Method for integrating inner-humidification fuel batter with proton exchange film

A proton exchange membrane and fuel cell technology, which is applied to fuel cell components, solid electrolyte fuel cells, fuel cells, etc., can solve the problems of inability to uniformly manufacture and use materials, waste materials, and reduce the power density of battery packs. working area, improving integration compactness, increasing the effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

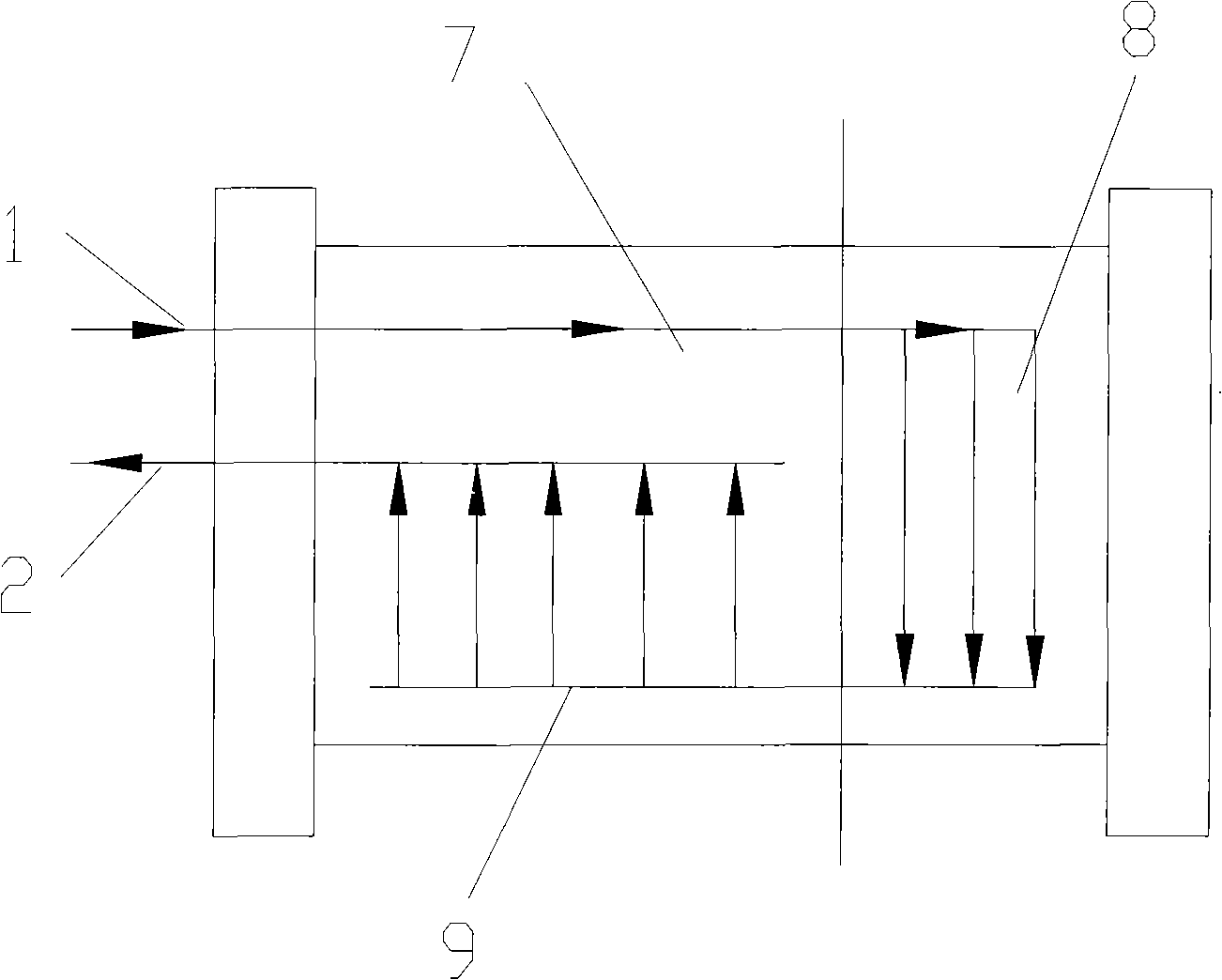

[0059] An integrated method for internally humidified proton exchange membrane fuel cells, such as Figure 5 As shown, the method is to integrate two groups of fuel cell stacks A and B into an integrated assembly, and a central collector plate 12 is arranged in the middle of the two groups of fuel cell stacks, and the fuel cell stacks A and B respectively include humidification sections A1 and B1 and the power generation section A2, B2, the humidification section A1, B1 is close to the central collector plate 12, the power generation section A2, B2 is close to the rear collector end plate 13 at the end, and the central collector plate 12 is provided with an air inlet 1, a hydrogen inlet 2, Cooling water outlet 6, air outlet 2, hydrogen outlet 4, cooling water inlet 5 are provided on the end rear collecting end plate 13; Figure 3a , 3b As shown, the air and hydrogen flow in from the air inlet 1 and the hydrogen inlet 2 of the central collector plate 12 in the middle and are d...

