Nanometer metal pipe and nanometer preparation method thereof

A metal tube and nanotechnology technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem that the material cannot be uniformly nanosized and repeatable, the inner surface of the metal pipe is not suitable for nanometering, and special specifications cannot be prepared. products, etc., to achieve strong adaptability, uniform and stable nano-layers, and achieve large-scale effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

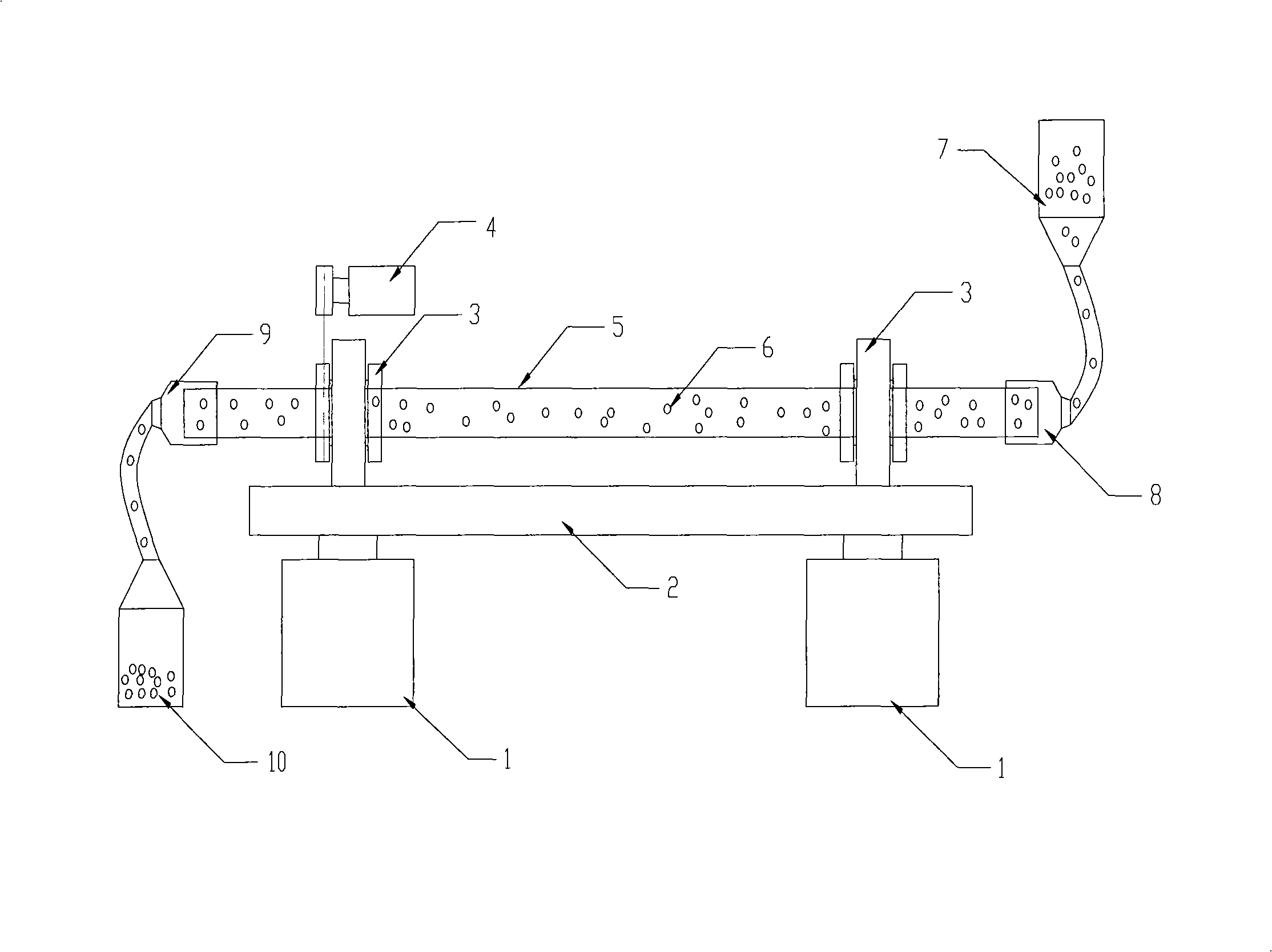

Image

Examples

Embodiment 1

[0067] The inner diameter of the aluminum tube is 15mm, the outer diameter is 25mm, the length of the metal tube is 1.0m, and the metal tube is placed horizontally. The number is 10r / min, and the surface is nano-sized after 15min. The XRD analysis shows that the inner wall of the aluminum tube has been nanosized, and the size of the nanocrystals is about 15nm. The nanonization depth is 50 μm.

Embodiment 2

[0069] The inner diameter of the magnesium-aluminum alloy tube is 30mm, the outer diameter is 40mm, the length of the metal tube is 200mm, and the metal tube is placed horizontally. The speed is 12r / min, and the surface is nano-sized after 25min. The XRD analysis shows that the inner wall of the magnesium-aluminum alloy tube has been nano-sized, and the size of the nano-crystal is about 10nm. The nanometerization depth is 40 μm.

Embodiment 3

[0071] The inner diameter of the copper tube is 40mm, the outer diameter is 55mm, the length of the tube is 3.0m, the metal tube is placed horizontally, the diameter of the ceramic ball is 8mm, and the number of the ball is 1 / 3 of the inner volume of the tube. The oscillation frequency is 100Hz, the amplitude is 50mm, the rotation speed of the aluminum tube is 25r / min, and the surface is nano-treated for 30min. The XRD analysis shows that the inner wall of the copper tube has been nano-sized, and the size of the nano-crystal is about 40nm. The nanometerization depth is 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com