Dyeing-assist agent used for aramid fiber dyeing, preparation method and dyeing method thereof

A dyeing aid and aramid fiber technology, applied in the textile field, can solve the problems of reducing the glass transition temperature of aramid fiber, insufficient dyeing depth, low light fastness, etc., and achieve the effects of saving foreign exchange, short process flow and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of dye auxiliaries of the present invention is carried out according to the following steps:

[0053] a. take benzoic acid and methanol respectively, use sulfuric acid as a catalyst, then carry out esterification to obtain methyl benzoate,

[0054] Take hydrogen sulfide and tetrahydrofuran respectively, take Al2 O 3 For catalyst, the reaction obtains sulfolane;

[0055] b. According to mass percentage, respectively take 1%~3% of OP-10, 1%~3% of sodium dodecyl sulfonate, 80%~82% of water, 8%~12% of methyl benzoate obtained in the previous step % and sulfolane 4% to 6%, the total amount of each component is 100%, put it into a high-shear emulsifier for emulsification, control the speed of the emulsifier to be 3000r / min, and the emulsification time to be 30min. Dyeing aids.

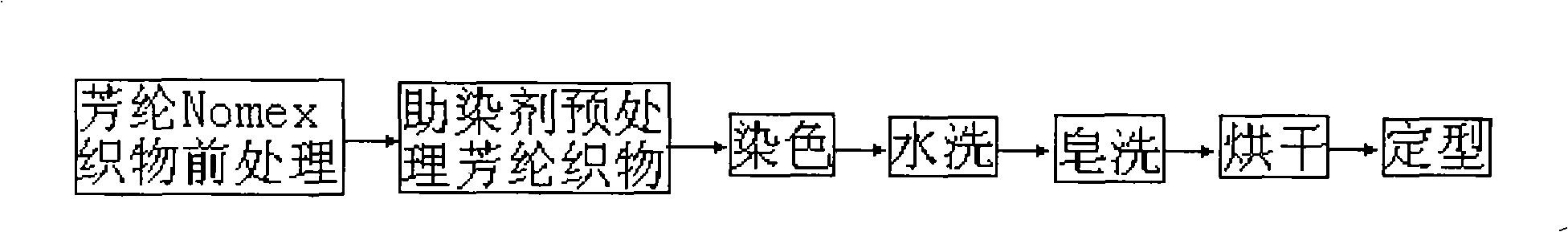

[0056] The present invention utilizes the above-mentioned dyeing auxiliaries to dye aramid fiber, and the process is as follows figure 1 shown.

[0057] Specifically includ...

Embodiment 1

[0076] Step 1: Take benzoic acid and methanol, and use sulfuric acid as a catalyst to carry out an esterification reaction to obtain methyl benzoate; take hydrogen sulfide and tetrahydrofuran, use Al 2 O 3 As a catalyst, the reaction produces sulfolane. Take OP-102Kg, sodium dodecyl sulfonate 2Kg, water 82Kg, methyl benzoate 8Kg and sulfolane 6Kg respectively, the total amount of each component is 100%, put into a high shear emulsifier for emulsification, The rotating speed of the emulsifying machine is controlled to be 3000 r / min, and the emulsifying time is 30 min. After emulsifying, the dyeing auxiliaries are prepared.

[0077] Step 2: Take sodium hydroxide and degreaser DO respectively, and prepare a pretreatment solution for aramid fabrics. The solution was heated to 100°C, put into the fabric, the bath ratio of the solution and the aramid fabric was controlled to be 50:1, boiled for 30 minutes, and then the fabric was taken out for washing and drying;

[0078] Step 3:...

Embodiment 2

[0082] Step 1: Take benzoic acid and methanol, and use sulfuric acid as a catalyst to carry out an esterification reaction to obtain methyl benzoate; take hydrogen sulfide and tetrahydrofuran, use Al 2 O 3 As a catalyst, the reaction produces sulfolane. Take OP-103Kg, sodium dodecyl sulfonate 1Kg, water 81Kg, methyl benzoate 10Kg and sulfolane 5Kg respectively, the total amount of each component is 100%, put into a high shear emulsifier for emulsification, The rotating speed of the emulsifying machine is controlled to be 3000 r / min, and the emulsifying time is 30 min. After emulsifying, the dyeing auxiliaries are prepared.

[0083] Step 2: respectively take sodium hydroxide and degreaser DO, prepare a solution for aramid fabric pretreatment, control the concentration of sodium hydroxide to be 20g / L, and the concentration of degreaser DO to be 4g / L in the solution. The solution was heated to 110°C, put into the fabric, the bath ratio of the solution and the aramid fabric was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com