Recovering and regenerating method for waste lubrication oil

A technology of waste lubricating oil and re-refining oil, which is applied in the direction of lubricating compositions, etc., which can solve the problems of difficult removal and regeneration, low yield of base oil, high inorganic reagents, etc., to improve the processing capacity and the yield of the device, and the process operation is simple Flexible, less harsh effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

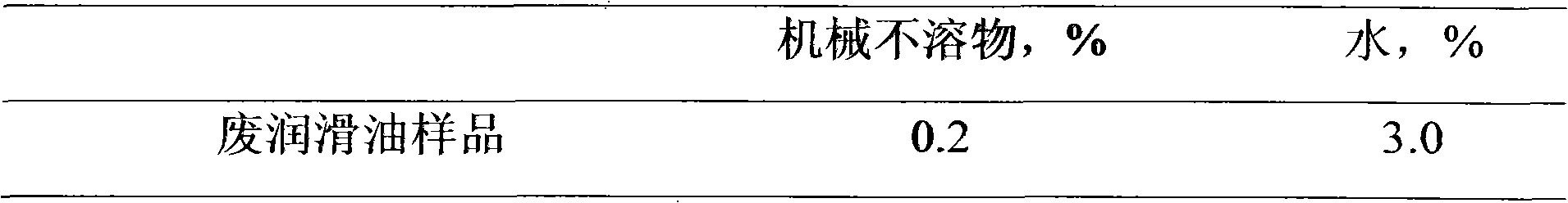

[0025] Take a sample of waste lubricating oil. Considering that this kind of waste lubricating oil may be oxidized, aged, and deteriorated during long-term use, and will produce impurities such as impurities, the mechanical insoluble matter and water content were measured first. The results are shown in the table 1.

[0026] Table 1 Determination of Mechanically Insoluble Matter and Water Content in Waste Lubricating Oil Samples

[0027]

[0028] It can be seen from Table 1 that the mechanically insoluble content of this waste lubricating oil sample is relatively high, reaching 0.2%; the water content is relatively high, reaching 3.0%, which shows that it must be strictly removed before choosing an effective recycling method Mechanical insoluble matter and dehydration treatment.

