Color fingerprint resistant sheet and process method thereof

A processing method and fingerprint-resistant technology, applied in chemical instruments and methods, hot-dip plating process, metal material coating process, etc., can solve the problems of unable to cover the surface defects of the plate, single surface morphology of the transparent fingerprint-resistant plate, etc., to achieve rich Variety, rich surface morphology, good roughness uniformity

Inactive Publication Date: 2008-11-26

江苏江南精密金属材料有限公司

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is: the problem that the traditional transparent anti-fingerprint plate has a single surface shape and cannot cover the defects on the surface of the plate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

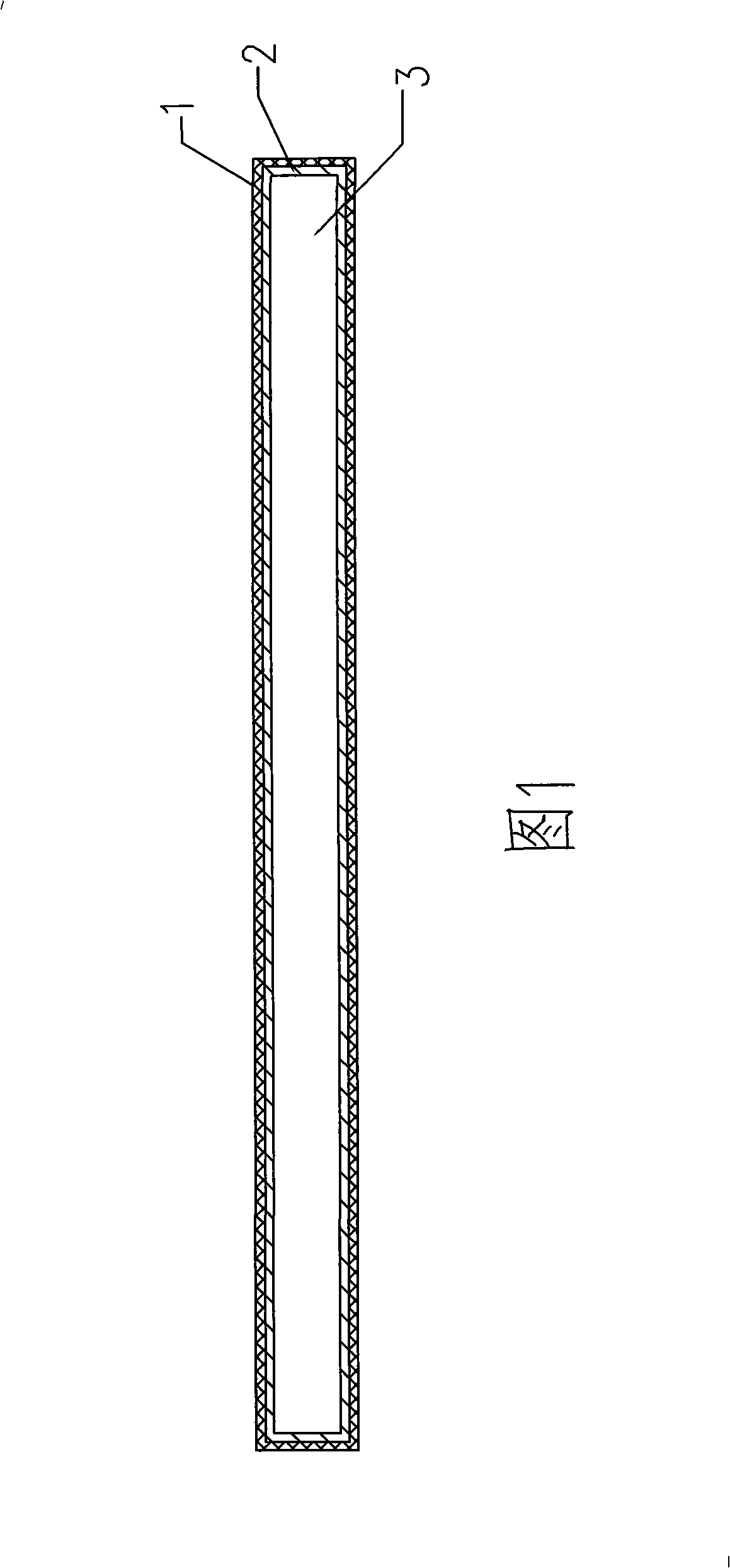

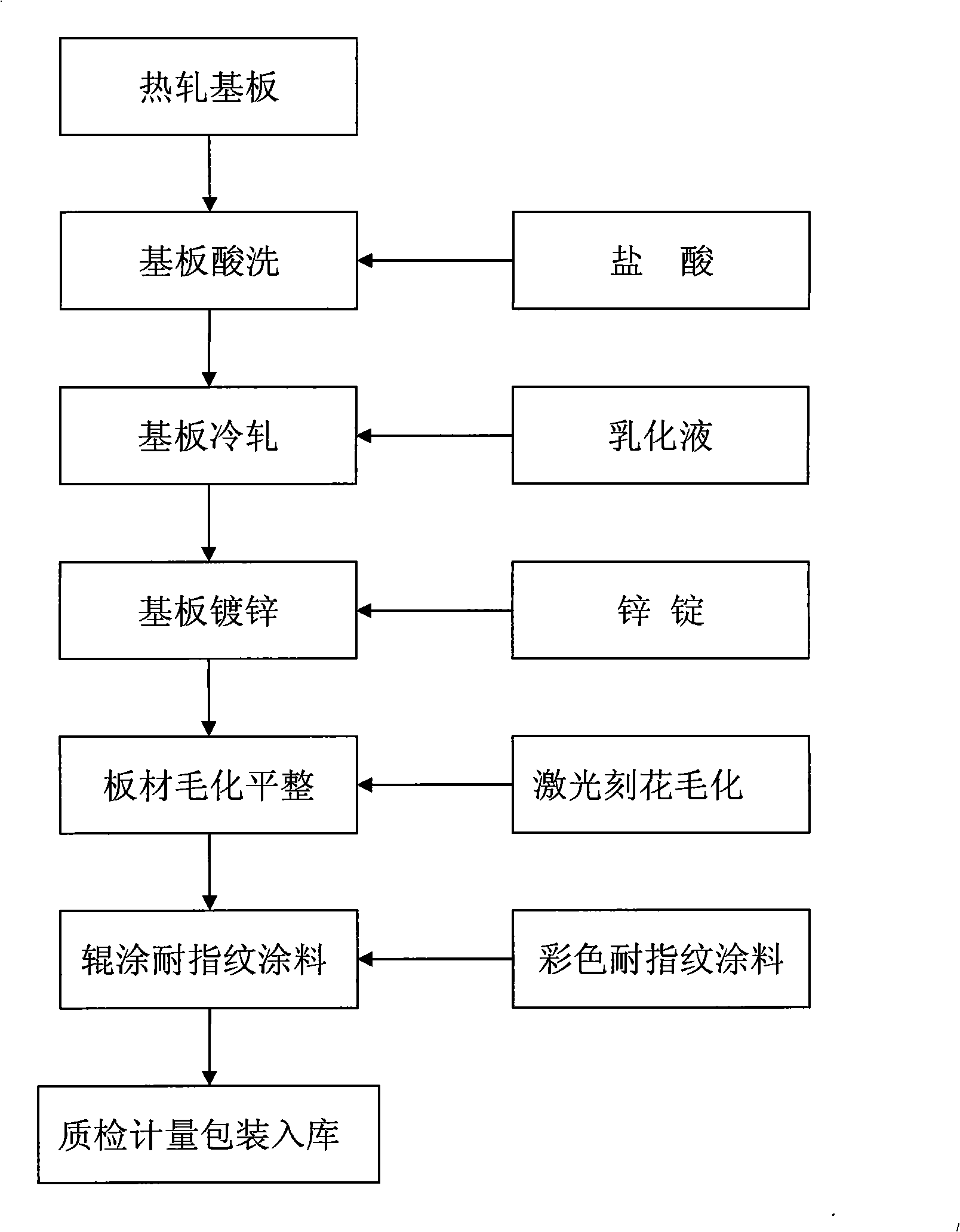

The invention relates to the technical field of the plates of home appliances, in particular to a fingerprint-resistant plate and a processing method thereof. The color fingerprint-resistant plate is provided with a steel plate layer, a zinc coating outside the steel plate layer and a fingerprint-resistant layer outside the zinc coating, wherein, the fingerprint-resistant layer is a non-transparent color coated film. The processing method of the fingerprint-resistant plate includes the following steps: a. the pickling of a basal plate; b. the cold rolling of the basal plate; c. zinc plating of the basal plate; d. the burring and finishing of the plate; e. the roller coating with color fingerprint-resistant coating material. The non-transparent color fingerprint-resistant plate