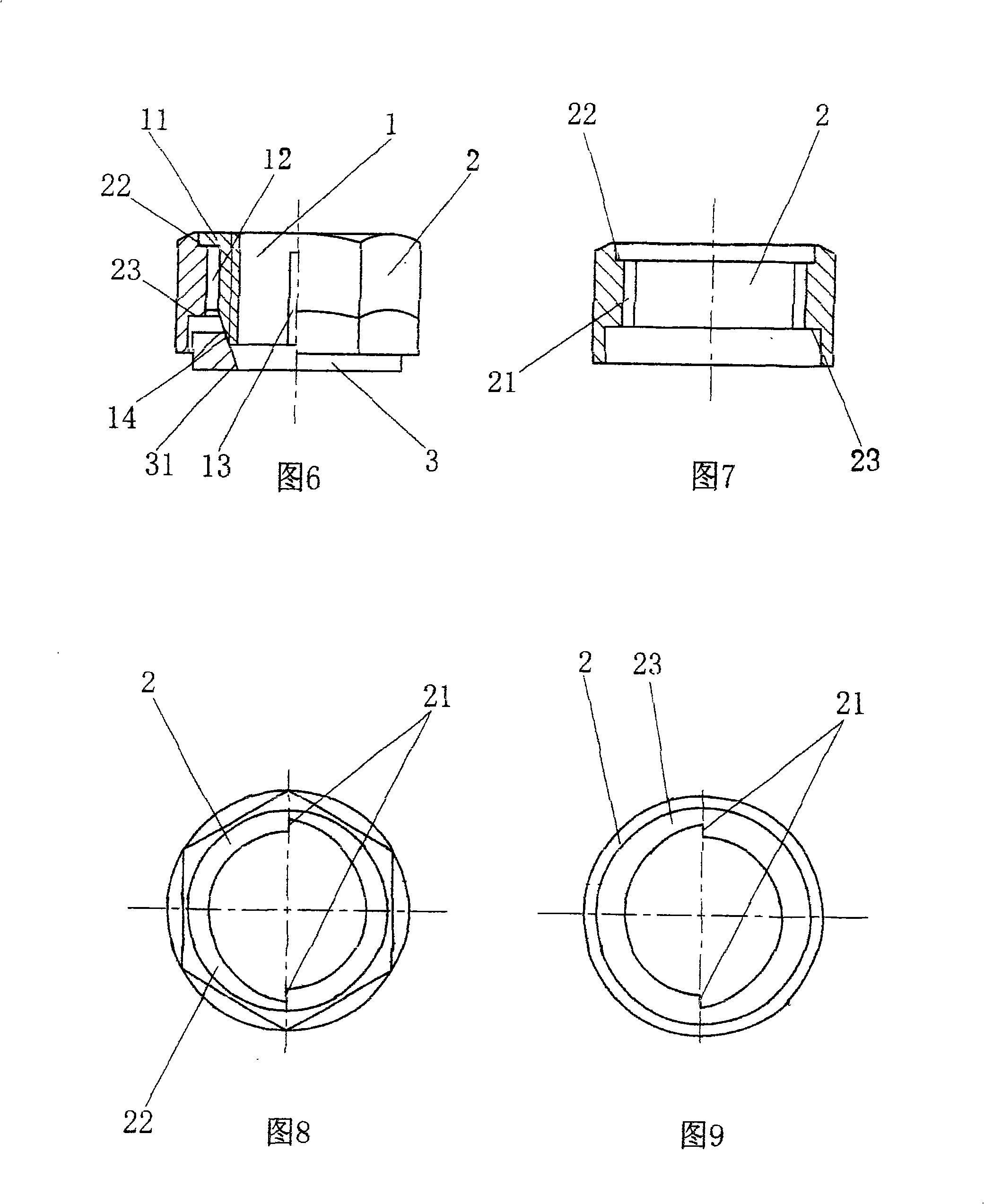

[0018] As shown in Figures 1 to 5, the specific embodiment of the present invention is a compound nut, which includes a nut body (1) and an outer casing (2). The nut body (1) is provided with a through internal thread, and the nut body (1) ) is provided with a shoulder (11) on the outer diameter of the upper end, the outer diameter of the shoulder (11) is larger than the inner diameter of the jacket (2), and the joint between the nut body (1) and the jacket (2) is provided with a ratchet mechanism for one-way engagement The ratchet mechanism consists of two ratchets (12) arranged on the outer diameter of the nut body (1) and two ratchets (21) arranged on the inner diameter of the outer casing (2). The end is provided with a slot (13) in the axial direction, and the axial height of the slot (13) is less than the height of the nut body (1), that is, the slot (13) is not cut to the bottom in the axial direction, and the nut body (1 ) is provided with an outer cone (14) on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com