Method for preparing large size hollow ceramic plate and use products thereof

A manufacturing method and ceramic plate technology, applied in ceramic products, applications, combustion methods, etc., can solve the problems of difficult application, cumbersome installation, high cost, etc., and achieve the effect of wide source of raw materials and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

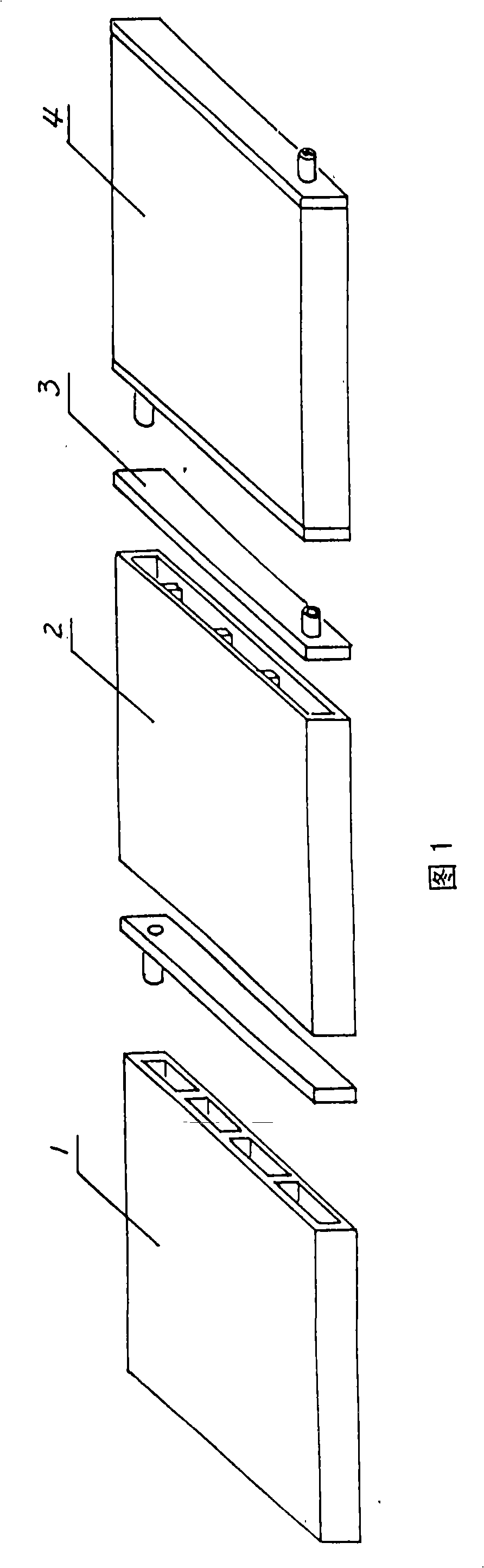

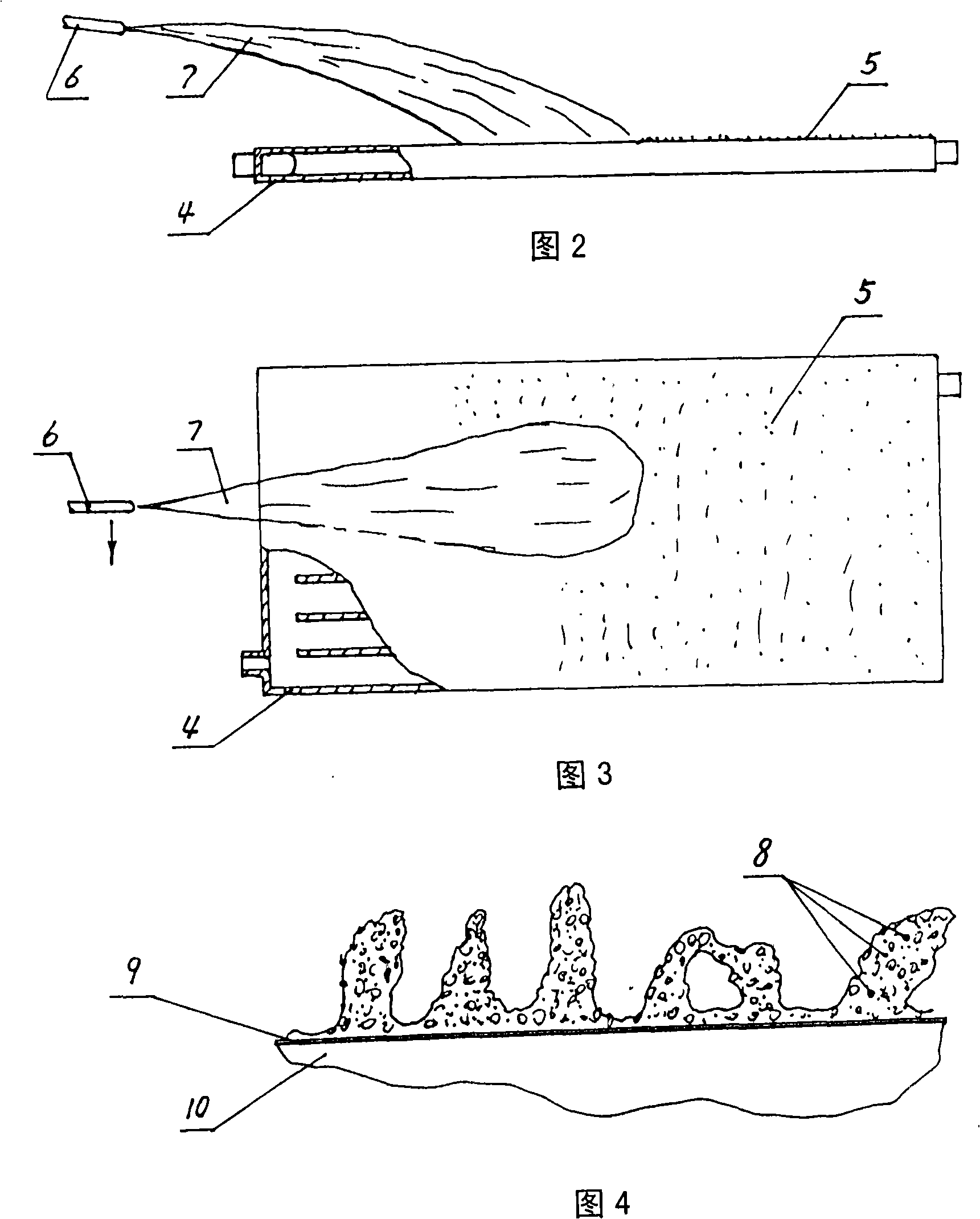

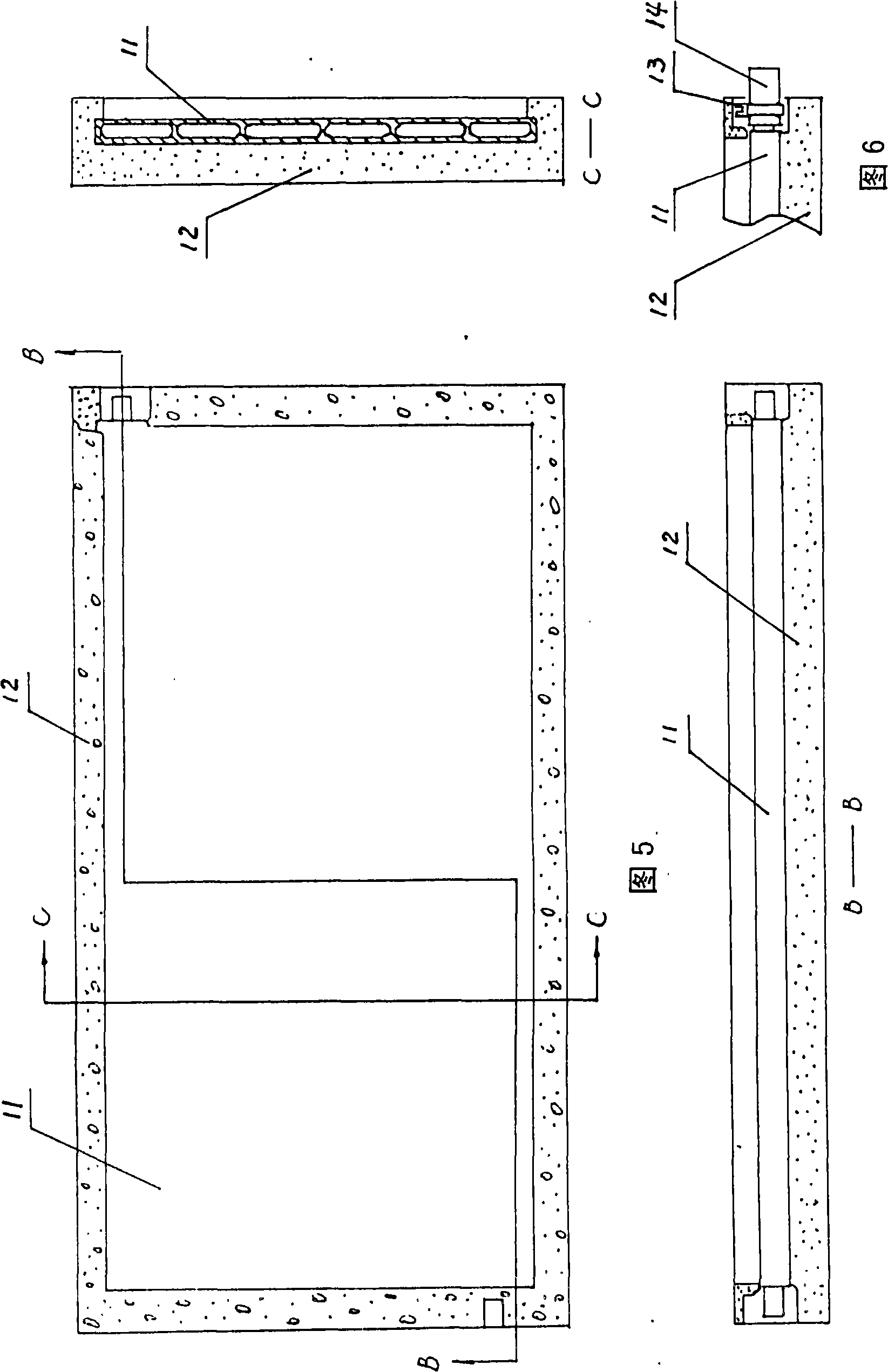

[0089] 1. Common ceramic raw materials clay, quartz, feldspar and water are added to make mud. After sieving, it is press-filtered into mud with a water content of 18%. After rough refining and vacuum refining, the mud becomes a mud section, which is extruded by a vacuum extruder. A perforated plate blank with a width of 700mm, a total thickness of 30mm, 21 holes, a wall thickness of 3mm, and a length of 1150mm is produced, and the partial partition walls at both ends of the perforated plate are removed to form a through-hole plate blank with both ends of the through holes connected. Use mud to bond the end plate with the inlet and outlet nozzles of the same material to become the blank of the sealing plate, which is ready to use after being properly dried. Use 35% of vanadium-titanium magnetite, 30% of manganese ore, and 25% of chromite (weight percentage, below The same), 20% of ordinary ceramic raw materials, are jointly ground into mud, passed through a 200-mesh sieve, spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com