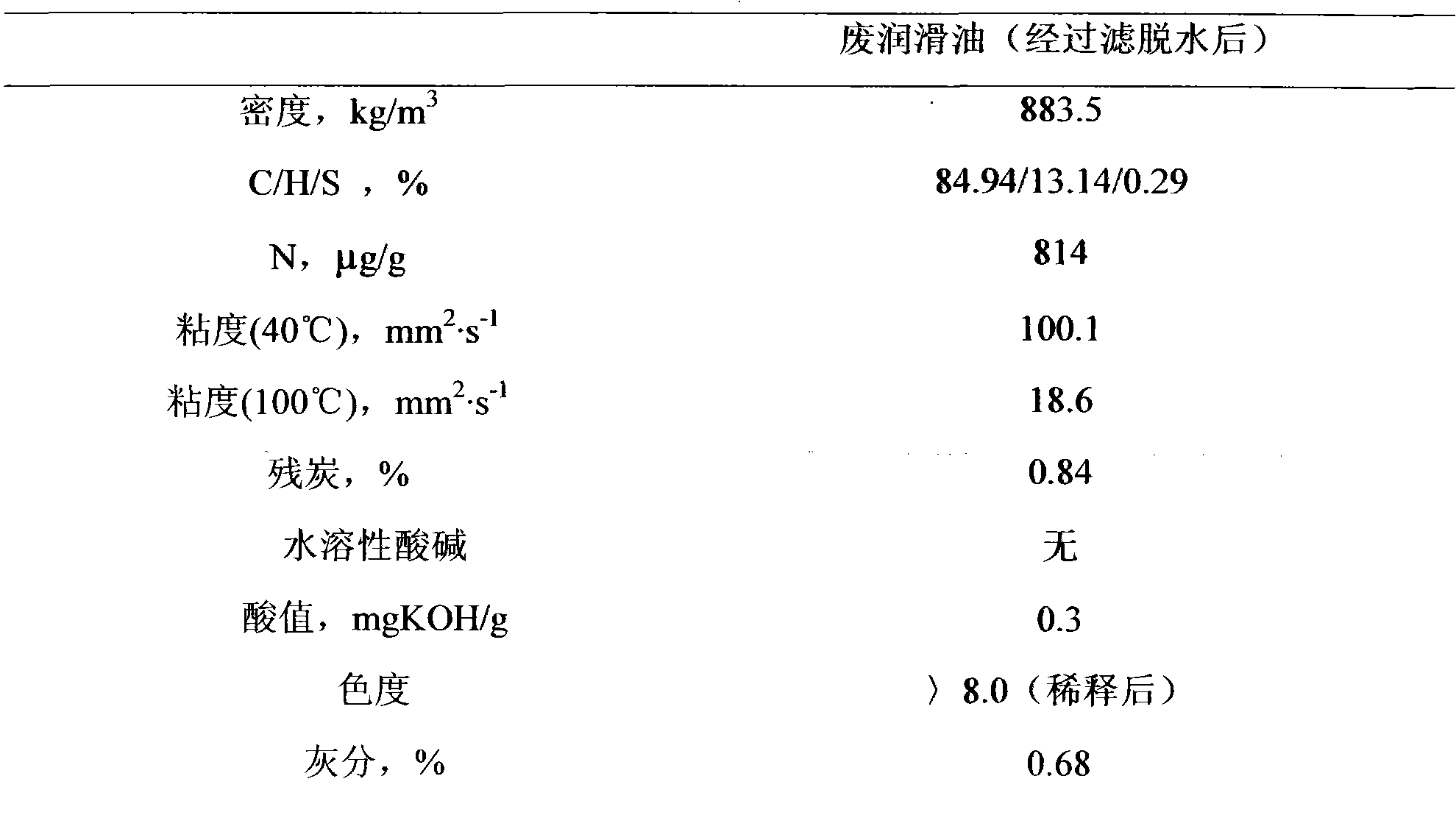

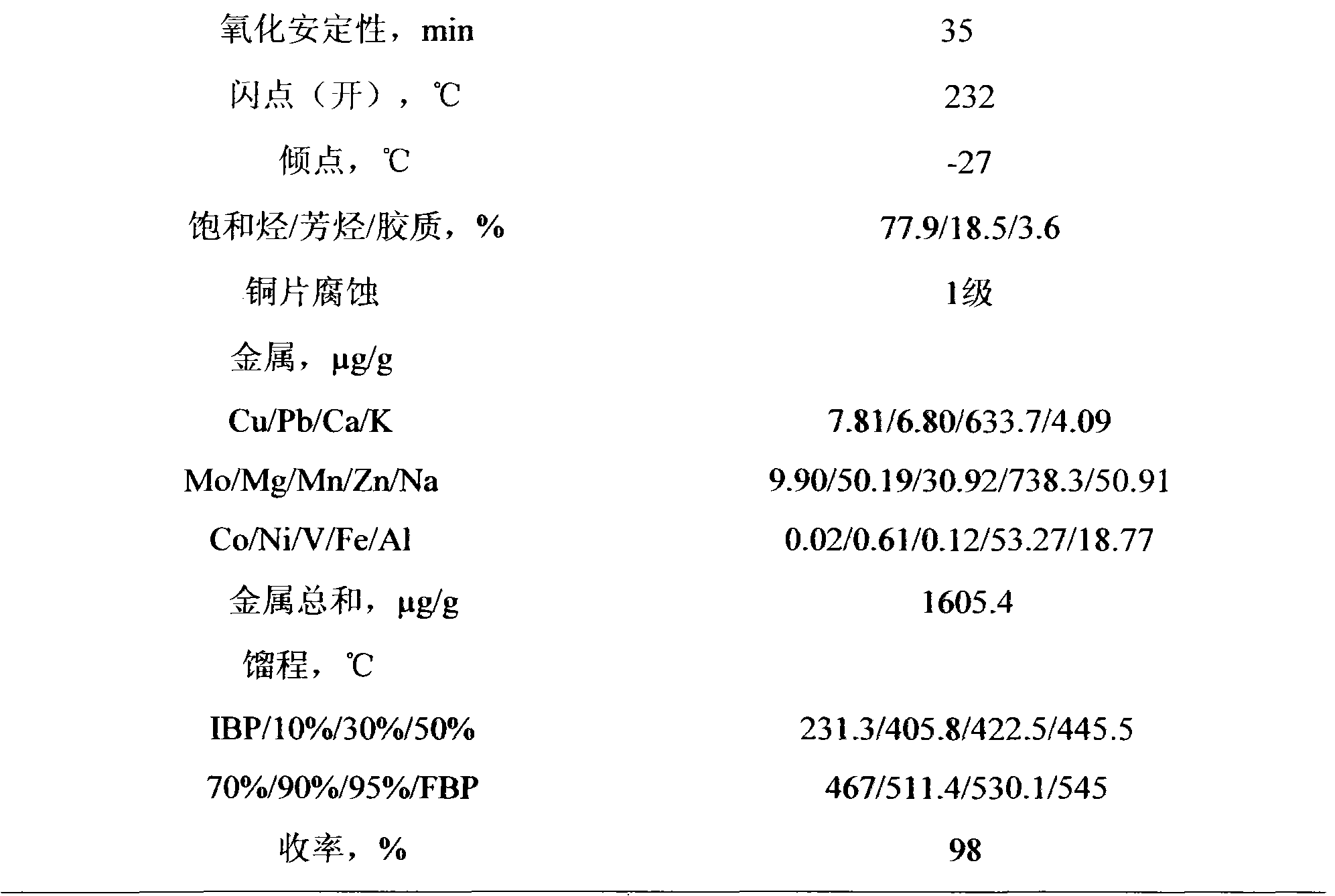

[0029] Using conventional filtration and dehydration operations, most of the mechanical impurities and water were removed, and the properties of the obtained waste lubricating oil are shown in Ta...

Embodiment 2~5

[0035]The content of metal impurities is an important factor affecting the hydrorefining of waste lubricating oil. Through appropriate distillation methods, especially by adding appropriate additives, the metal components can be concentrated in the residue, and the metal content of the obtained lubricating oil base oil is relatively low, which can meet the feed requirements of hydrofining. Example 2 does not use additives, Example 3 uses 2% additives (distillation range greater than 350 ° C catalytic cracking back to refining oil), embodiment 4 uses 5% additives (distillation range greater than 450 ° C catalytic cracking back refining oil), Example 5 uses 8% additives (distillation range greater than 370 ° C coal liquefied oil).

[0036] The sample was distilled, and the impurity content of each fraction after distillation is shown in Table 4.

[0037] Impurity content after table 4 distillation

[0038]

[0039] It can be seen from Table 4 that after proper distillation ...

Embodiment 6~7

[0041] The above-mentioned heavy components were subjected to hydrofinishing, and a hydrofinishing catalyst was used. The performance of the catalyst is shown in Table 6.

[0042] Table 6 Catalyst performance

[0043]

[0044] The specific process is: hydrofining heavy components, pressure 5MPa, temperature 310-320℃, hydrogen-oil ratio 800:1, space velocity 1.0h -1 , process conditions and product property data are shown in Table 7.

[0045] Table 7 process conditions and product properties

[0046]

[0047] It can be seen from Table 7 that the properties of the lubricating base oil after hydrofining treatment are better, all impurities are removed, S and N impurities are basically removed, and important indicators such as chroma, pour point, and flash point also passed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com