Music string and instrument comprising said string

A string and music technology, applied in the field of music strings, can solve the problems of reducing string vibration, brightness reduction, and sound quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The test wire is made of precipitation hardening stainless steel with the following approximate composition (all in weight percent):

[0053] C 0.01%

[0054] Si 0.2%

[0055] Mn 0.3%

[0056] Cr 12%

[0057] Ni 9%

[0058] Mo 4%

[0059] Co 0.6%

[0060] Ti 0.9%

[0061] Cu 2%

[0062] Al 0.3%

[0063] The balance Fe and impurities usually present.

[0064] The alloy meets the standards according to the US standard AISI UNS S46910.

[0065] The wires were cold drawn into diameters of 0.254 mm, 0.33 mm, and 0.43 mm, respectively. One wire of each diameter is now heat-treated at 475°C for 10 minutes, resulting in an increase in the strength of the material and a further increase in relaxation resistance.

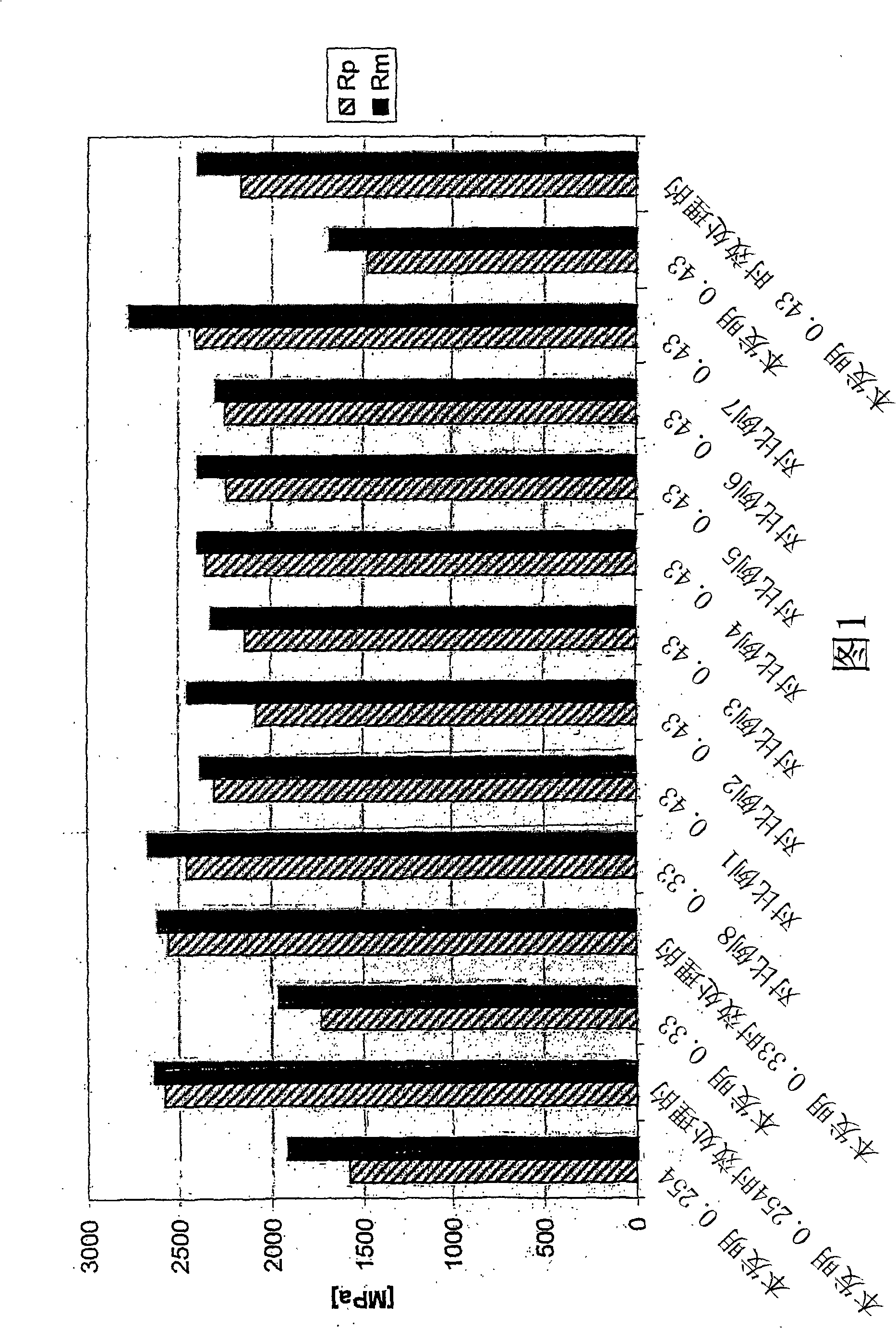

[0066] The yield strength and tensile strength were measured by the tensile test according to SS-EN10002-1, and the comparative examples of 8 different carbon piano strings were compared. The approximate composition and string diameter of the comparative example are shown ...

