Liquid resin composition for electronic parts and electronic parts device

A technology for electronic parts and liquid resin, applied in the field of electronic parts and devices, can solve problems such as difficult and effective correspondence, and achieve the effects of high industrial value, good migration resistance and excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

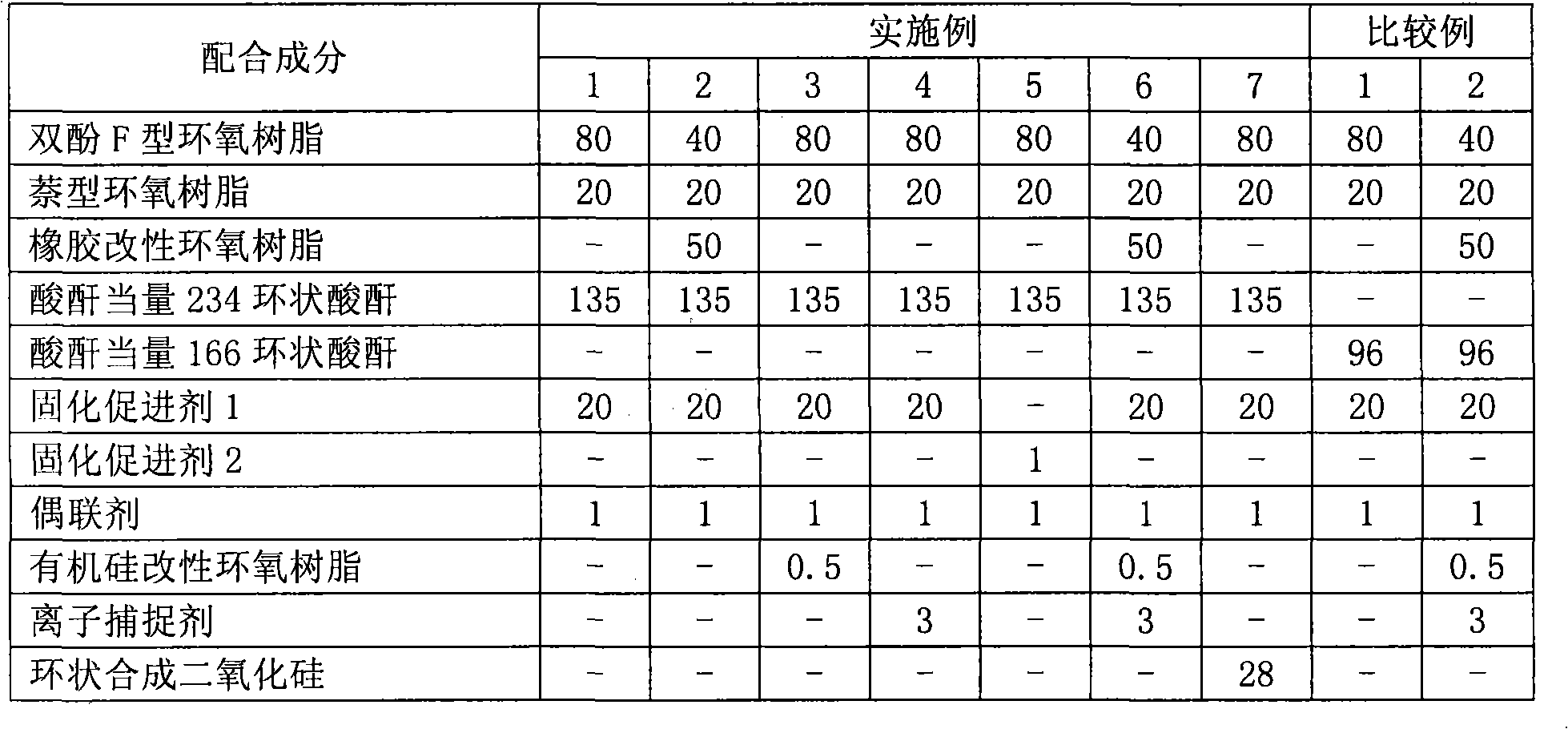

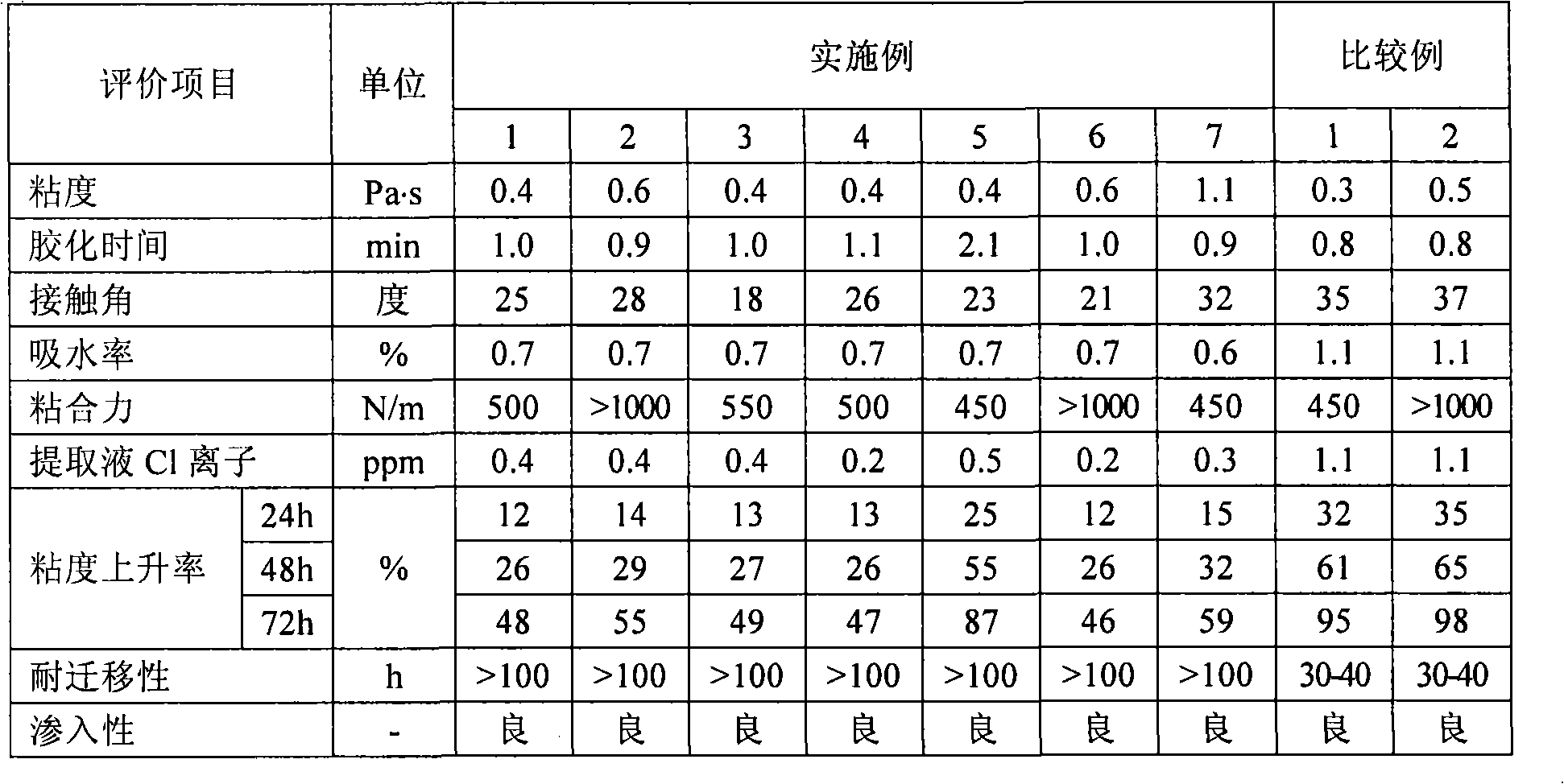

Embodiment 1~7 and comparative example 1~2

[0066] Prepare (A) epoxy resin: bisphenol F type liquid epoxy resin (made by Dongdu Chemical Co., Ltd., trade name YDF-8170C) with epoxy group equivalent of 160, naphthalene type epoxy resin with epoxy group equivalent of 140 (big Japan Ink Industry Co., Ltd. product name HP-4032),

[0067] (B) Cyclic acid anhydride: a cyclic acid anhydride (trade name jER CureYH306 manufactured by Japan Epoxy Resin Co., Ltd., manufactured by Japan Epoxy Resin Co., Ltd.) that is liquid at room temperature and has an anhydride equivalent of 234. Comparative curing agent: a cyclic acid anhydride that is liquid at room temperature and has an acid anhydride equivalent of 166. Acid anhydride (trade name HN-2200 manufactured by Hitachi Chemical Industry Co., Ltd.).

[0068] Prepare latent curing accelerator: disperse microencapsulated amine in bisphenol A type epoxy resin, bisphenol F type epoxy resin curing accelerator (Asahi Kasei Chemical Co., Ltd. registered trademark Novacure HX-3921HP, curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com