Plant protection film agent

A protective film agent, plant technology, applied in the direction of plant protection cover, plant growth regulator, animal repellent, etc., can solve the problems of single function of inorganic salt film, affect plant photosynthesis, unfavorable plant growth, etc., to increase field Longevity period, prevention of freezing damage to branches, and effect of resistance to rain erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, add 350Kg of water into a 500L reactor, and add 50Kg of hydroxypropyl methylcellulose under stirring to dissolve completely. Then add 300Kg of water into the 1000L reactor, heat it to 70°C, add 30Kg of gelatin under stirring, after it is completely dissolved, add 10Kg of sodium dodecylsulfonate and 100Kg of sodium humate, and add the above 400Kg after cooling Hydroxypropyl methylcellulose aqueous solution, 80Kg polyvinyl acetate emulsion, 20Kg nanometer white carbon black and 60Kg polyoxyethylene lauryl ether, stir 1h, obtain dark brown homogeneous suspension, material pH value 7.6, viscosity (coat-4 cup, 25°C) for 94 seconds, and the product is packaged.

Embodiment 2

[0027] First, add 300Kg of water into a 500L reactor, and add 30Kg of hydroxypropyl methylcellulose under stirring to dissolve completely. Then add 350Kg of water into the 1000L reactor, heat to 80°C, add 20Kg of gelatin under stirring, and after it is completely dissolved, add 10Kg of sodium octylsulfonate and 120Kg of ammonium humate, and then add the above 330Kg of hydroxypropyl Aqueous methyl cellulose solution, 110Kg polyvinyl acetate emulsion, 10Kg nanometer white carbon black and 50Kg polyoxyethylene lauryl ether, stir 1.5h, obtain the uniform suspension of dark brown, material pH value 6.8, viscosity (coat-4 cups , 25°C) for 76 seconds, and the product is packaged.

Embodiment 3

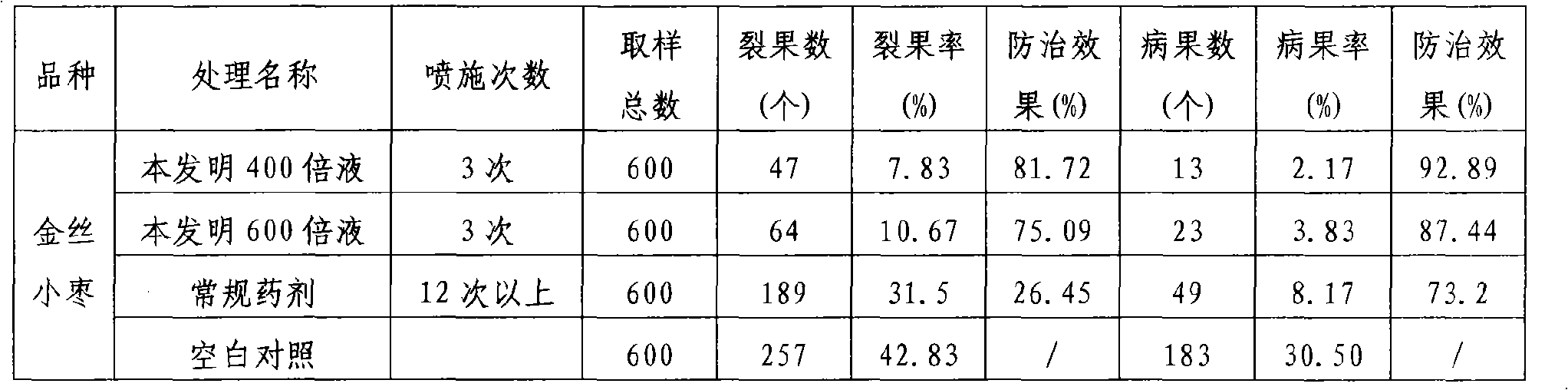

[0029] In order to understand the preventive effect of the film agent of the present invention on apple tree rot, and to provide a scientific basis for popularization and application in the future, the film agent of the present invention was used in 2006 to smear and rot the 13-year-old red Fuji orchard in Zhang Haifang, Beixin Village, Beixin Township, Linyi County. Lesion test, and compared with related chemicals, water as control, the test results are shown in the table below:

[0030] Table 1 plant protective film agent of the present invention prevents and treats fruit tree rot field test summary

[0031]

[0032] As can be seen from Table 1, the plant protective film agent of the present invention has a control effect of 94.15% on apple tree rot, which is obviously higher than other agents. After smearing the film agent of the present invention, the callus grows obviously, and the lesion heals quickly without any adverse effect on the growth and development of the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com