A method for forming low-strength thick plate fine-blanking parts with countersunk holes and slender blind holes

A low-strength, fine-blanking technology, which is applied in the field of parts processing, can solve the problems of high precision requirements for the position of slender blind holes, easy bruising at sharp edges, and low strength of parts, so as to achieve good application prospects, avoid drill vibration, and drill The effect of high hole accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

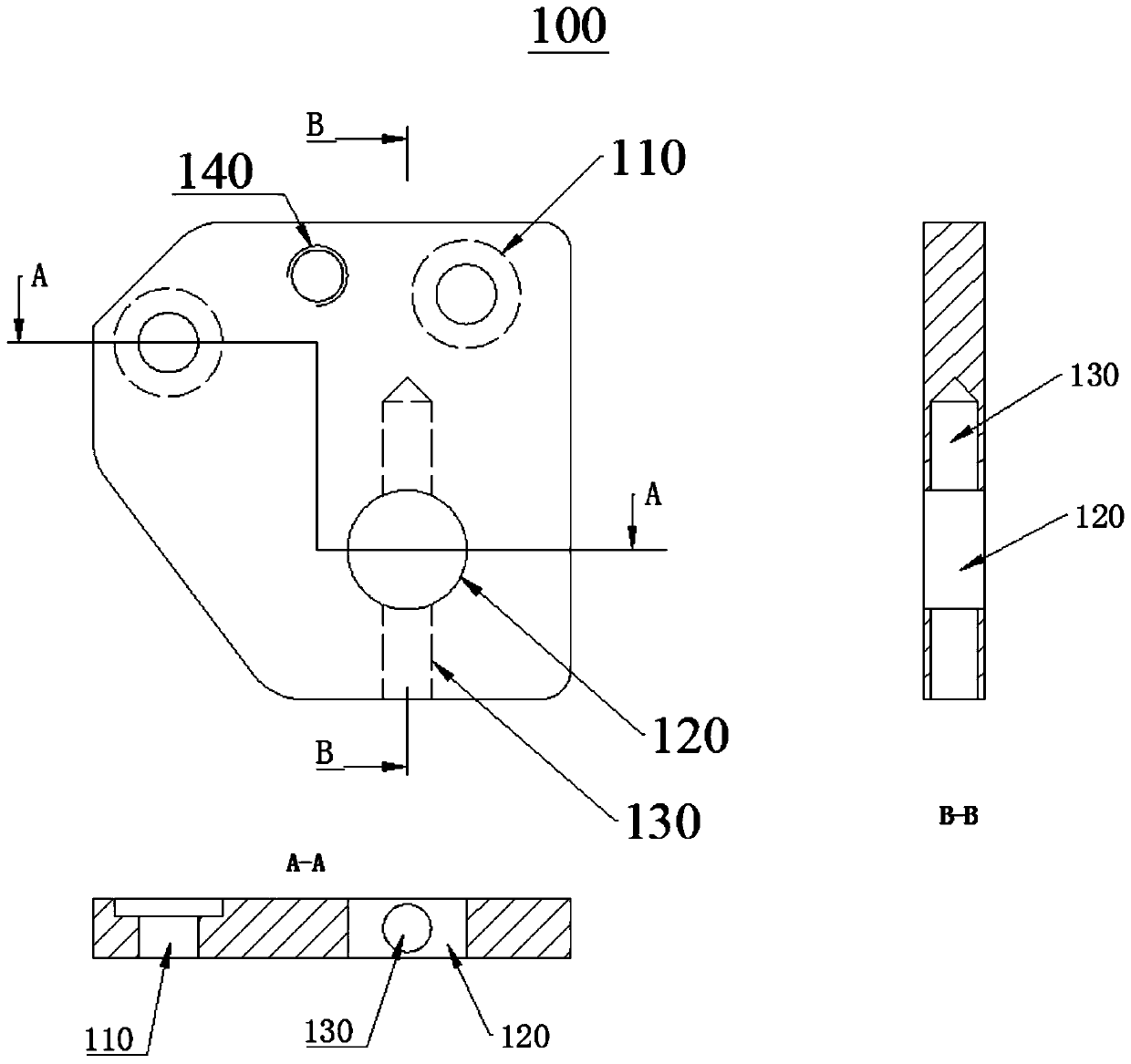

[0047] Such as figure 1 As shown, it is a low-strength thick plate fine blanking part 100 in the embodiment of the present invention, with a thickness tolerance of 0.1mm. The material is 10# hot-rolled steel plate after spheroidizing annealing, and the tensile strength is about 420MPa. The part includes two counterbores 110 (depth 3mm), a large circular hole 120, and a side hole (slender blind hole 130). The axis of the side hole intersects the axis of the large circular hole 120. 50mm, the position requirement is Ф0.2mm.

