Persimmon powder and production process thereof

A production process and a technology for persimmon powder, applied in the field of persimmon powder and its production process, can solve the problems of no concentration of persimmon chemical components, refining chemical raw materials, singleness, etc., and achieve the effect of relieving the pressure of fresh fruit sales and having broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention: the production technology of persimmon powder: get the green persimmon of fruit thinning stage, through pretreatment (raw material selection, high-pressure spray cleaning, ozone bubble cleaning, hairbrush cleaning, stalk removal, high-pressure spray cleaning and ozone Bubble cleaning), crushing, squeezing the juice, adding 1% by weight of sodium erythorbate and 0.05% by weight of citric acid to the gained juice to protect the color, and then processing it with pomace respectively according to the following steps:

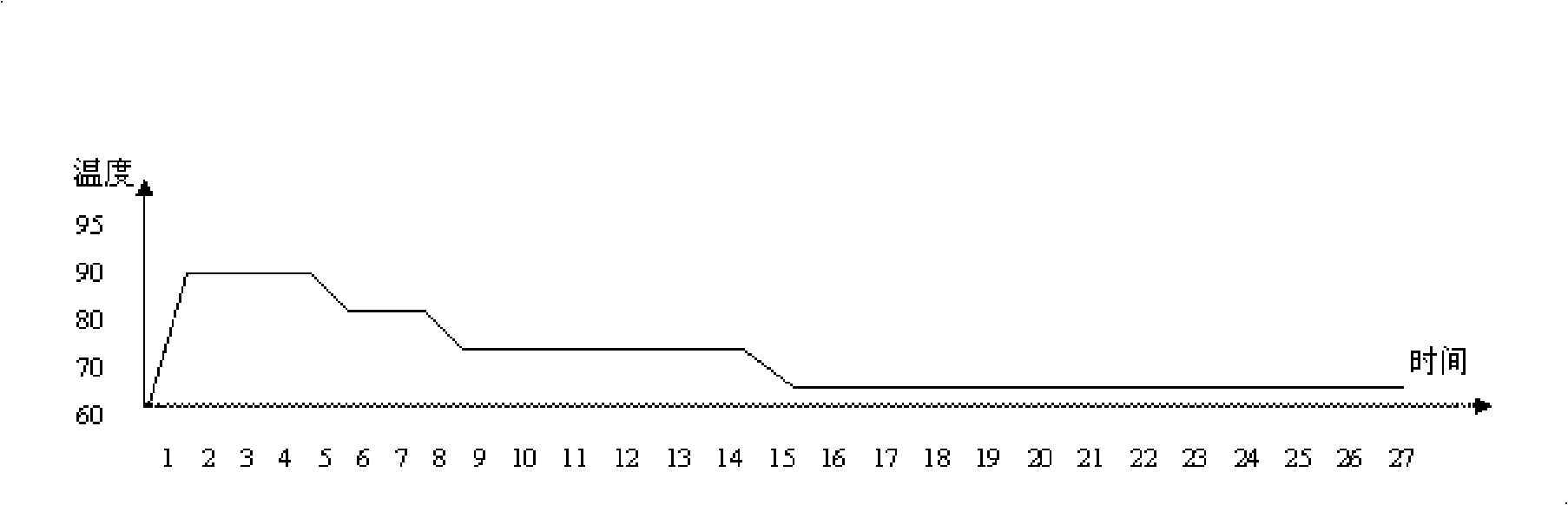

[0027] (1) Enzymolysis of juice: get the compound enzyme of 0.5% of green persimmon juice weight (from the pectinase of activity ≥ 4000 μ / g, the β-amylase of activity ≥ 6000 μ / g, the protease of activity ≥ 300 μ / g, the protease of activity ≥ 300 μ / g 80000μ / g xylanase, cellulase activity ≥ 600μ / g and β-glucanase activity ≥ 100000μ / g), according to the common activity requirements of these enzymes, in the production process...

Embodiment 2

[0030] Embodiment 2 of the present invention: the production process of persimmon powder: get immature green persimmons, through pretreatment, crush, squeeze the juice, add 1% sodium erythorbate by weight to the gained juice to protect the color, then press the pomace respectively The above steps are processed:

[0031] (1) Enzymolysis of juice: get the compound enzyme of 10% of green persimmon juice weight (from the pectinase of activity ≥ 4000 μ / g, the β-amylase of activity ≥ 6000 μ / g, the protease of activity ≥ 300 μ / g, the protease of activity ≥ 300 μ / g 80000μ / g xylanase, cellulase activity ≥ 600μ / g and β-glucanase activity ≥ 100000μ / g), according to the common activity requirements of these enzymes, in the production process, the enzyme is first Dissolve in water, keep at 35°C for 60 minutes to activate, then add to weakly acidic reaction liquid, because the pH value of green persimmon juice is 4-5, so there is no need to add acid to adjust the pH value, you can directly ...

Embodiment 3

[0034] Embodiment 3 of the present invention: the production technology of persimmon powder: get the hard persimmon of turning yellow, through pretreatment, crush, extract juice, gained juice and pomace are processed according to the following steps respectively:

[0035] (1) Enzymolysis of juice: get 0.1% compound enzyme of persimmon juice weight (by pectinase with activity ≥ 4000 μ / g, β-amylase with activity ≥ 6000 μ / g, protease with activity ≥ 300 μ / g, activity ≥ 300 μ / g 80000μ / g xylanase, cellulase activity ≥ 600μ / g and β-glucanase activity ≥ 100000μ / g), according to the common activity requirements of these enzymes, in the production process, the enzyme is first Dissolve in water, keep at 25°C for 120 minutes to activate, then add to weakly acidic reaction liquid, because the pH value of persimmon juice is 4-5, so there is no need to add acid to adjust the pH value, you can directly add activating enzyme to maintain The temperature of the juice is enzymatically hydrolyzed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com