Hole drilling calibration method for printed circuit board

A printed circuit board and positioning technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of affecting the level of the substrate, the inability of the drilling machine to drill accurately, and the gap error, etc., to improve the accuracy of drilling degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

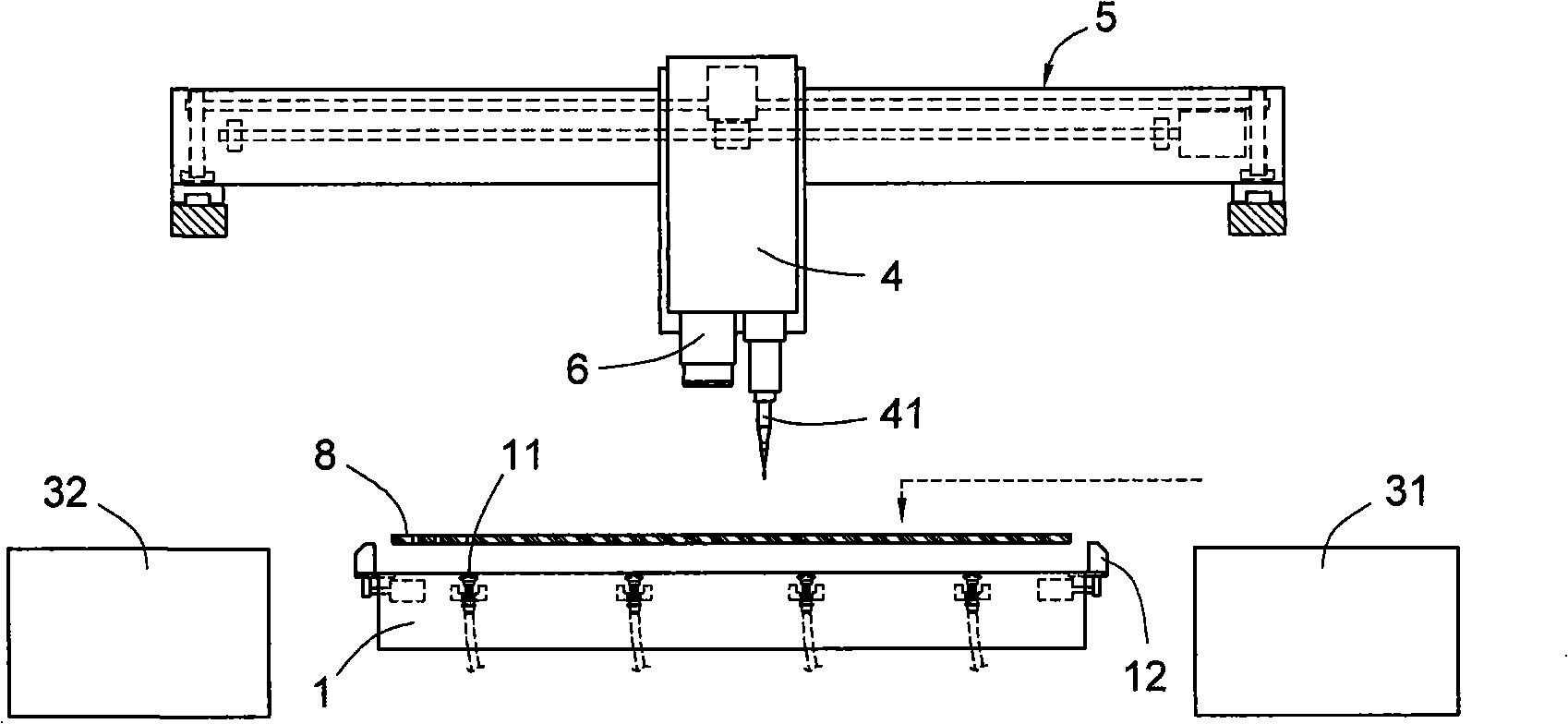

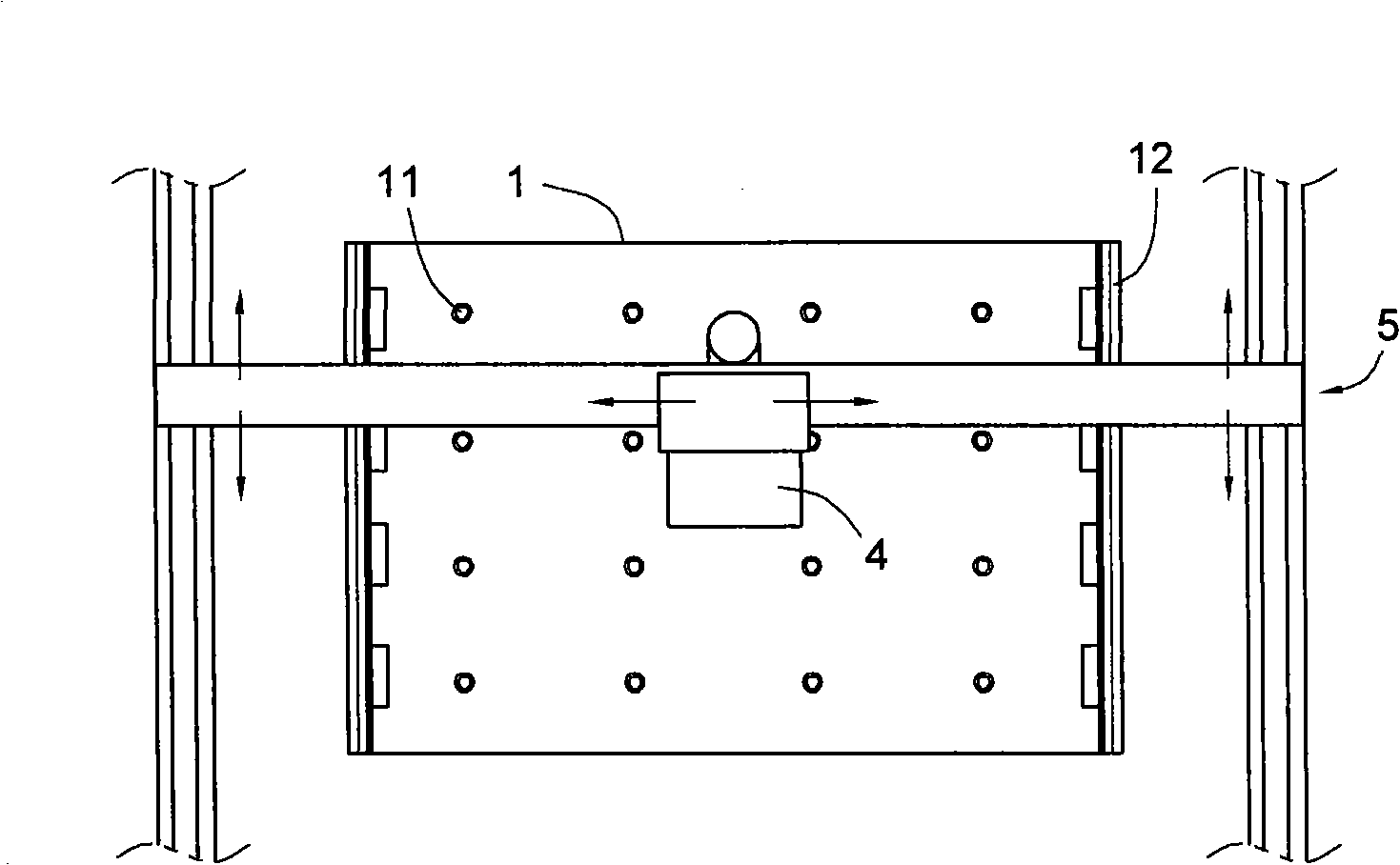

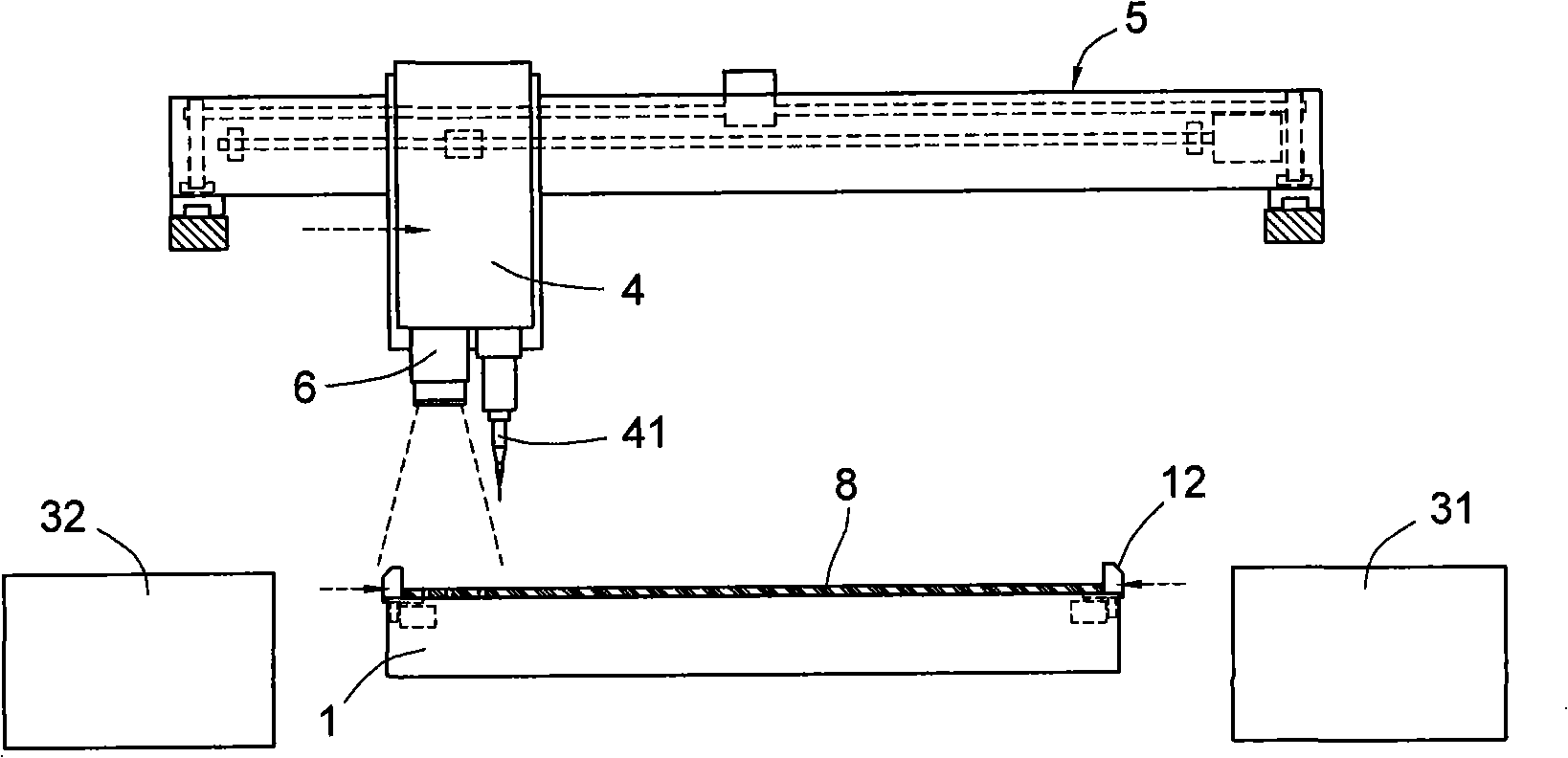

[0030] first as figure 1 As shown, it discloses a schematic configuration diagram of the implementation environment of the first embodiment of the printed circuit board drilling alignment method of the present invention, and cooperates with figure 2 and image 3 Illustrate that the implementation environment of the present invention includes:

[0031] A bed 1, interposed between a discharge device 31 and a receiving device 32, the discharge device 31 can transfer the substrate 8 to the bed 1, and the receiving device 32 can pick up the substrate 8 on the bed 1 , to transfer to the subsequent processing area station, and the bed 1 has a plurality of negative pressure holes 11 capable of adsorbing the positioning of the substrate 8, a set of corresponding clamps 12 or a clamping groove capable of clamping the positioning of the substrate 8;

[0032] A drilling machine 4 is slidably arranged on the top of the bed platform 1, and can be driven by a drilling machine driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com