Synthesis process for chromium picolinate

A kind of technology of chromium picolinate and synthesis technology, applied in the field of synthesis technology of chromium picolinate, can solve the problem that the price of chromium 2-picolinate remains high, affects the popularization and application of chromium 2-picolinate, and the price of 2-picolinate is expensive and other problems, to achieve the effects of controllable pollution, less impurities and high atomic utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

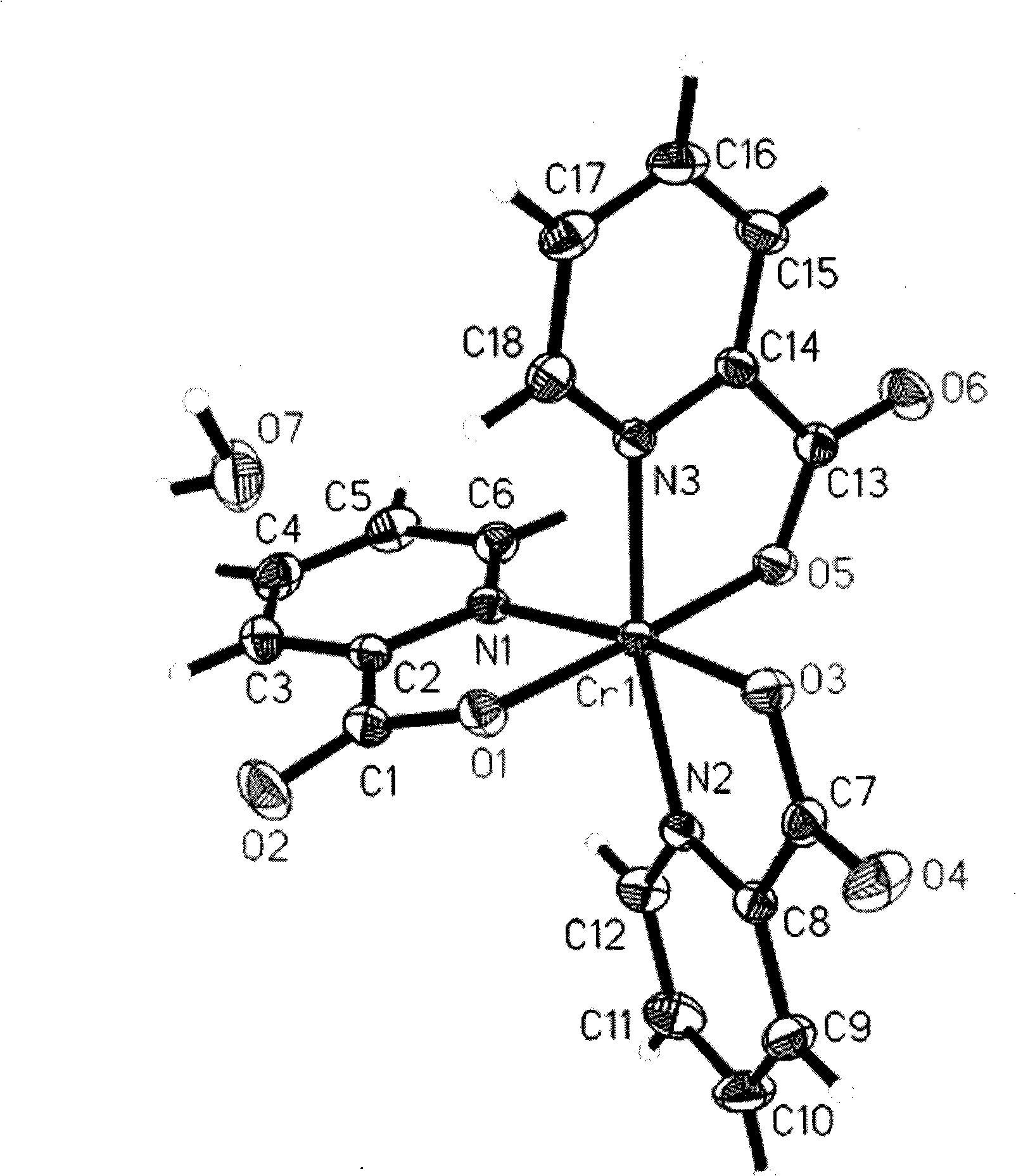

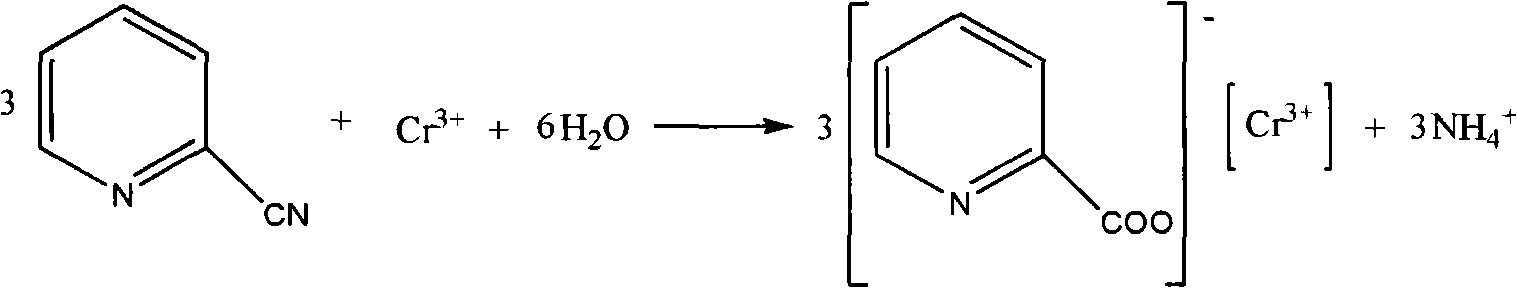

[0026] 2-cyanopyridine and chromium trichloride were added into a 30ml autoclave lined with polytetrafluoroethylene according to the molar ratio of 3:1, and about 20ml of water was added, and the reactor was tightened and heated to 150 degrees. Maintain a constant temperature of 150 degrees for 24 hours under 3 standard atmospheric pressures to generate pink chromium pyridinecarboxylate with a yield of 96.2%.

Embodiment 2

[0028] Add 2-cyanopyridine and chromium trichloride into a 30ml high-pressure reactor lined with polytetrafluoroethylene according to the molar ratio of 3:1, add about 15ml of water, tighten the reactor and heat it to 100 degrees, 2 The standard atmospheric pressure is maintained at a constant temperature of 100 degrees for 24 hours to generate pink chromium pyridinecarboxylate with a yield of 95.6%.

Embodiment 3

[0030] Add 2-cyanopyridine and chromium trichloride into a 30ml high-pressure reactor lined with polytetrafluoroethylene according to the molar ratio of 3:1, add about 20ml of water, tighten the reactor and heat it to 80 degrees, 2 The standard atmospheric pressure is maintained at a constant temperature of 80 degrees for 48 hours to generate chromium pyridinecarboxylate with a yield of 96.5%. The synthesis process has the highest yield and can be used as a preferred embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com