Connector

An edge connector, electrical connection technology, applied in the direction of connection, connecting device components, single semiconductor device testing, etc., can solve problems such as increased cost, unoptimized, insufficient aging board current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, various embodiments of the present invention will be described with reference to the drawings. It should be noted that the embodiments described below do not limit the technical scope of the present invention.

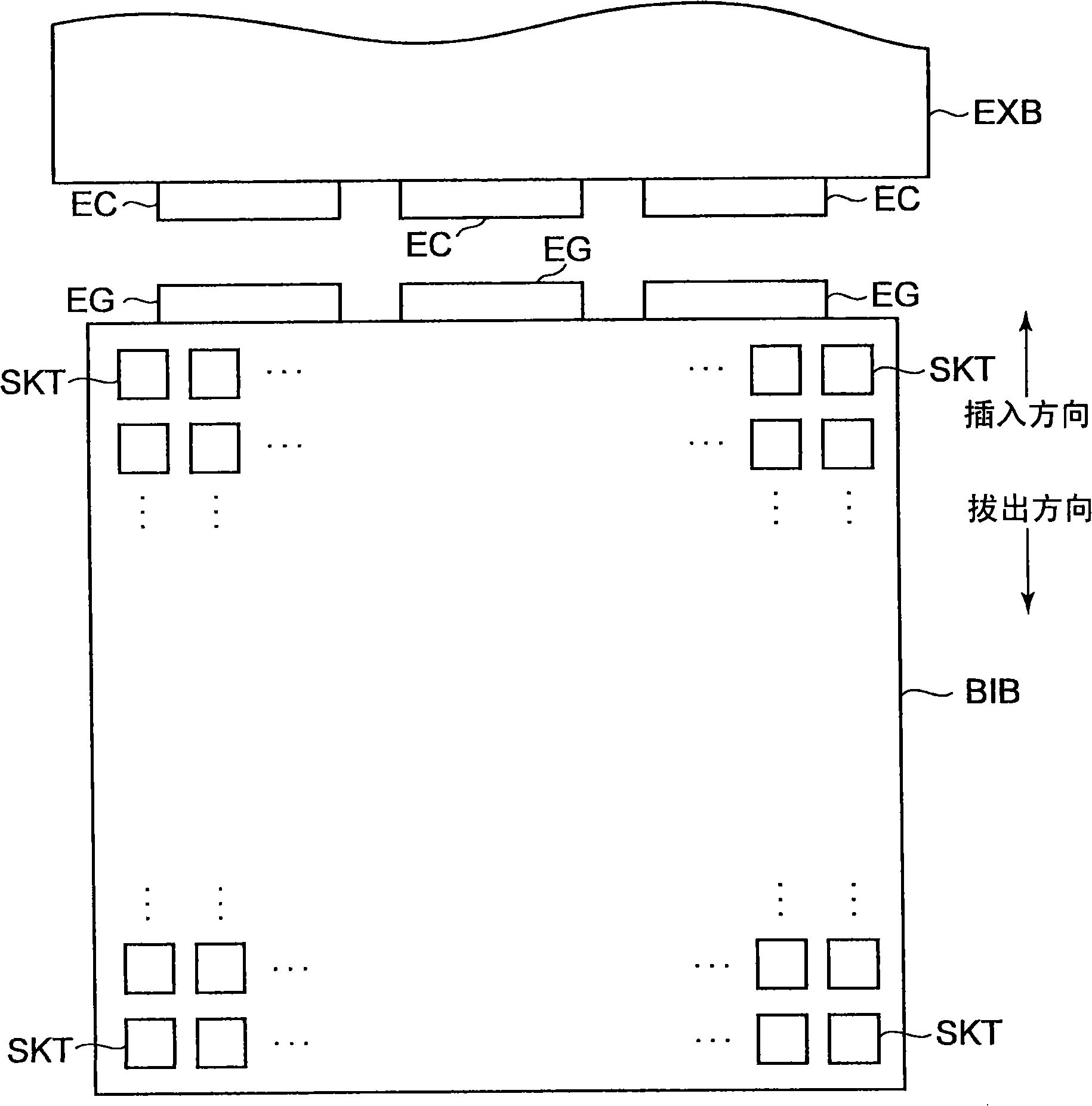

[0055] figure 1 It is a plan view showing the whole of the burn-in board BIB and a part of the edge connector EC side of the extension board EXB according to this embodiment. as it shouldfigure 1 As shown, there are multiple sockets SKT configured in a matrix on the burn-in board BIB. Semiconductor devices serving as devices under test are mounted on the sockets SKT, respectively. The number of sockets SKT provided on a burn-in board BIB is arbitrary. That is, the number of devices under test that can be mounted on one burn-in board BIB is arbitrary.