Embodiment 2

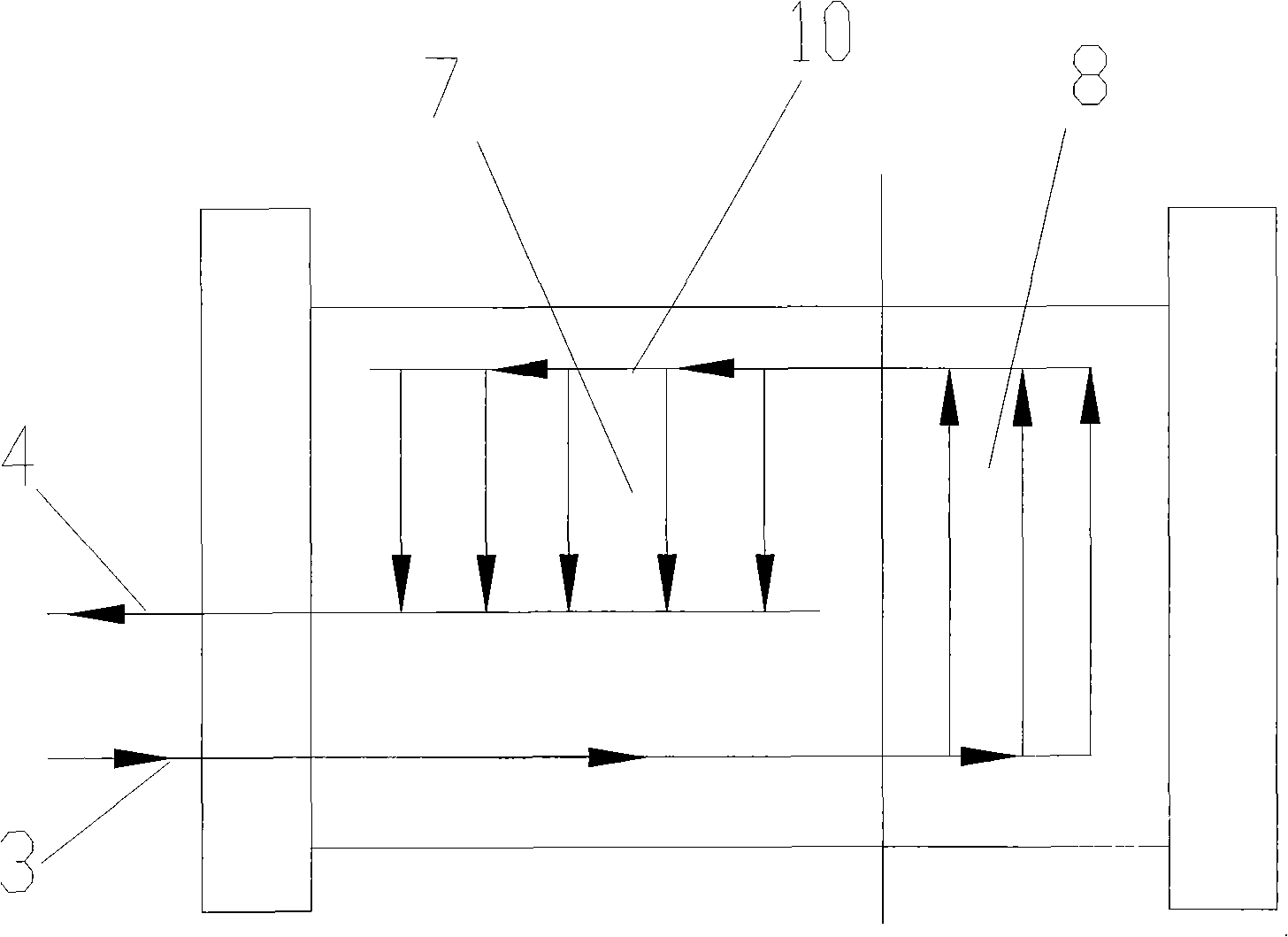

[0063] Such as Figure 7 As shown, it is an integrated fuel cell stack for forklift designed and assembled according to the new method of the present invention. Image 6 As shown, the central collector plate 12 is provided with an air inlet 1, a hydrogen inlet 3, and a cooling water outlet 6, and the collector end plates at the ends of stacks A and B are respectively provided with an air outlet 2, a hydrogen outlet 4, and a cooling water inlet 5. The two groups of fuel cell stacks A and B are respectively arranged at the left and right ends of the central collector plate 12, and hydrogen and air flow in from the air inlet 1 and the hydrogen inlet 2 on the central collector plate 12 and then divide into two branches, which flow into respectively In the humidification sections A1 and B1 of the fuel cell stacks A and B at the left and right ends, the humidified air and hydrogen enter the power generation sections A2 and B2 to undergo electrochemical reactions, and then flow from...