provided by the invention can solve the problems that the surface shape is single and the flaws on the plate surface can not be covered of the traditional fingerprint-resistant plate; in addition, the processing of the invention not only achieves various traditional fingerprint-resistant indexes, but also changes the color of the fingerprint-resistant film, enriches the varieties of zinc-coated products and broadens the application field of the zinc-coated plate.

Description

Color anti-fingerprint plate and processing method thereof technical field The invention relates to the technical field of galvanized sheets for household appliances, in particular to a fingerprint-resistant sheet and a processing method thereof. Background technique In recent years, with the steady and rapid development of my country's national economy, the demand and output of hot-dip galvanized steel sheets have also increased year by year. Moreover, as the world's home appliance manufacturing base, my country's demand for high-grade hot-dip galvanized home appliance panels is also increasing. In 2006, the output of hot-dip galvanized sheets in my country was about 11.7 million tons, of which 2.3 million tons were for home appliances, including 660,000 tons of fingerprint-resistant hot-dip galvanized sheets for home appliances. However, the current domestic production capacity of home appliance panels is only 1.5 million tons, mainly from Baosteel, Wuhan Iron and Steel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B15/08C23C2/26C09D5/16C09D183/00

Inventor 朱翔鹰梅泽锋张志洪

Owner 江苏江南精密金属材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com