Method for controlling clutch in vehicle transmission system equipped with friction type stepless speed changer

A friction clutch, clutch technology, applied in the direction of clutch, mechanical equipment, etc., can solve the problems of complex, inability to distinguish clutch slip, and the ability of the clutch to suppress torque vibration is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

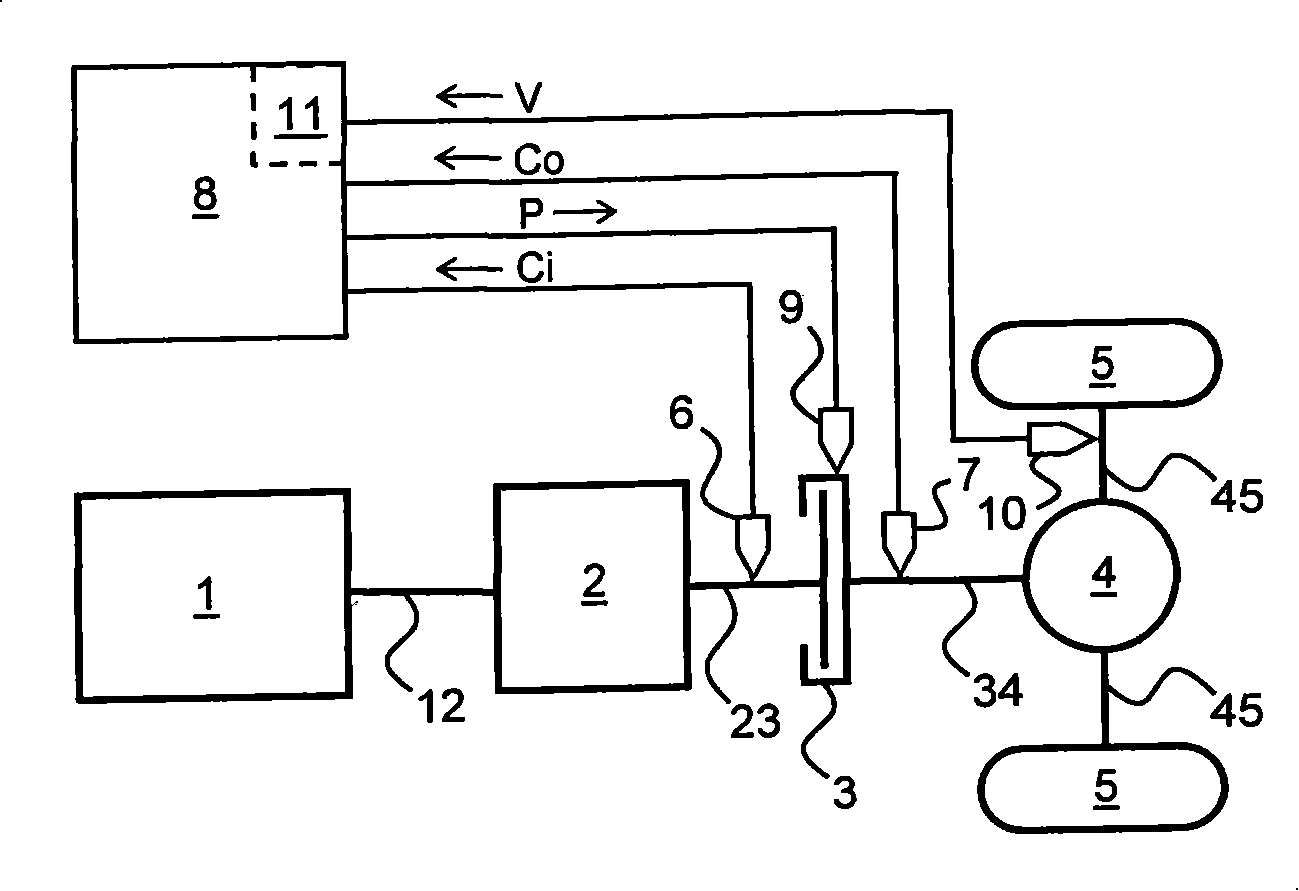

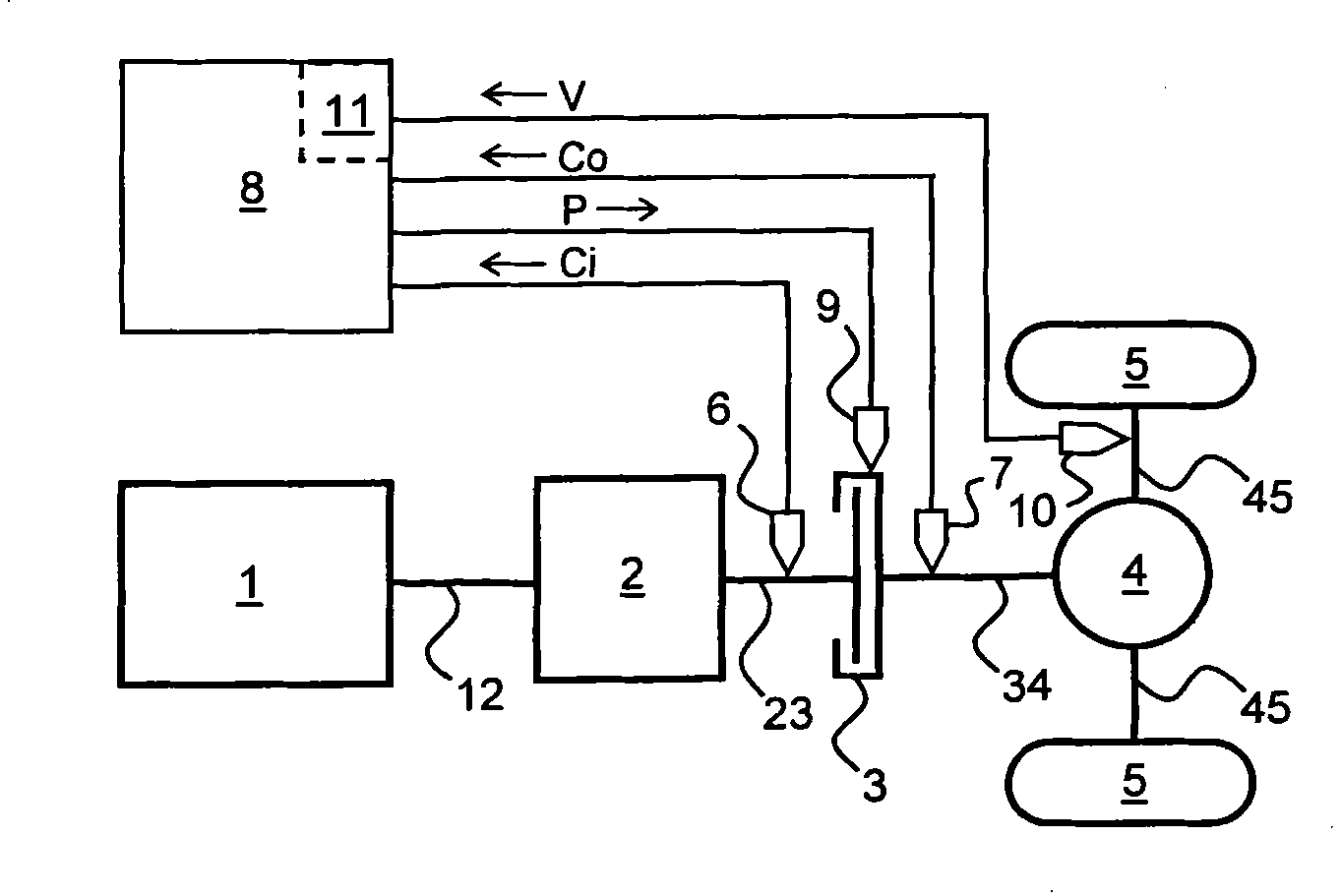

[0015] Figure 1 depicts a vehicle drive train comprising, in order (i.e., in the direction downstream of the driving force) an engine 1, a friction continuously variable transmission 2, a friction clutch 3, a final drive 4 comprising a differential transmission and two driven wheels 5. Transmission shafts 12, 23, 34 and 45 are provided between the components 1-5 of the upper drive train and are connected to them in a driving manner. Also shown schematically in FIG. 1 is a clutch slip control device comprising two rotational speed sensors 6 and 7. An Electronic Clutch Control Unit 8 or "ECCU" and a clutch actuator 9 that controls the actuation of the clutch 3 (for example, by adjusting the hydraulic clutch engagement pressure P).

