High-repeat frequency photonic crystal fiber ultraviolet ultrashort-pulse laser machine

A technology of photonic crystal fiber and ultrashort pulse laser, which is applied in the direction of laser, cladding fiber, optical waveguide and light guide, etc., can solve the problems of limited processing accuracy and application space, high follow-up operation cost, and toxic gas working medium, etc., and achieve structural Simple, narrow pulse width, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

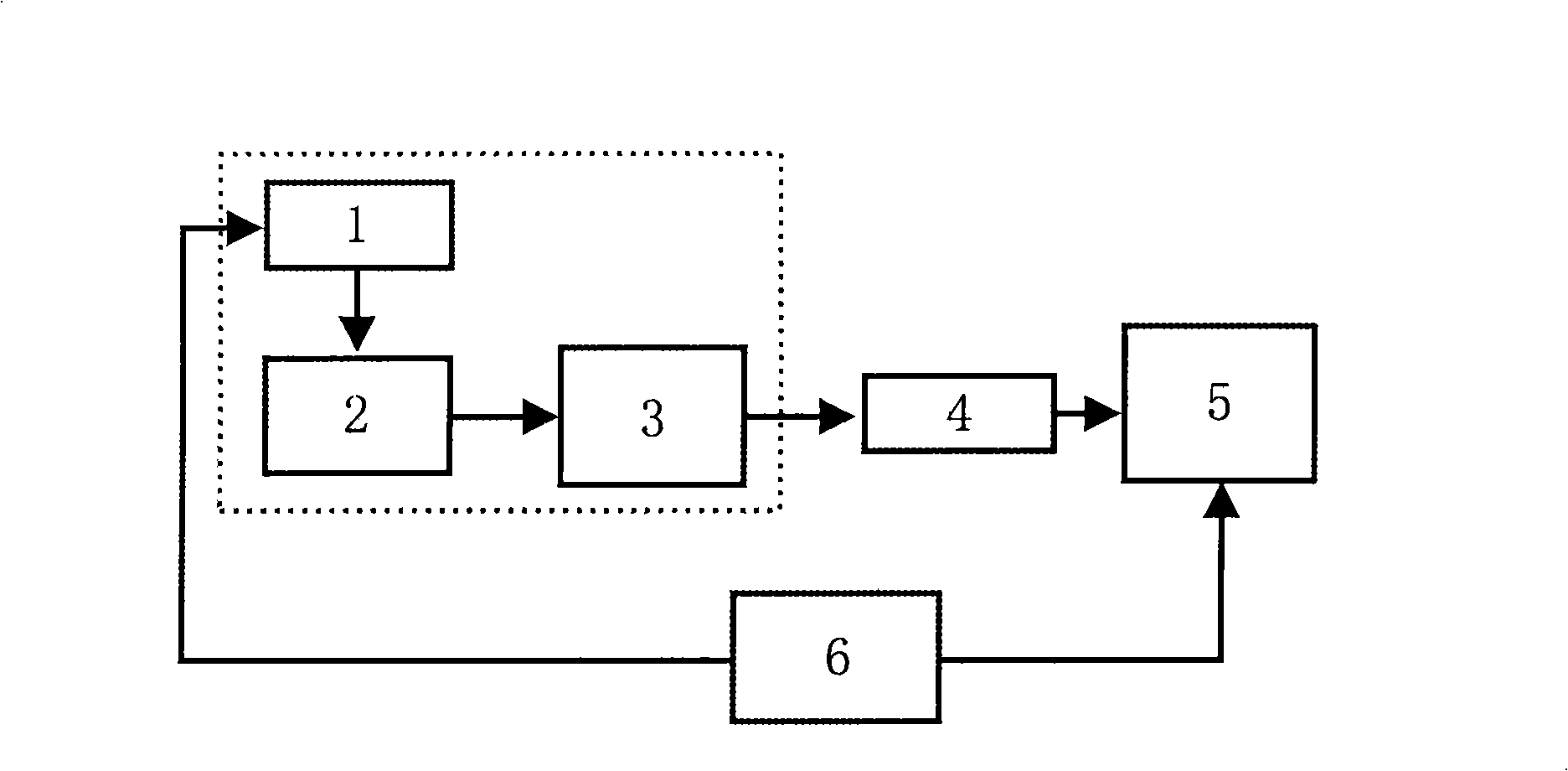

[0022] The high repetition frequency photonic crystal fiber ultraviolet ultrashort pulse laser processing machine of the present invention is as attached figure 1 As shown, the specific examples are as follows:

