Installation platform of electric locomotive main transformer

A technology for main transformers and electric locomotives, applied in the directions of transporting passenger cars, hoisting devices, transportation and packaging, etc., can solve the problems of long disassembly or installation time, high labor intensity of workers, difficult positioning, etc., and achieves short disassembly or installation time. The effect of labor intensity and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

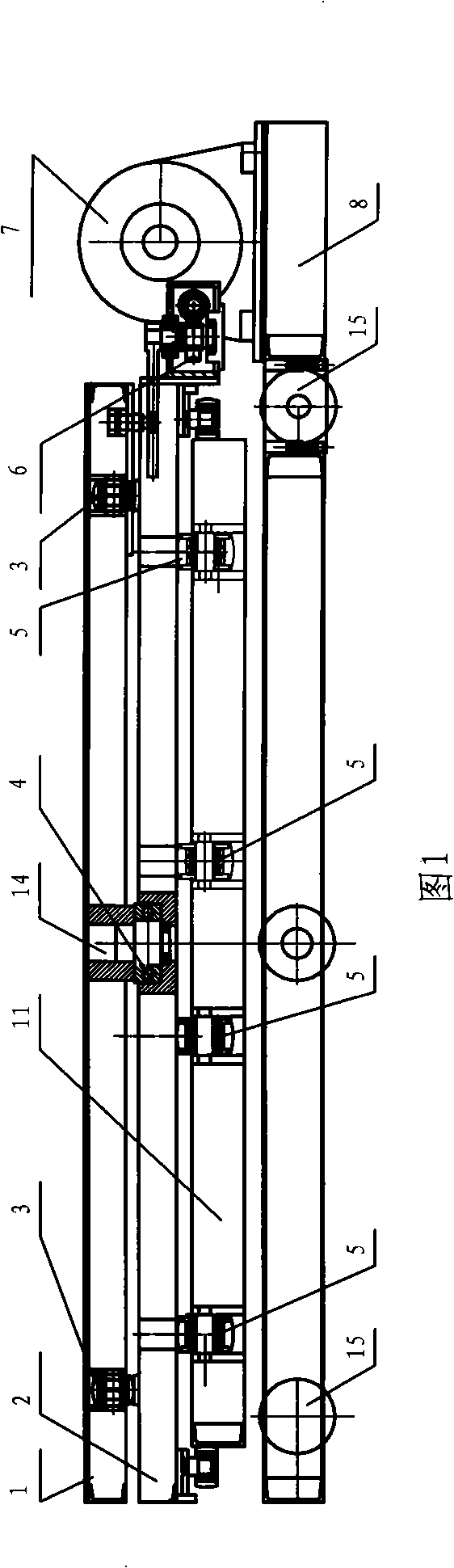

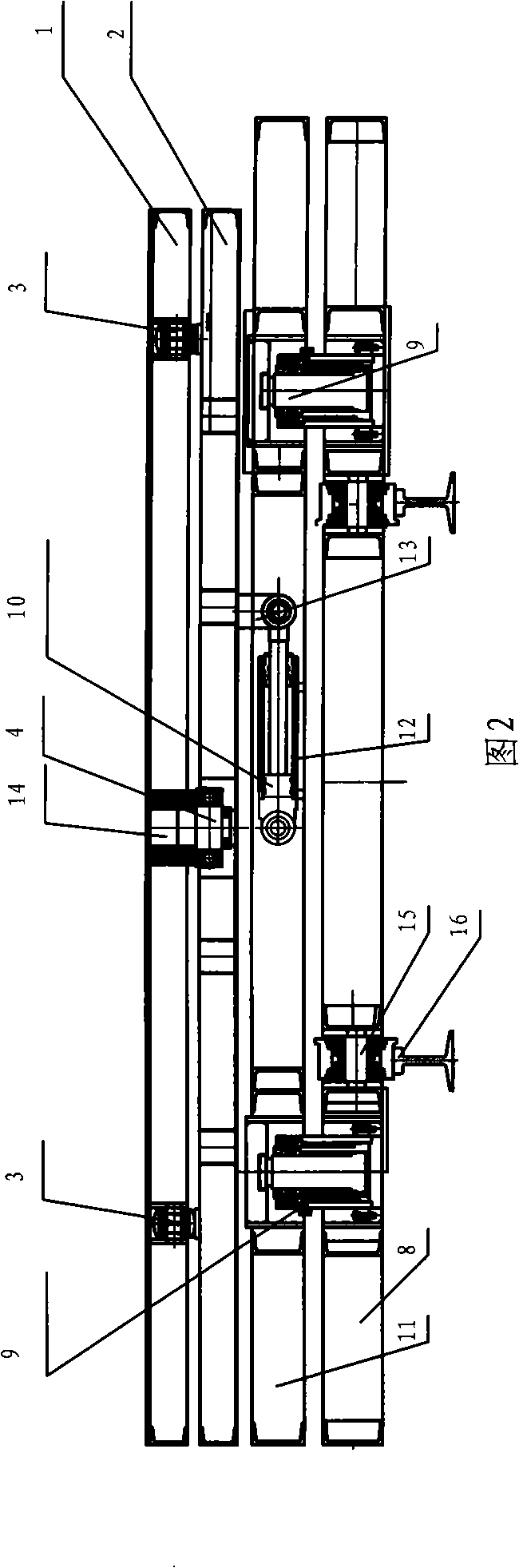

[0022] The specific embodiment of the present invention is as shown in the accompanying drawings: the installation platform of the main transformer of the electric locomotive comprises a traveling part, and the traveling part has a plane car body 8, a traveling motor 17, a traveling speed reducer 7, and rail wheels 15. Lifting platform 11, side shifting platform 2 and turntable 1 are housed on the plane vehicle body 8 of running part. The lifting platform 11 is connected with the plane car body 8 of the running part through four lifting cylinders 9, the side shifting platform 2 is installed on the lifting platform 11, and the middle part of the upper plane of the lifting platform 11 and the lower plane of the side shifting platform is equipped with A side-shift oil cylinder 10; the cylinder body 12 of the side-shift oil cylinder 10 is fixedly connected in a horizontal position on the upper plane of the lifting platform 11. The piston rod of the lateral displacement oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com