Aluminium compoiste material for drilling lubrication

A composite material, aluminum technology, used in circuit substrate materials, polyether coatings, coatings, etc., can solve the problems of complex process, slow production speed, insufficient drilling stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

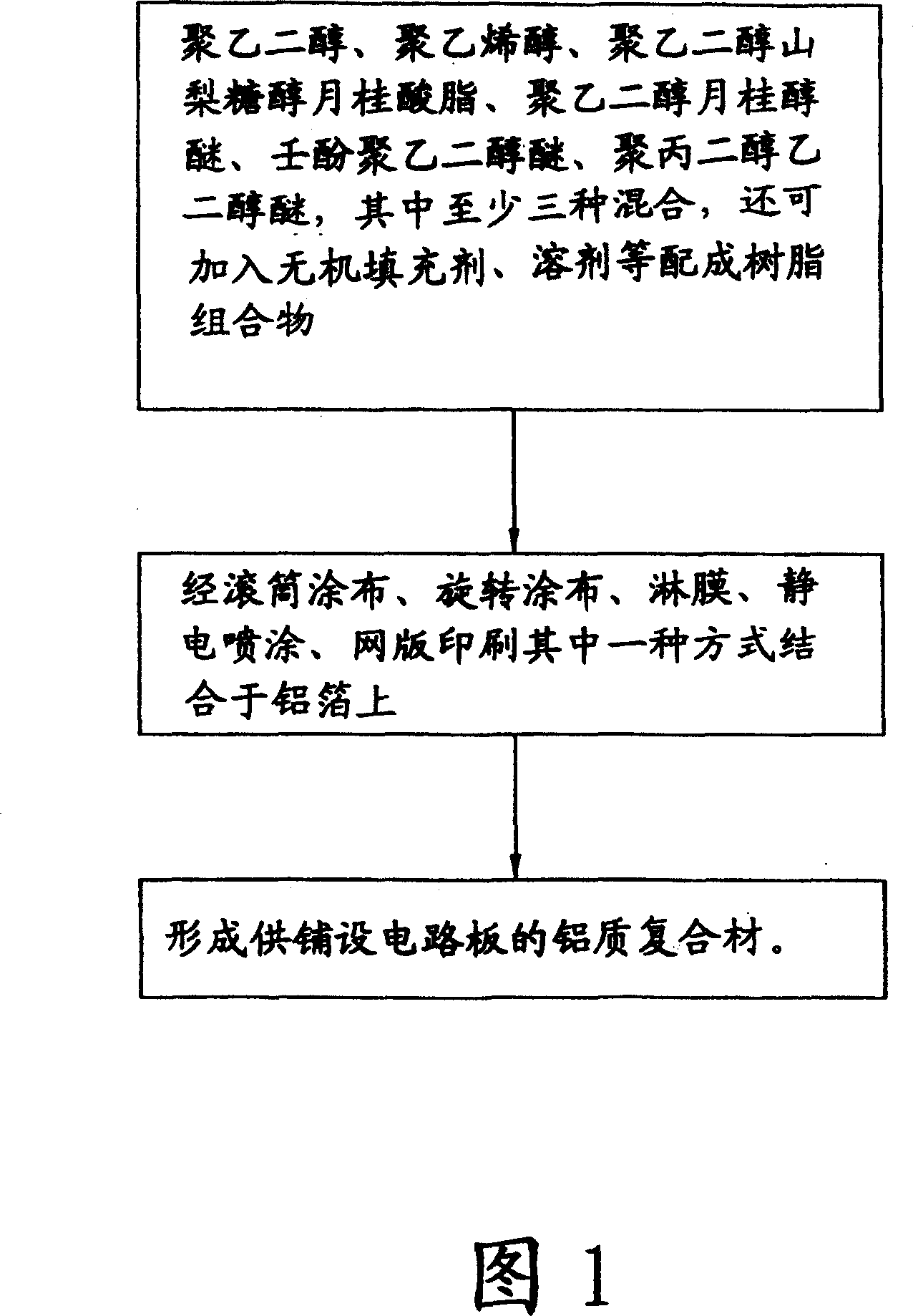

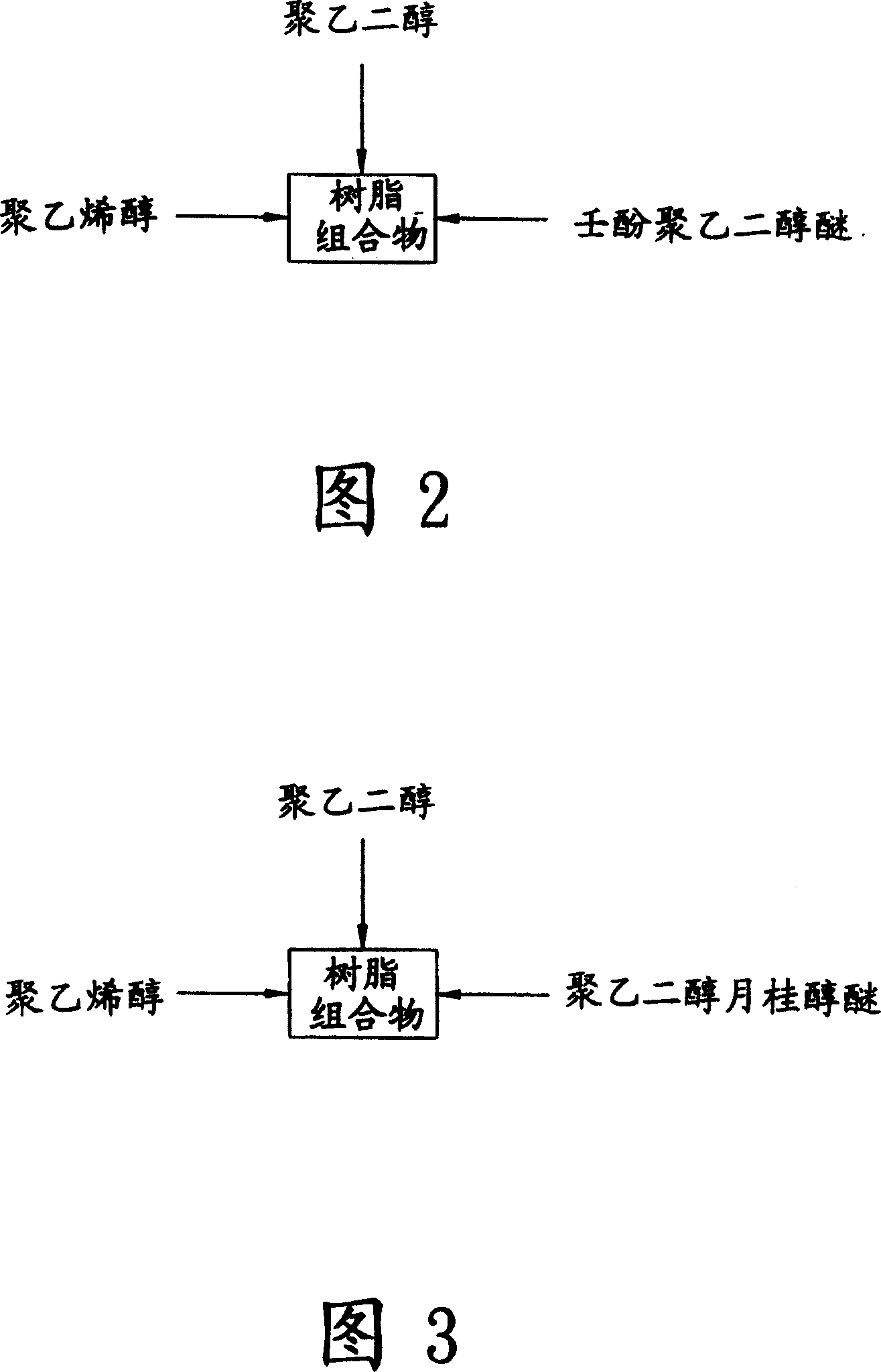

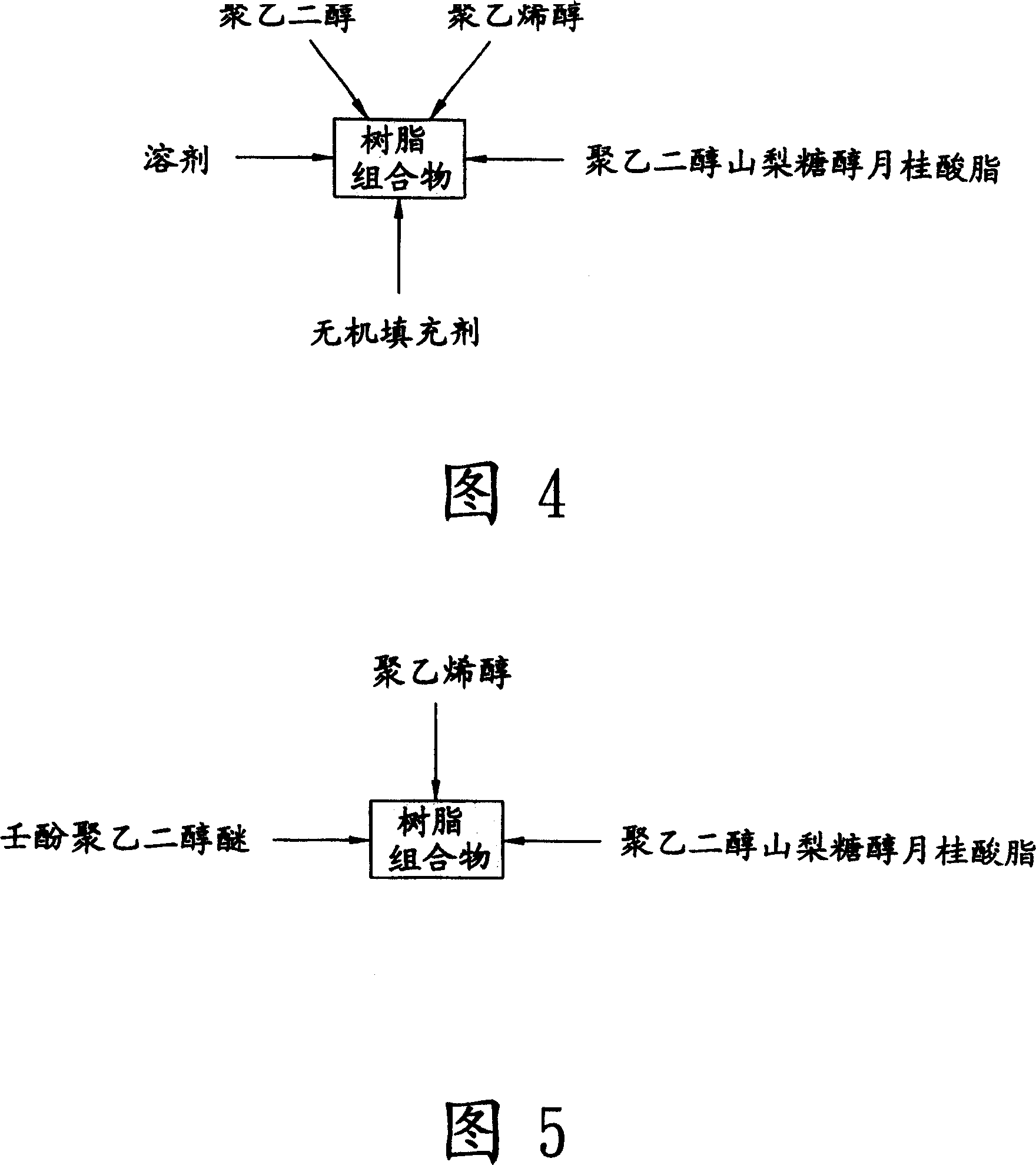

[0017] The present invention is a drilling lubricating aluminum composite material, comprising a resin composition and an aluminum foil, characterized in that: the resin composition is polyethylene glycol (PEG), polyvinyl alcohol (PVA), polyethylene glycol sorbitol Polyoxyethylene sorbitan fatty acid ester, cocount alcohol polyethylene glycol ether, nonyl phenol polyethylene glycol ether, polypropylene glycol glycol ether ( polyoxypropylene, polyoxyethylene ether) at least three optional mixtures, and can also be prepared by adding inorganic fillers, solvents, etc.

[0018] Wherein the inorganic filler is silicon dioxide (SiO 2 ), aluminum hydroxide (Al(OH) 3 ), alumina (Al 2 o 3 ), titanium dioxide (TiO 2 ), calcium carbonate (CaCO 3 ) one of them; and the solvent can be water (H 2 O), Methanol (CH 3 OH), ethanol (C 2 h 5 OH), acetone (C 3 h 7 O) One of them.

[0019] In this way, as shown in Figure 1, when one of the above mixed resins is combined on the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com