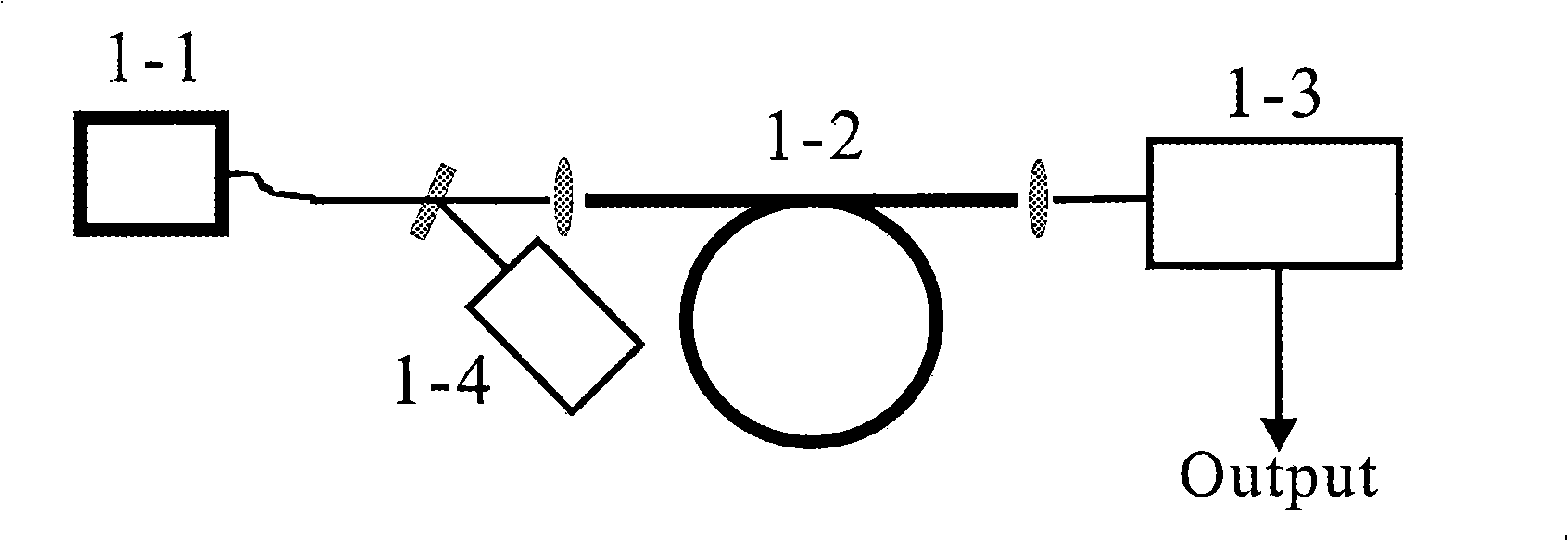

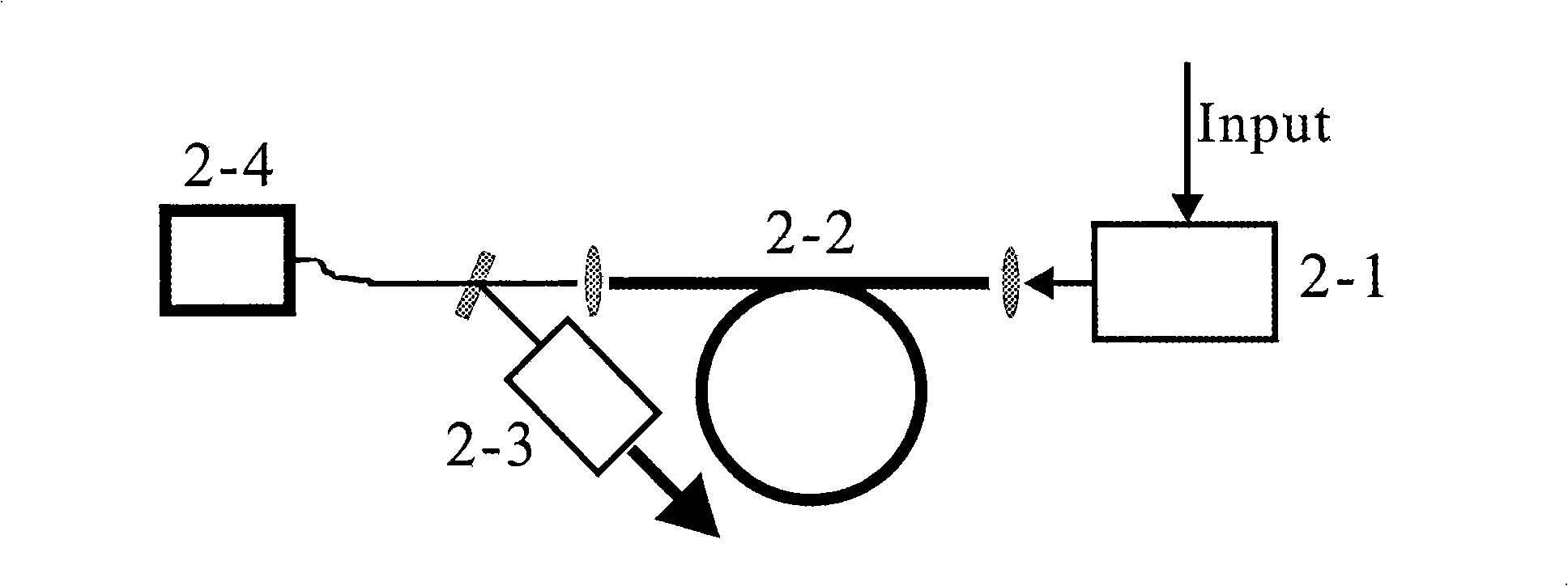

[0023] The laser oscillation level is as figure 2 For the photonic crystal fiber laser shown, the gain medium is Yb-doped large-mode double-clad polarization-maintaining photonic crystal fiber 1-2, the core diameter is 25 microns, the NA is 0.03, the outer cladding diameter is 250 microns, the NA is 0.5, and the length is 3.5m, the two ends have been collapsed and polished to beveled directly for cladding pumping, or welded with SMF of appropriate length, and pumped by WDM; the oscillation stage uses 10W LD1-1 for single-sided or double-clad pumping One end of the resonant cavity adopts semiconductor saturable absorbing mirror and polarization rotation mixer mode-locking 1-3 as the output port, and the other end of the resonant cavity adopts grating pair or large ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com