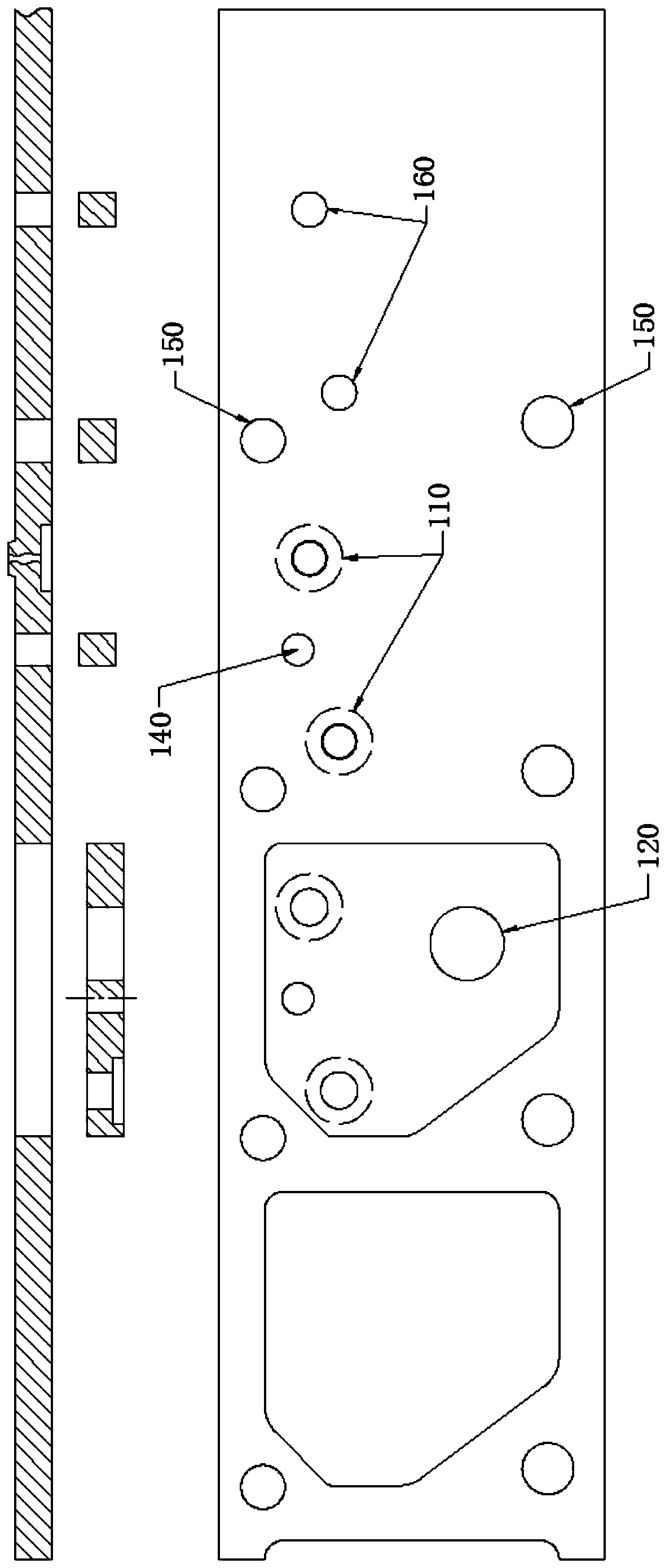

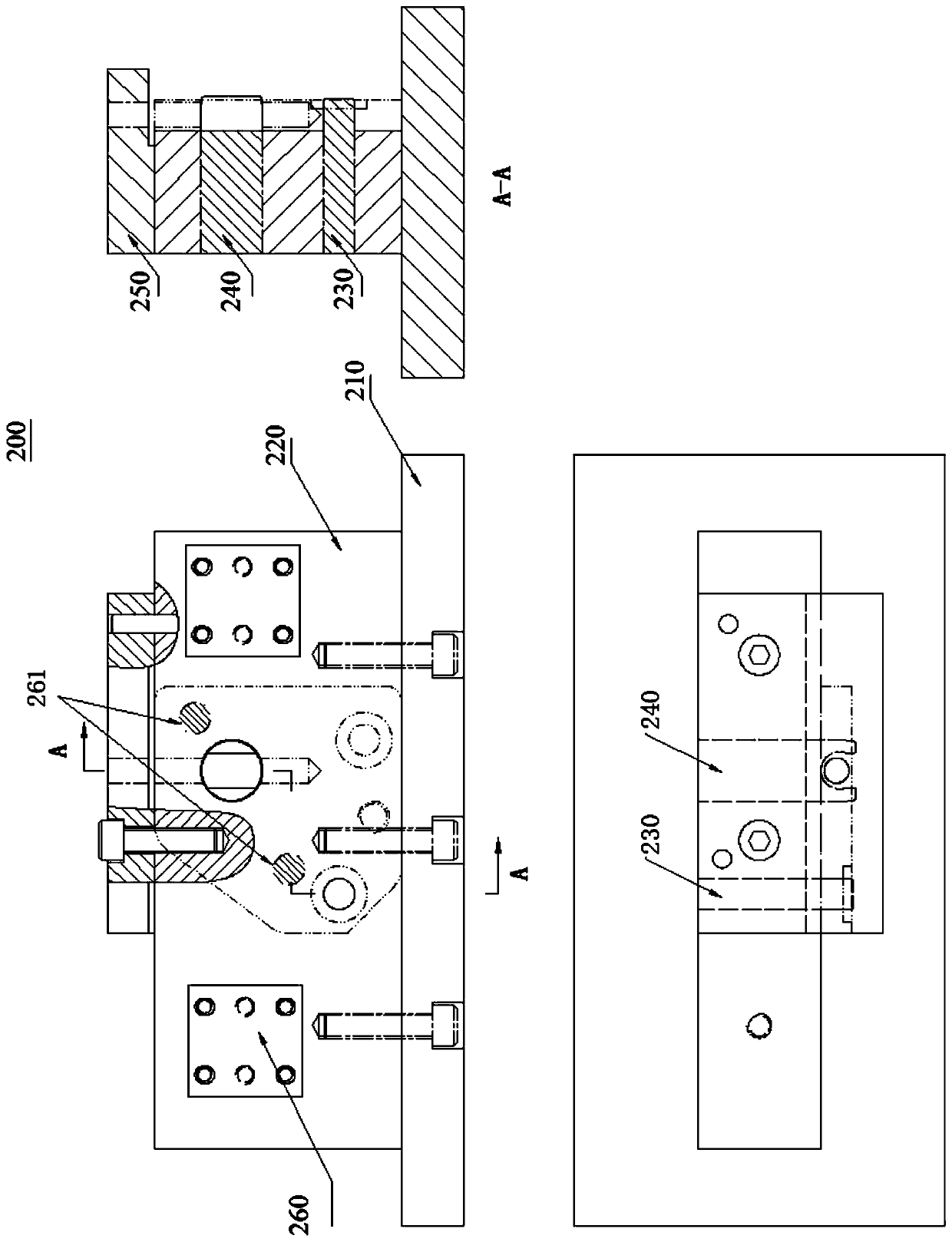

[0048] The present invention proposes the forming method of the above-mentioned low-strength thick plate fine-blanking part with counterbore and slender blind hole, including the following four ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com