Embodiment 3

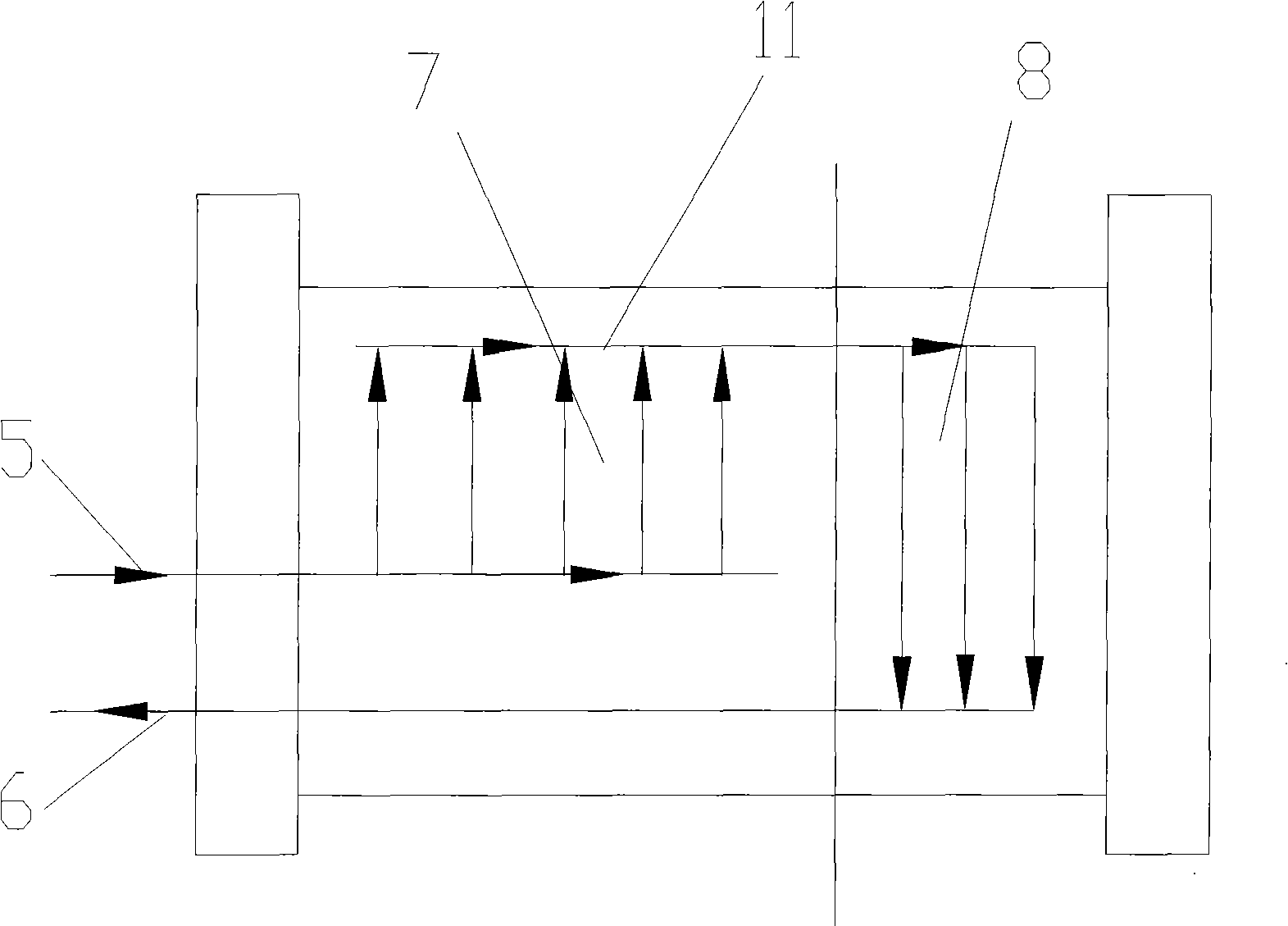

[0066] Such as Figure 8 As shown, it is another integrated fuel cell stack for a forklift designed and assembled according to the method of the present invention. Inlet 1, hydrogen inlet 3, cooling water outlet 6, air outlet 2, hydrogen outlet 4, and cooling water inlet 5 are respectively provided on the collector end plates at the ends of stacks A and B. The two groups of fuel cell stacks A and B are arranged up and down on the same side of the central collector plate 12, and hydrogen and air flow in from the air inlet 1 and hydrogen inlet 2 on the central collector plate 12 and then divide into two branches, which flow into the left and right respectively. Humidification sections A1, B1 of the end fuel cell stacks A, B, after the humidified air and hydrogen enter the power generation sections A2, B2 to undergo electrochemical reactions, then from the terminal rear collector end plate 13 behind the power generation sections A2, B2 The air outlet 2 and the hydrogen outlet 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com