Apparatus for preparing macromolecule nano-fibre and spinning method thereof

A nanofiber and polymer technology, applied in fiber processing, temperature control, filament/thread forming, etc., can solve the problem that the local temperature adjustment of the spinneret and nozzle is not fine enough, the heating device cannot be fully utilized, and the temperature regulation is slow and other problems, to achieve the effect of simple and practical operation steps, simple and practical device, and fine adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

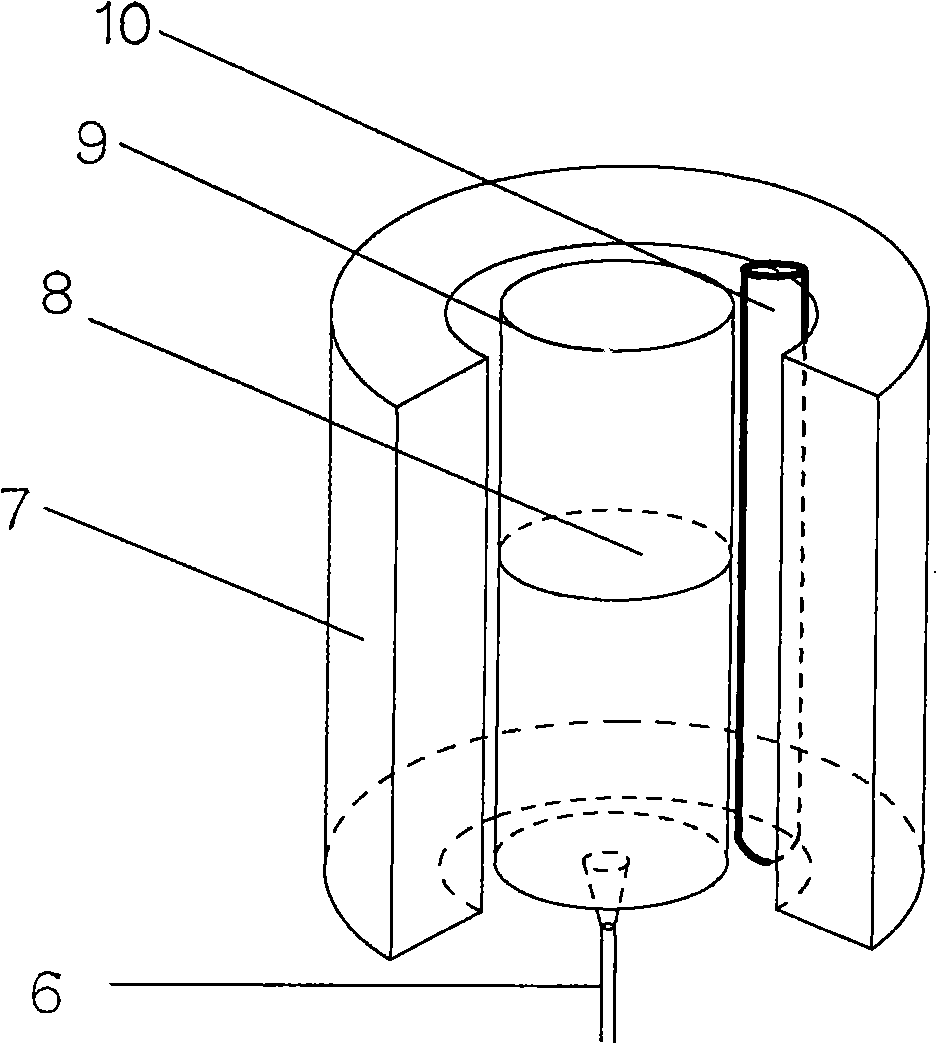

[0034] refer to figure 2 , making the local heating and temperature detection part 3 in the device for preparing polymer nanofibers of the present invention, the local heating and temperature detection part 3 has a spinneret 9 for containing the polymer solution 8, the spinneret 9 is made of glass tube, at the end of the spinneret 9, a conductive metal needle with a ground needle is installed as the nozzle 6, such as a stainless steel injection needle; 9, and close to the outer wall of the spinneret 9, a standard thermocouple temperature sensor 4 purchased on the market with a temperature control error of ±1°C is placed between the spinneret 9 and the heating coil 7 to detect the temperature , the temperature control range of the temperature sensor 4 is 30-300°C.