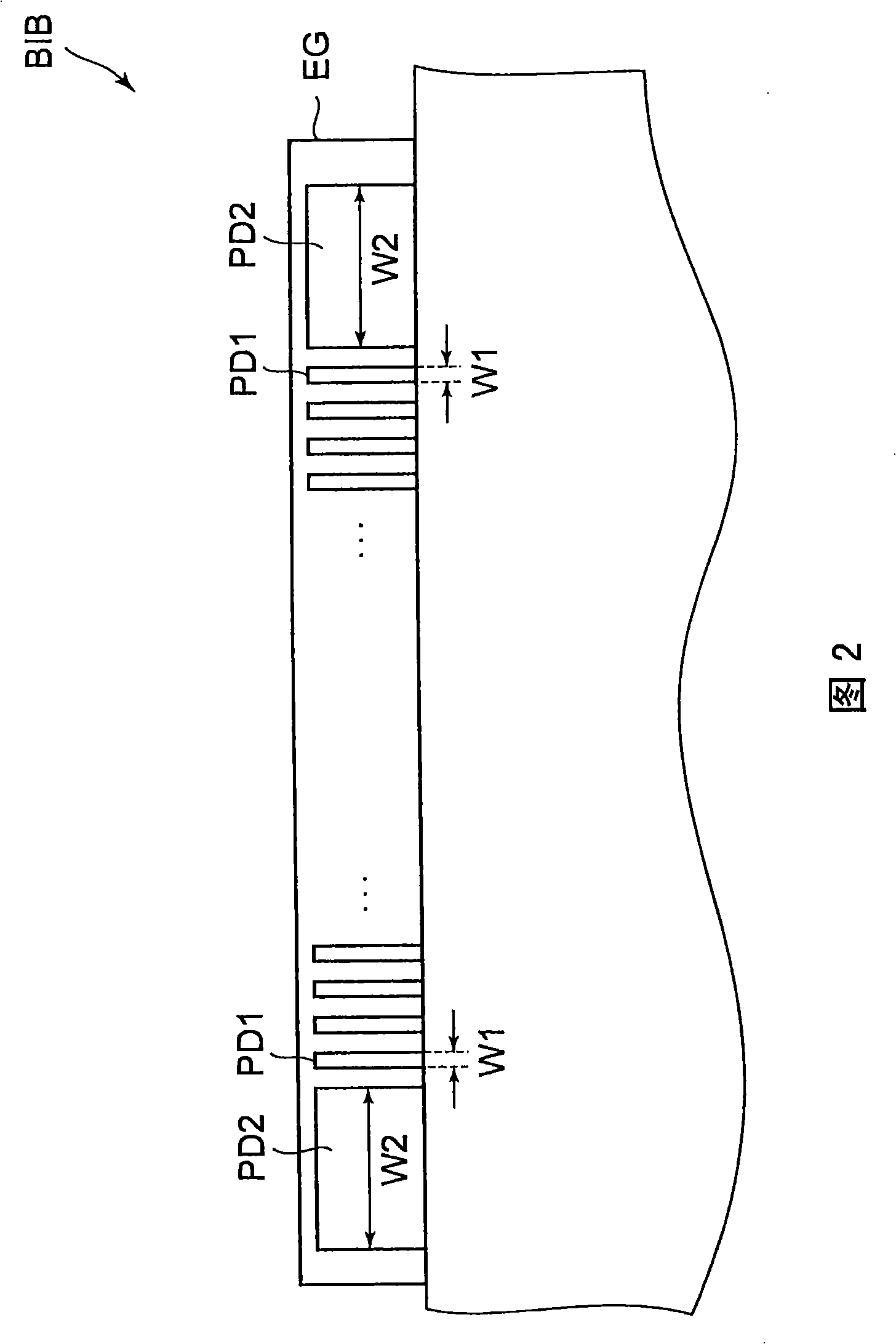

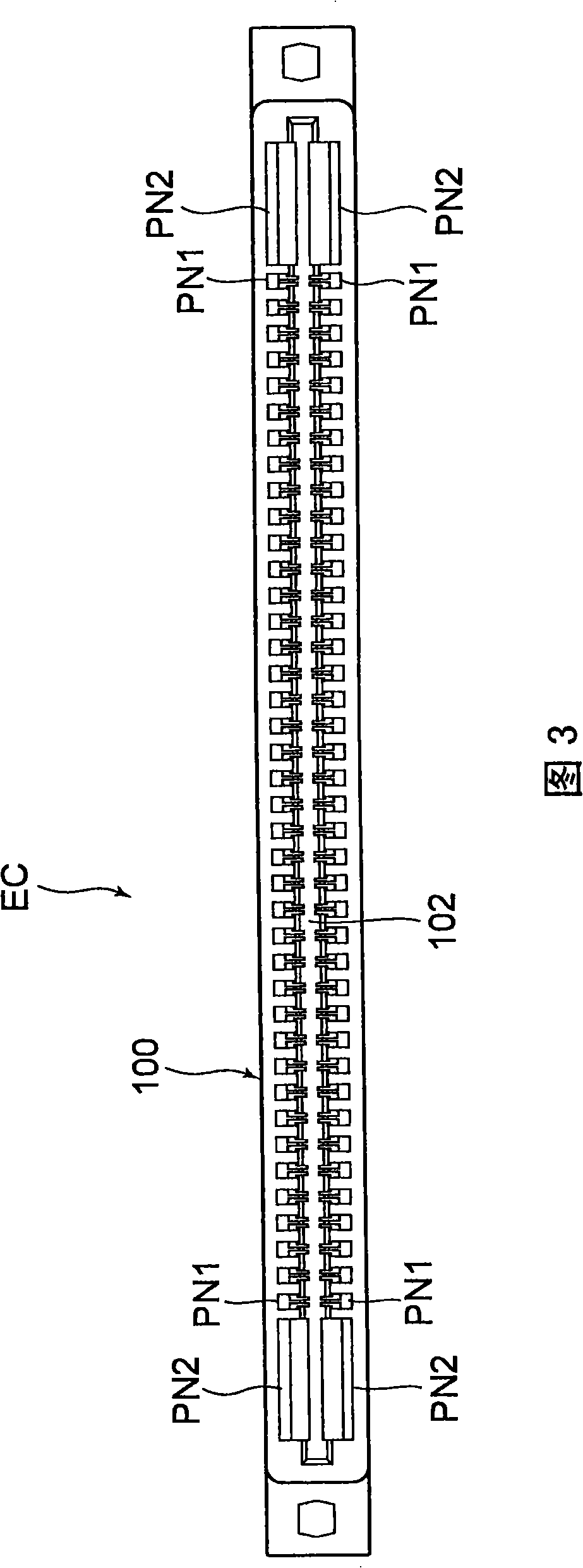

[0056] An insertion edge EG is formed on the front end side in the insertion direction of the burn-in board BIB. In this embodiment, for example, insertion edges EG are formed at three places on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com