Embodiment 2

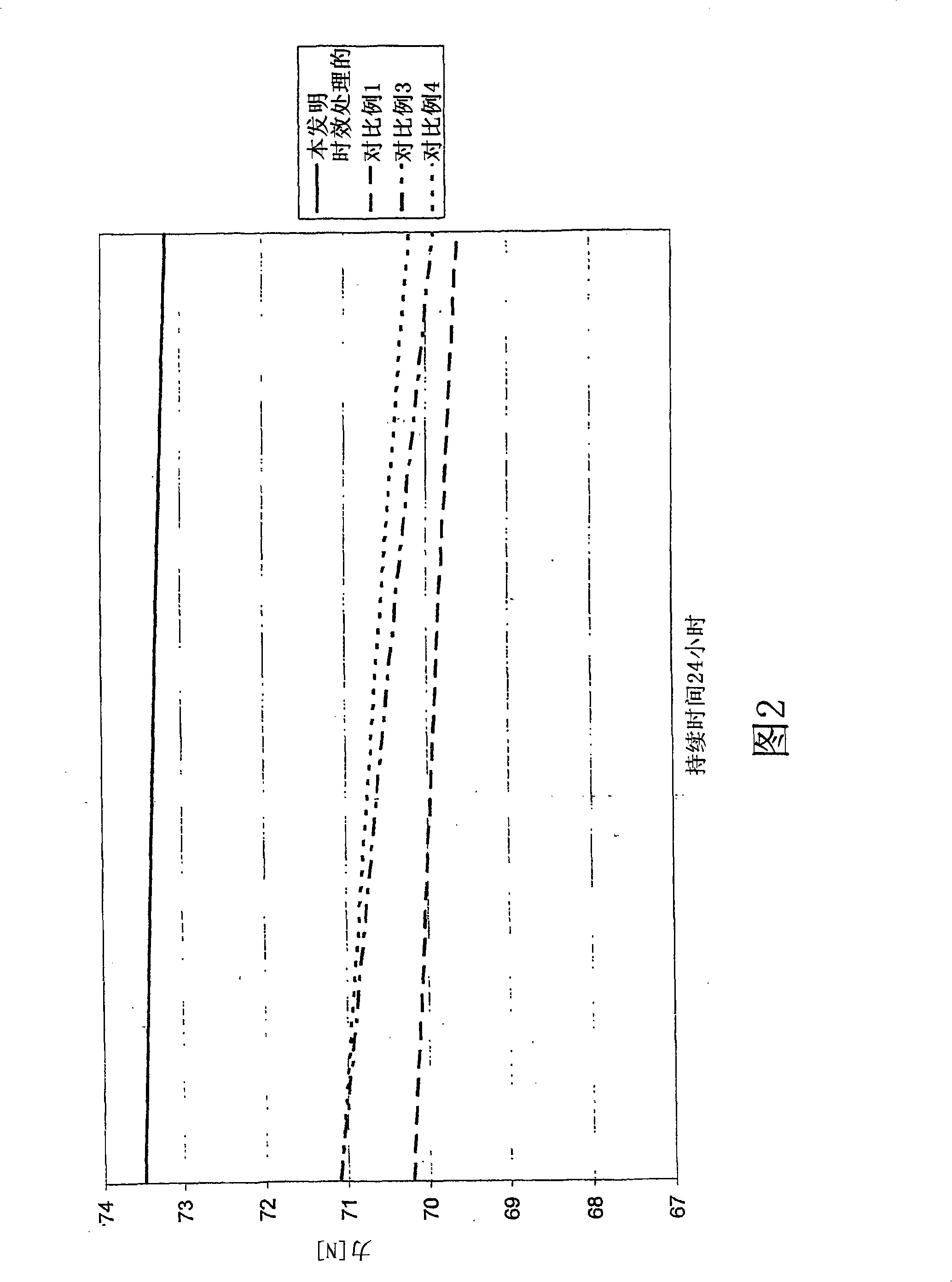

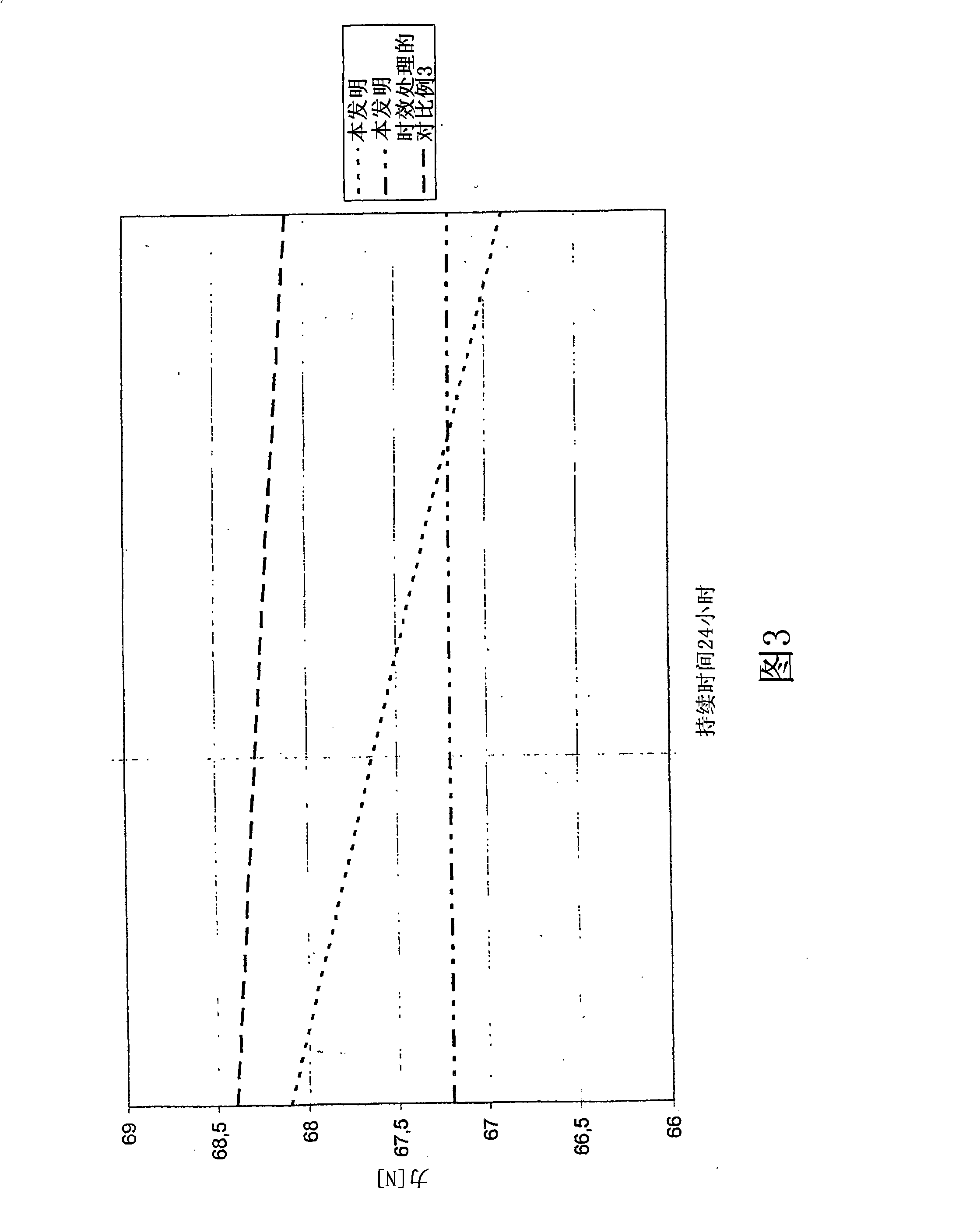

[0072] The relaxation resistance was tested by plucking strings of 0.254 mm, 0.33 mm diameter, and 0.43 mm diameter with the plectrum about 200 times per minute. The ingredients are those of Example 1. The test was conducted for more than 24 hours. The plucking position of the piano is set at a distance of 18 cm from the force sensor connected to the computer. The total length of each string is 65cm, and each end of the string rests on two plastic pieces. The distance between each end point and its corresponding force sensor is 5 cm. The diameter and its corresponding audio frequency as well as the initial tension and engineering stress of the strings are given in Table 3.

[0073] table 3

[0074] Diameter [mm]

Audio [Hz]

Tension [N]

Engineering stress [MPa]

0.254

330

71.8

1417

0.33

247

68.5

801

0.43

196

73.9

509

[0075] The slack test results of strings with diameters of 0....

Embodiment 3

[0083] The magnetic resonance of the alloy in Example 1 was tested on a guitar and compared with the magnetic resonance of the alloy in Comparative Example 7. The string is plucked at a distance of 10 cm from the bridge and is subjected to a force corresponding to the breaking point of the 0.10 mm copper wire. The copper wire is looped vertically around the plucked string, and then pulled until it reaches the breaking point. In this way, the same force is applied for each test. The breaking point of the copper wire must also be the point in contact with the plucked string. If the copper wire breaks at any other point, repeat the process. A set of five approved tests are performed on each string, and the results are shown in the graphs according to Figures 5 and 6. The results show that the aging process does not affect the magnetic properties of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com