Embodiment 2

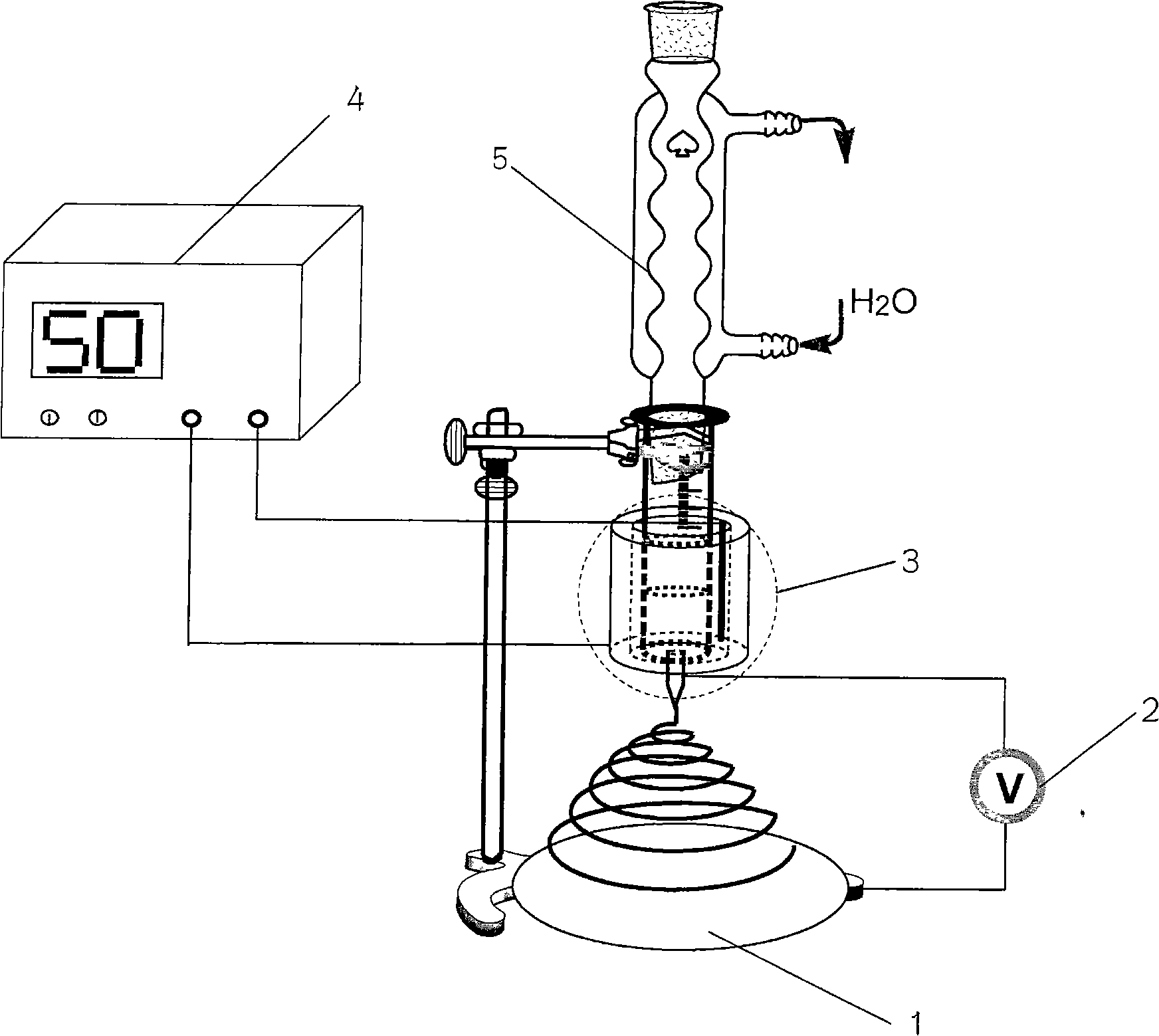

[0036] refer to figure 1 with figure 2 , use the local heating and temperature detection part 3 made in Example 1 to make a set of finely adjustable local temperature electrospinning device of the present invention.

[0037] Take an adjustment bracket with a test tube clamp, install a condensation tube 5 in the test tube clamp, set the local heating and temperature detection part 3 under the test tube clamp, and seal the lower opening of the condensation tube 5 to the spinneret The pipe 9 is connected to the mouth and condensed water is passed into it. The spinneret 9 is connected to the positive pole of the high voltage generator 4 as an anode. A piece of aluminum foil is used as a conductive receiving plate 1, and the conductive receiving plate 1 is electrically connected to the negative pole of the high voltage generator 2 as a cathode, and the cathode is grounded at the same time; the nozzle 6 is arranged directly above the conductive receiving plate 1, and the distanc...

