Surface roughening treatment method of smooth-contour copper foil

A technology of surface roughening and treatment method, which is applied in the field of smooth contour copper foil surface roughening treatment, which can solve the problems of line floating, insufficient roughness of nodular grains, poor anti-peeling strength, etc., and achieve the effect of eliminating micro-etching effect, good roughness uniformity, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

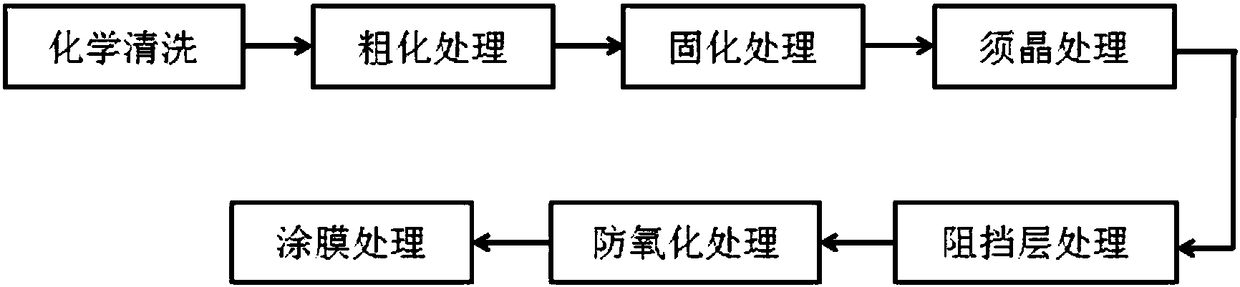

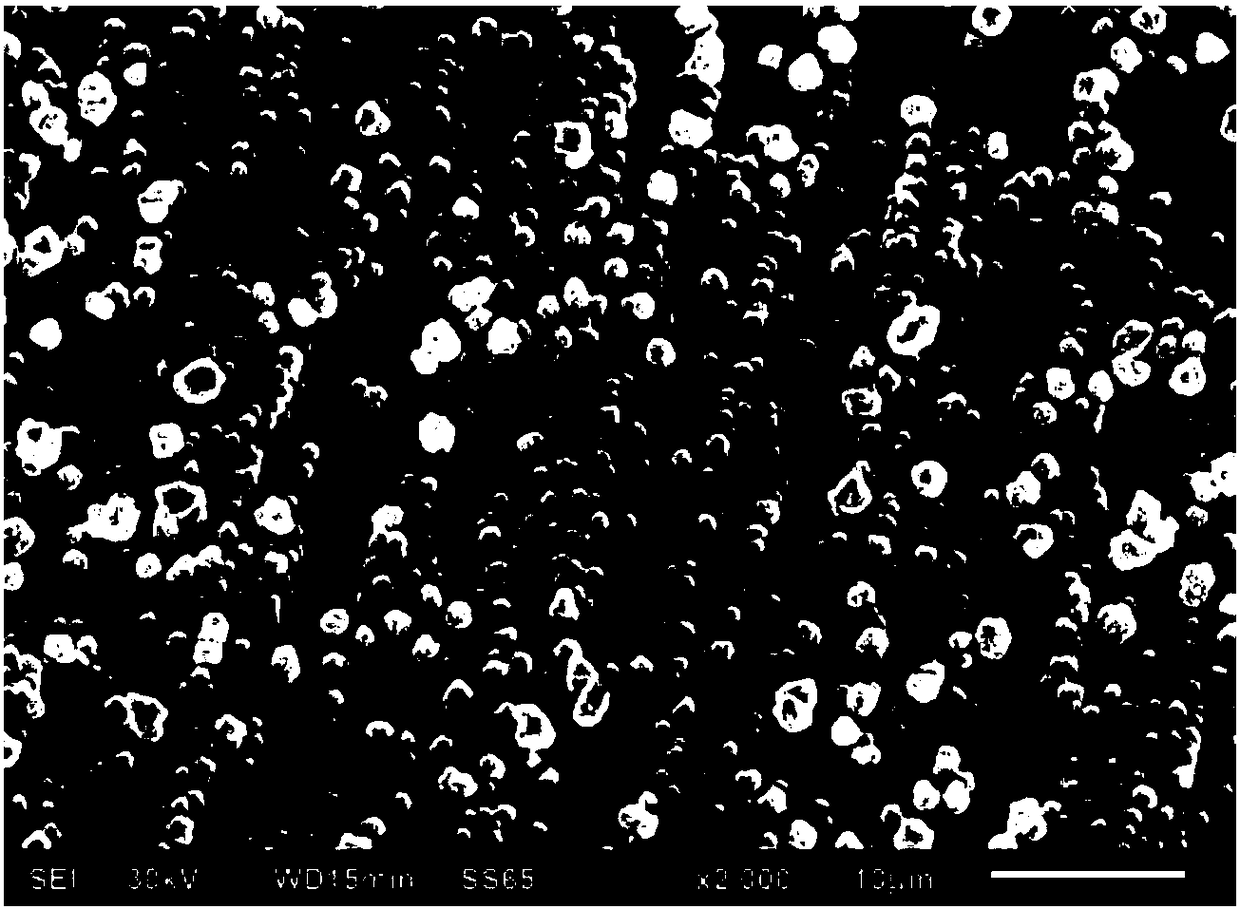

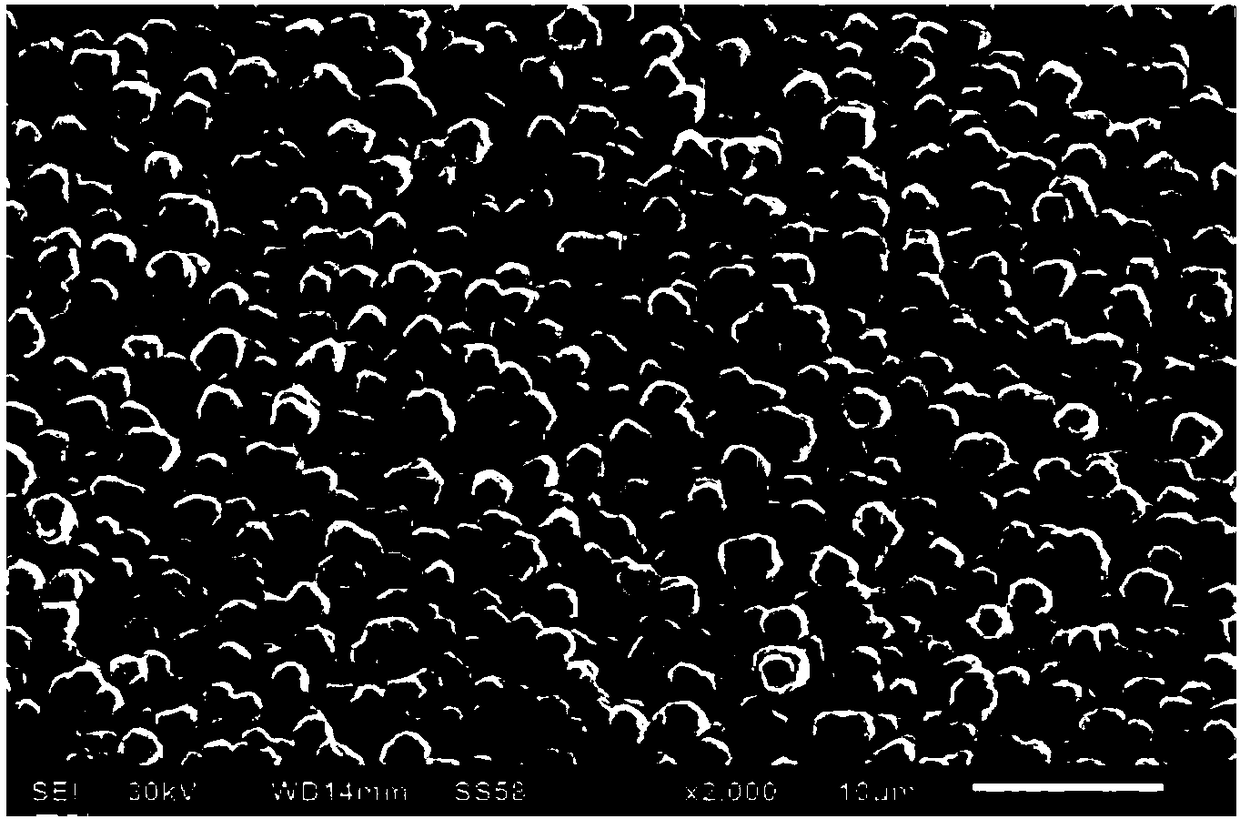

[0029] A method for roughening the surface of smooth contour copper foil and the copper foil for high-speed high-frequency circuits obtained by the method, the method is to roughen the matte surface of copper foil in the roughening stage of the smooth contour copper foil surface treatment process Using copper sulfate electrolyte, uniform nodular crystals are formed on the rough surface of copper foil treated by hydrogen peroxide-sulfuric acid microetching solution; the smooth surface morphology of copper foil treated by hydrogen peroxide-sulfuric acid microetching solution is not affected; the The concentration of the hydrogen peroxide-sulfuric acid microetching solution is 10-50g / L; it includes the following steps: (1) Microetching is reduced to coarsening: spray acidic microetching solution on the rough surface of the copper foil, and microetch the rough surface of the copper foil Subtract and roughen; while performing micro-etching on the rough surface of the copper foil, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com