Control method for electronic ballast of HID light without electrolytic capacitor

A technology of electronic ballast and control method, which is applied to the use of gas discharge lamps, electric light sources, electrical components, etc., can solve problems such as wide application range, inability to use DC power supply, and sensitivity to AC frequency of inductive ballasts, and achieve Effect of Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

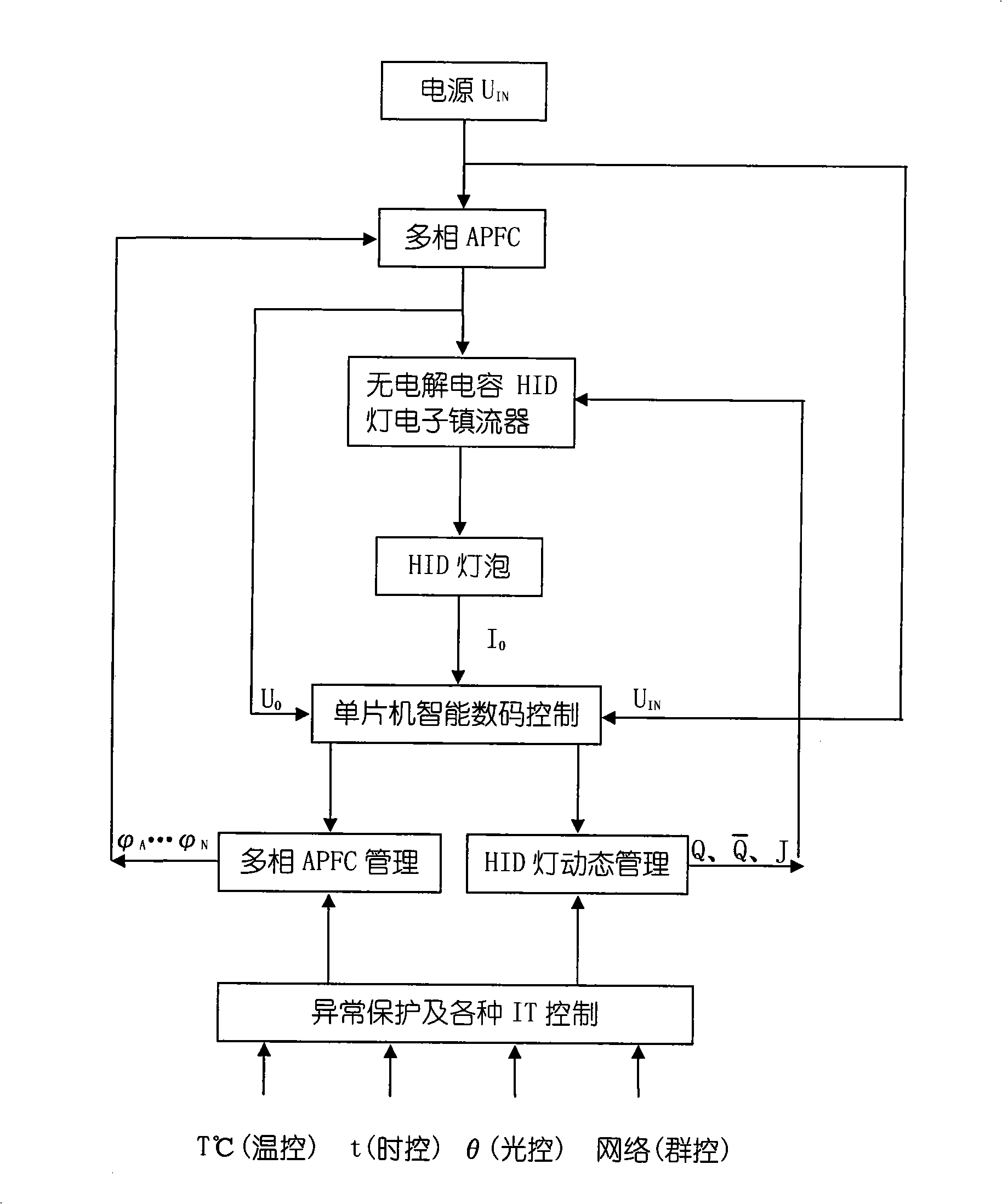

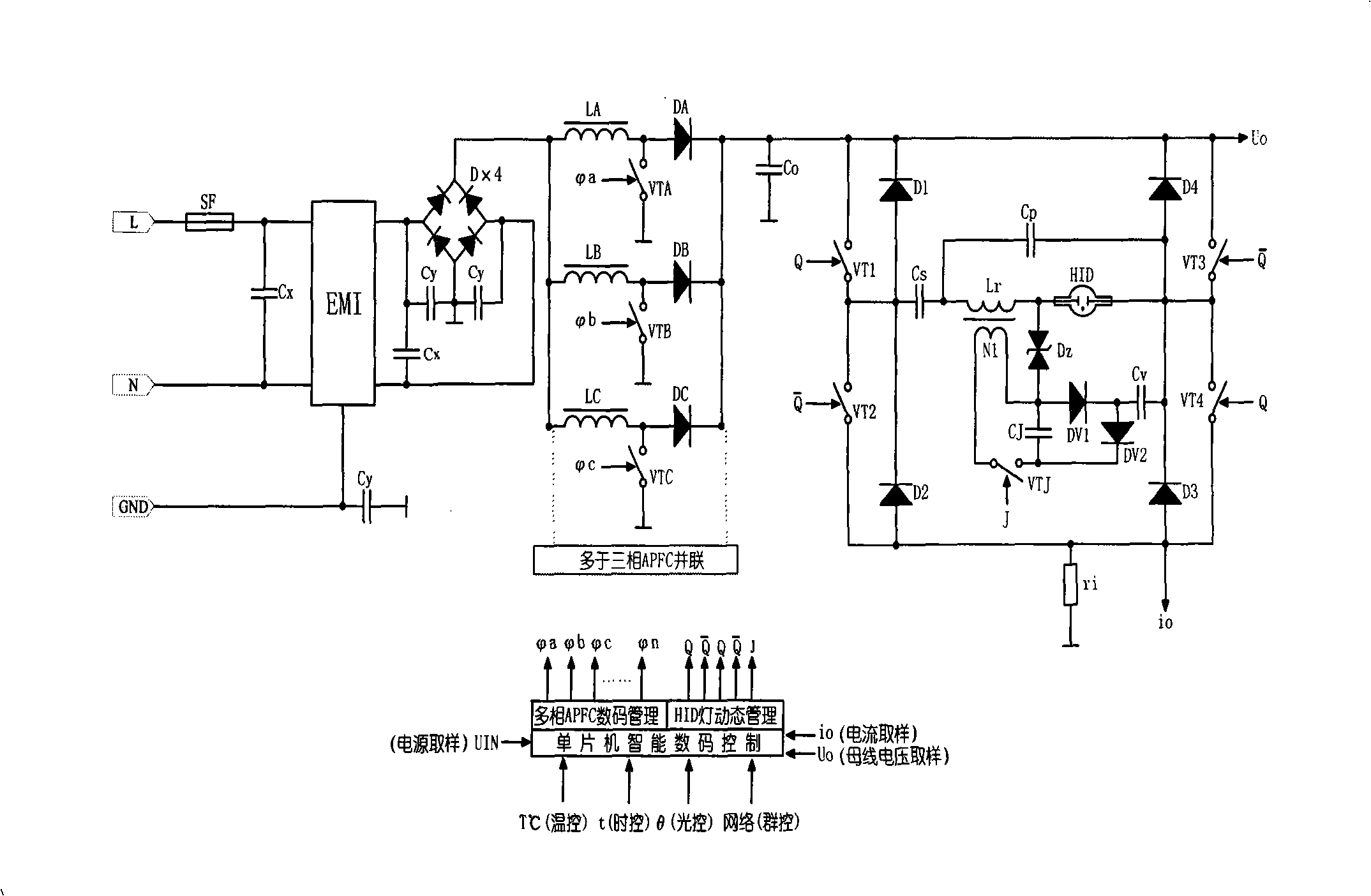

[0018] combine figure 1 The embodiment of the present invention is described as follows:

[0019] Judging from the function of electrolytic capacitors in traditional electronic ballasts for HID lamps with electrolytic capacitors, electrolytic capacitors are the main function, which is to convert the peak value of power + Δu 0 The charge stored in the electrolytic capacitor is called "charging". Then, in the power sag trough -Δu 0 When the charge is released, it is called "discharge"; the electrolytic capacitor uses "charge" to absorb the peak ripple, and uses "discharge" to fill the valley ripple, which plays a role in smoothing the ripple of the DC bus voltage U0.

[0020] The general passive equivalent is to replace the short-life electrolytic capacitor with electrolyte with a micro-method with a long-life capacitor without electrolyte. This equal-capacitance replacement method is the most basic but negative strategy for realizing non-electrolytic capacitors. One, treatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com