Embodiment 3

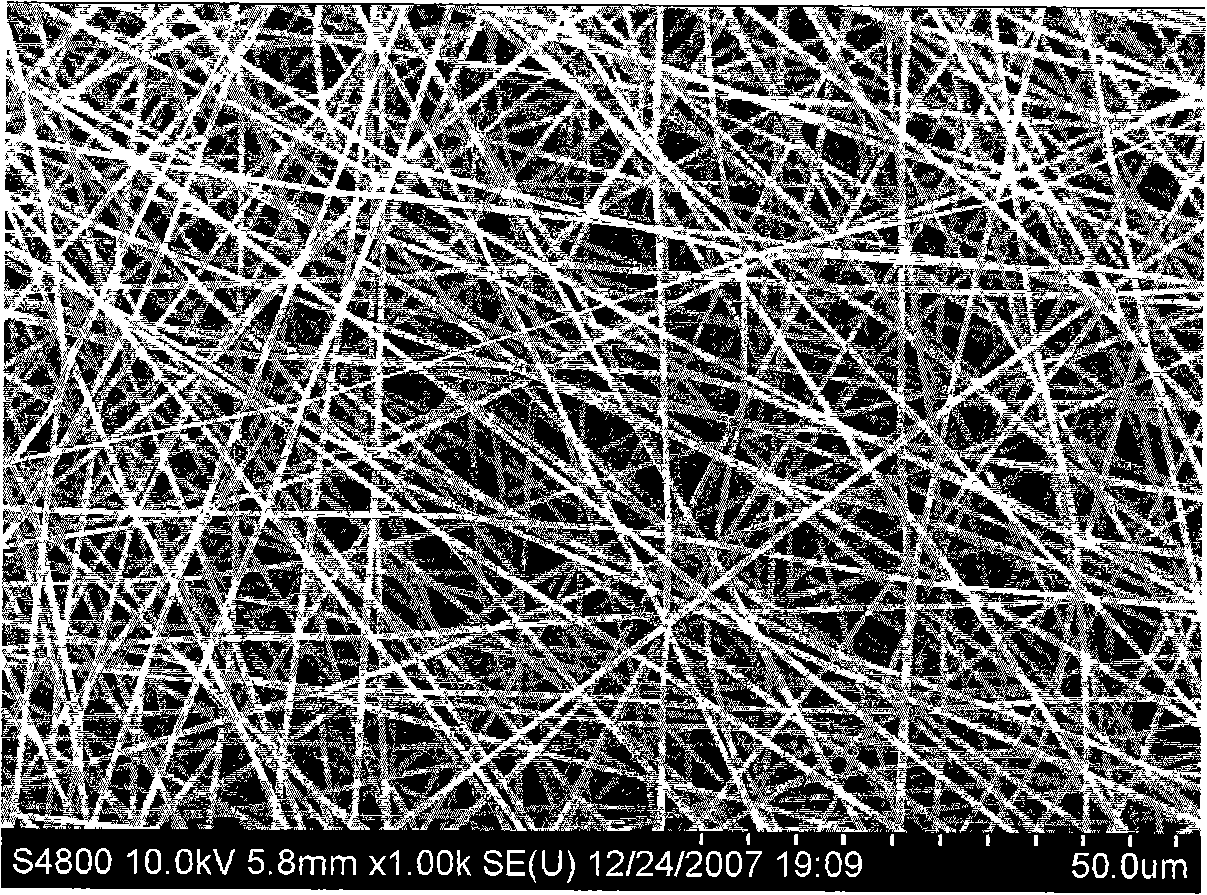

[0040] In this embodiment, the device of Example 2 is used to prepare polyvinylidene fluoride (PVDF) electrospinning by the local fine temperature control method of the present invention, and the specific steps are as follows:

[0041] 1). Dissolve 2g of polyvinylidene fluoride (average molecular weight 270,000) in 8g of a mixed solvent of acetone and dimethylformamide (DMF), heat to 70 degrees Celsius, and magnetically stir for 4 hours to obtain the concentration at 70 degrees Celsius. 20wt% transparent PVDF polymer solution 8;

[0042] 2). Start the local heating and temperature detection part 3 in the device, and heat the temperature of this part to the temperature required for the preset PVDF polymer solution spinning, that is, the local heating and temperature detection in Example 1 Part 3 preset temperature is set to 70 degrees Celsius;

[0043] 3). When the electrospinning is prepared by local fine temperature control, when the actual temperature of the local heating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com