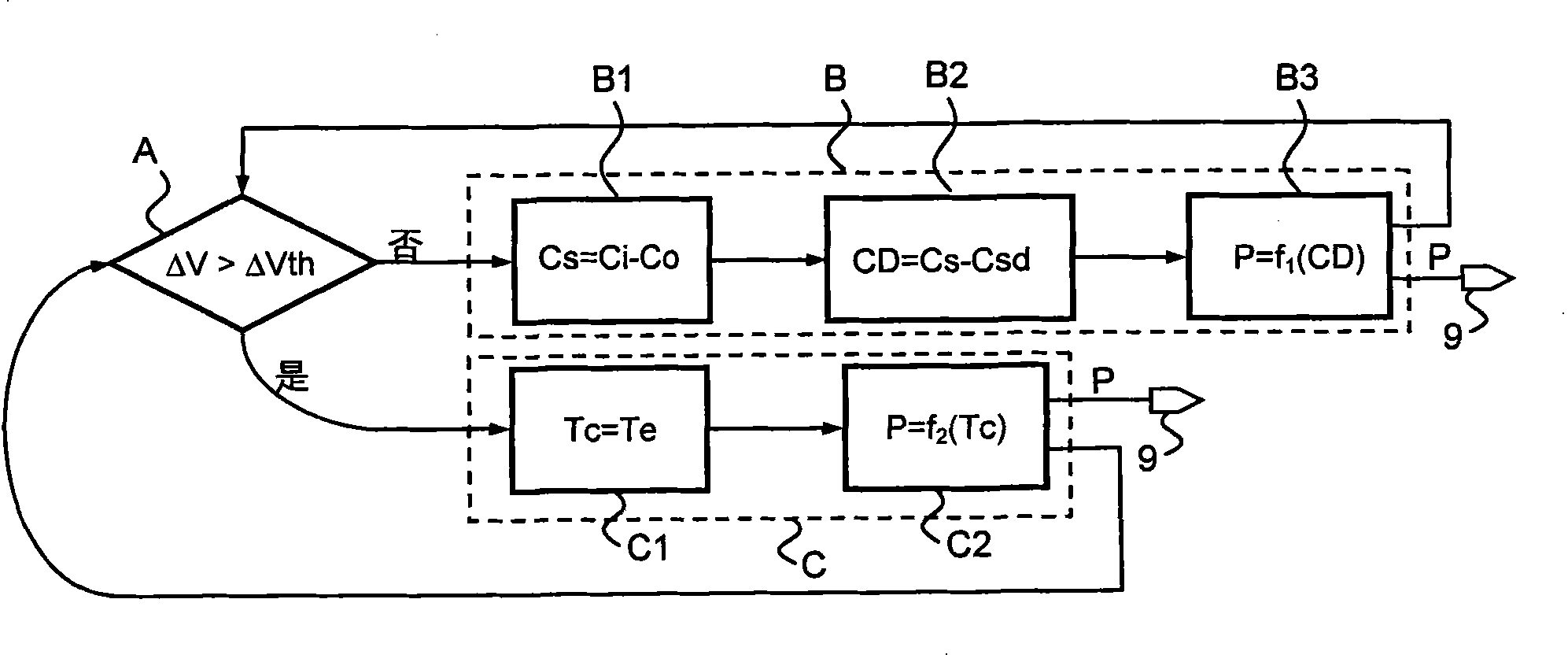

[0016] Based on this, it is known that setting and operating the ECCU 8 achieves a desired clutch slip amount Cs between the input-side speed Ci and the output-side speed Co, that is, Cs=Ci-Co. In this arrangement, when torque vibrations are introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com