High performance wiping fabric and manufacturing method thereof

A high-performance, fabric technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of lack of compactness, impact on wiping performance, soft hand feeling of wiping cloth, etc., and achieve good wiping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

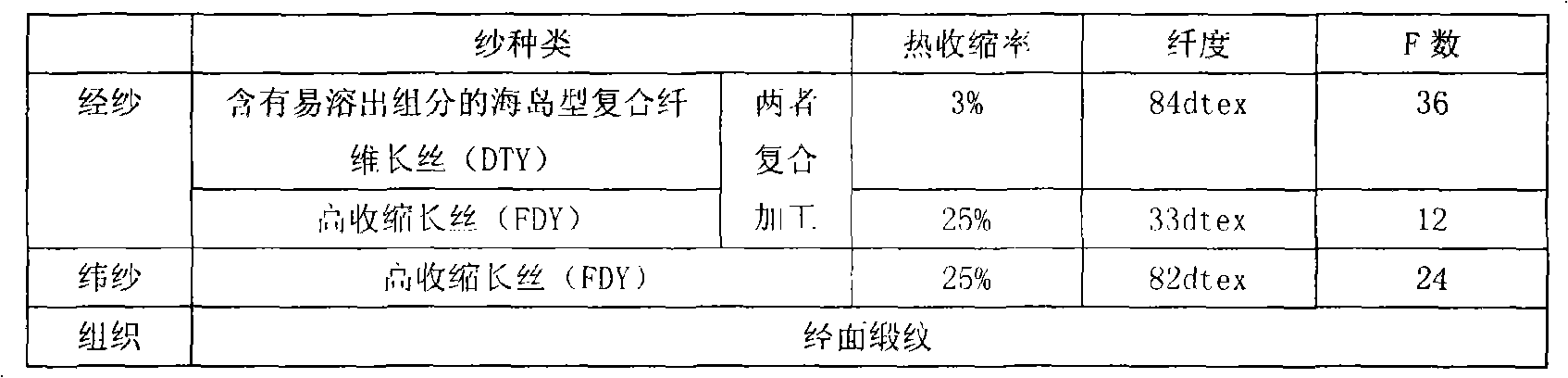

[0018] The present embodiment selects the long filament and tissue weaving of following table 1 for use:

[0019] Table 1

[0020]

[0021] Select sea-island type composite fiber filament (DTY) and high-shrinkage filament (FDY) composite processing yarn containing easily eluted components as warp yarn, high-shrinkage filament (FDY) as weft yarn, the gray fabric after weaving is refined, and then Treatment at 80-130°C for 1-2 hours, including reducing the amount of sea-island composite filament fibers containing easily soluble components (controlling the reduction rate to 30%), and then passing through the strong water flow in the liquid flow refining machine The method of impact fiber opening is to open fiber of the fabric, heat setting at 150 ℃, and the finished product is obtained, the weight is 220g / m 2 about. Satin front is wipe side. After the above treatment, the finished ultra-fine long fibers are fully opened and become compact and thick, and the ultra-fine long ...

Embodiment 2

[0023] Example 2:

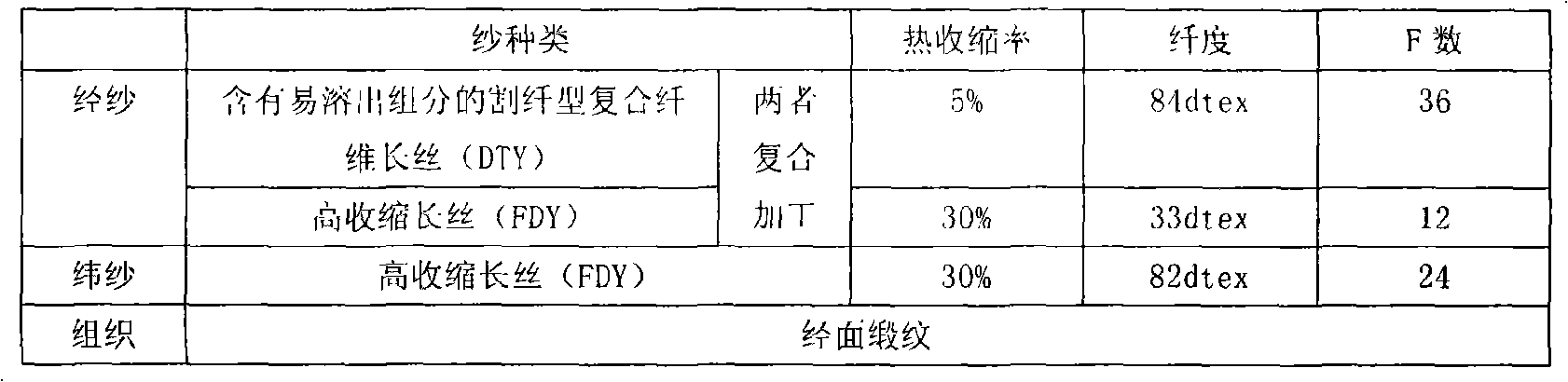

[0024] The present embodiment selects the long filament and tissue weaving of following table 2 for use:

[0025] Table 2

[0026]

[0027] Select the composite processing yarn of cut-fiber composite fiber filament (DTY) and high-shrinkage filament (FDY) containing easily soluble components as the warp yarn, and high-shrinkage filament (FDY) as the weft yarn. The gray fabric after weaving is scoured and then Treat for 1-2 hours under the condition of 80-130°C, which includes carrying out decrement processing (controlling the decrement rate to 20%) and then impacting the fiber-opening method with high-pressure airflow on the split-fiber composite filament fibers containing easily soluble components. Fabric opening treatment, heat setting at 150°C, and finished product with a grammage of 230g / m 2 about. Satin front is wipe side. After the above treatment, the finished ultra-fine long fibers are fully opened and become compact and thick, and the ultra-f...

Embodiment 3

[0029] In this embodiment, the composite processing yarn of superfine polyester filament (single filament fineness: 0.01-1.2Den) obtained directly after spinning and high-shrinkage filament (FDY) is selected as the warp and weft yarn, and in the process of processing Embrittlement and alkali reduction treatment are not required, and the fiber opening method of physical kneading is adopted. The weight of the finished product after processing is 240g / m 2 The rest are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com