Numerical control selected area electrochemical deposition rapid forming method and apparatus

A molding method and electrochemical technology, applied in electroforming, electrolytic process, 3D structure electroforming, etc., can solve problems such as restricting the development of electroforming technology, and achieve the effect of broadening the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

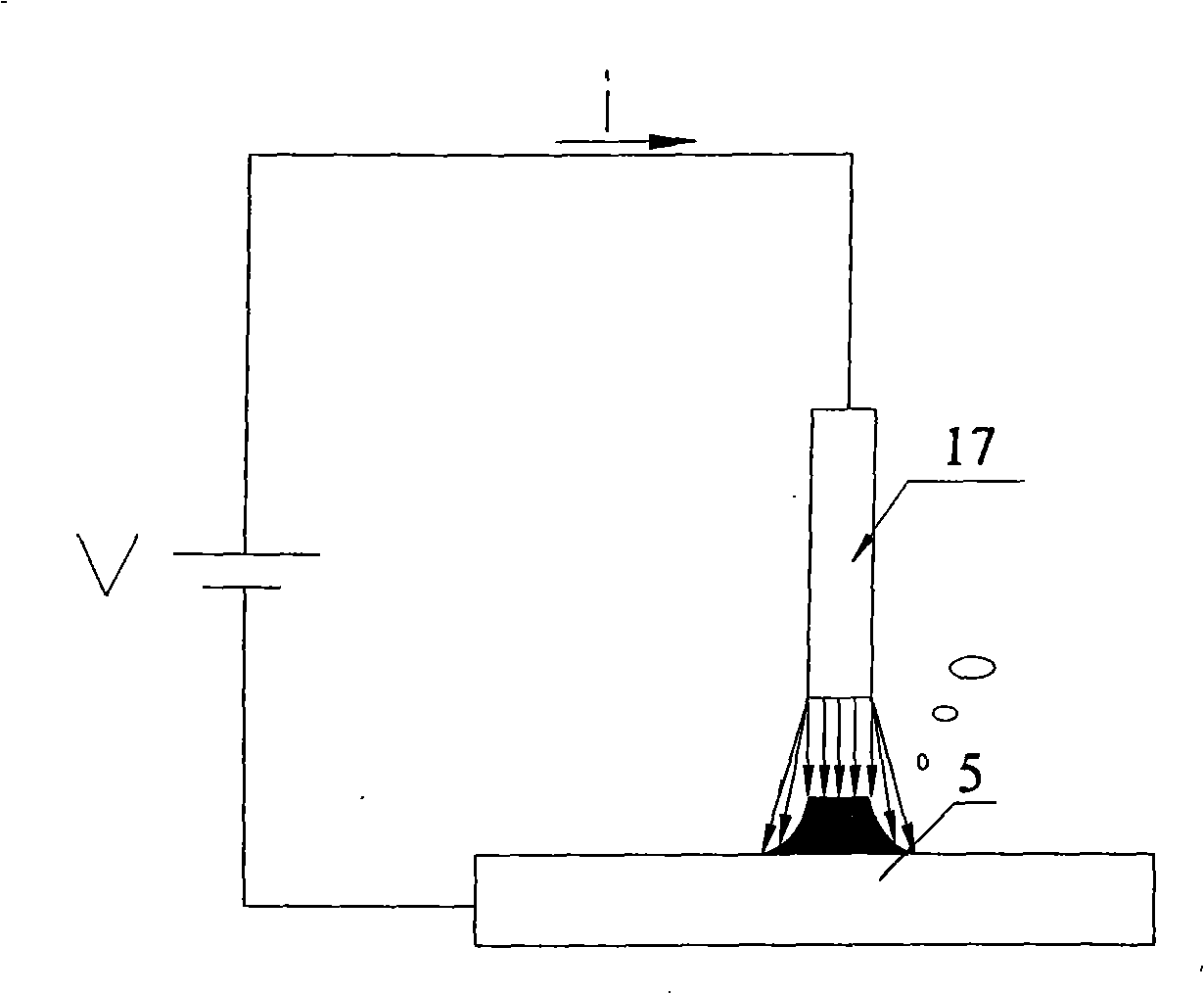

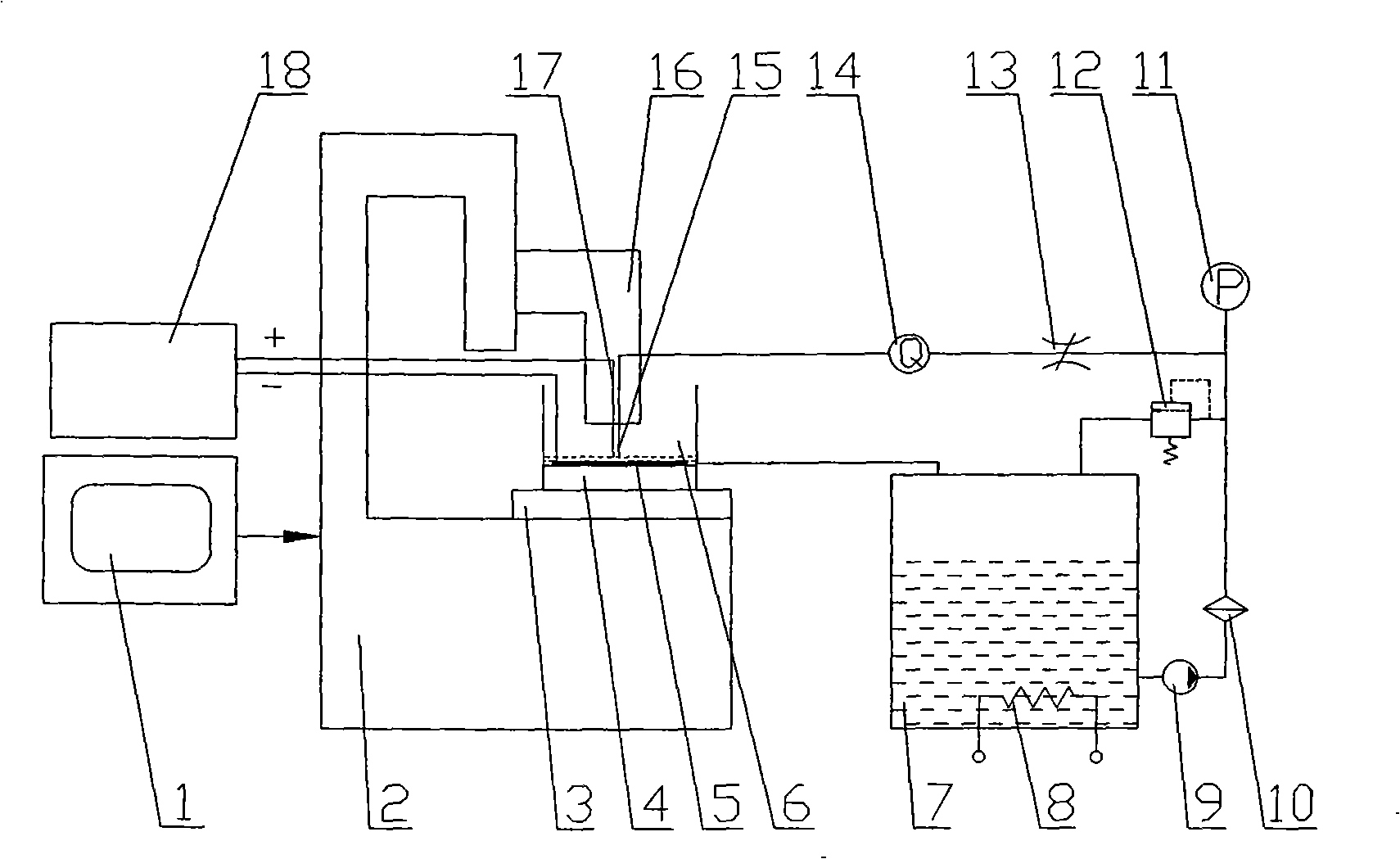

[0022] Such as figure 1 As shown, the cathode 17 is connected to the positive pole of the power supply 18, the cathode plate 5 is connected to the negative pole of the power supply 5, and the electroforming solution is filled with a distance of 0.5 mm in the middle to form a loop. According to the principle of electrochemistry, Cu in the electroforming solution 2+ Under the action of an electric field, electrons are obtained on the cathode plate and reduced to atoms, which are finally deposited. The essence of numerical control selective electrochemical deposition rapid prototyping is to use the principle of electrochemical deposition to circulate a very high-concentration electroforming solution in the deposition tank to provide sufficient metal ions for deposition, and then connect the very fine anode to the positive electrode , the cathode plate is connected to the negative electrode, so that there is an electric field passing between the very thin cathode and anode, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com