Single-crystal furnace guide shell and production process thereof

A production process and guide tube technology, applied in the field of single crystal furnace guide tube and its production process, can solve the problems of low strength of graphite products, many consumables, poor thermal shock resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

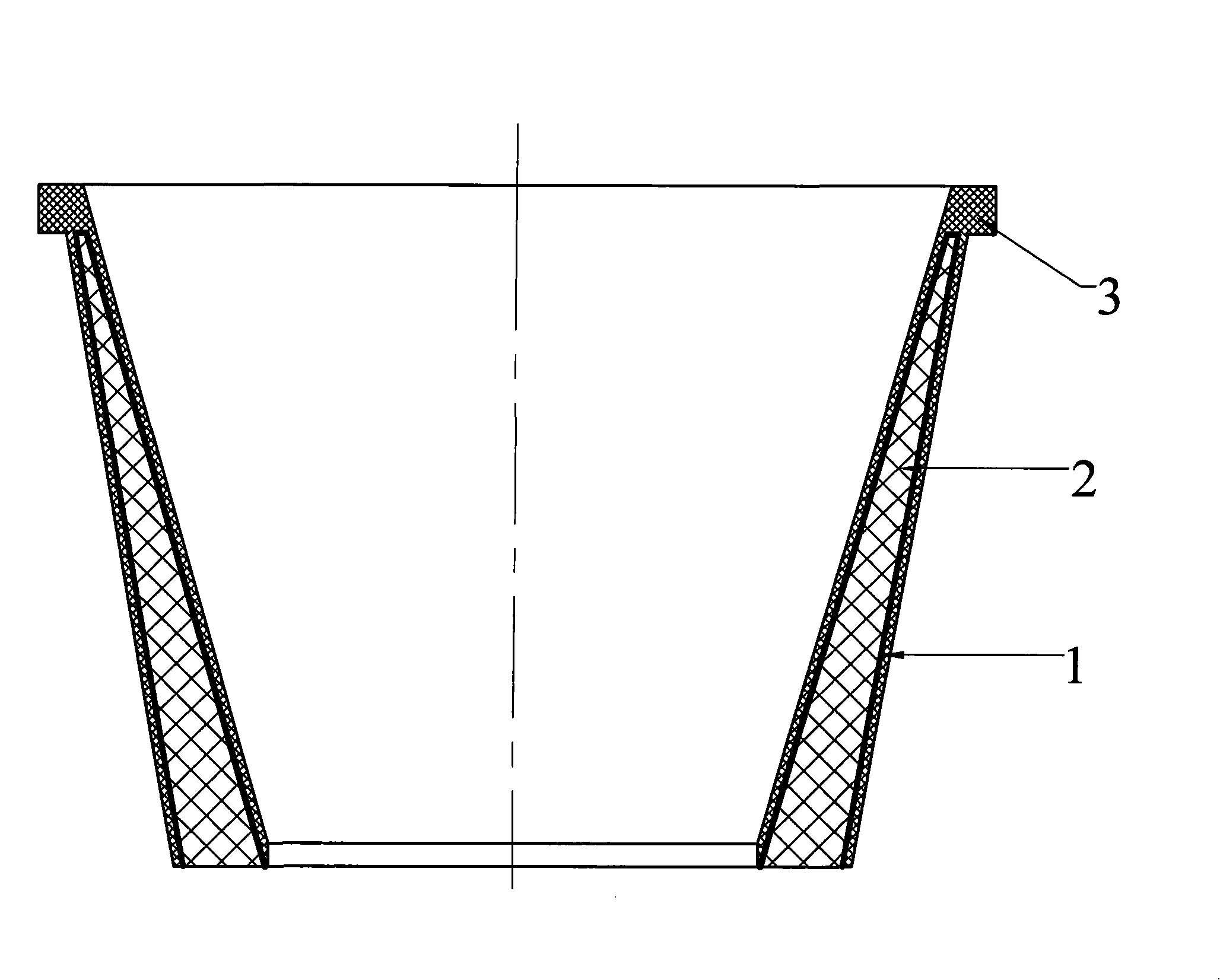

[0020] It can be seen from the accompanying drawings that a single crystal furnace guide tube is made of carbon / carbon composite material.

[0021] A single crystal furnace guide tube is made of carbon fiber through billet making-densification-purification-machining.

[0022] The guide tube of the present invention comprises a surface layer 3 and an inner layer 2, and the apparent density of the surface layer 3 is 1.2g / cm 3 ~1.7g / cm 3 (the present embodiment is 1.3g / cm 3 ), the apparent density of inner layer 2 is 0.4g / cm 3 ~0.9g / cm 3 (the present embodiment is 0.7g / cm 3 ).

[0023] The production technology of described guide tube, it comprises the following steps:

[0024] (1) Blank making: the net tire made of carbon fiber and carbon cloth are combined into a felt by needle punching, as the surface layer 3, and the net tire as the inner layer 2 is wound layer by l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com