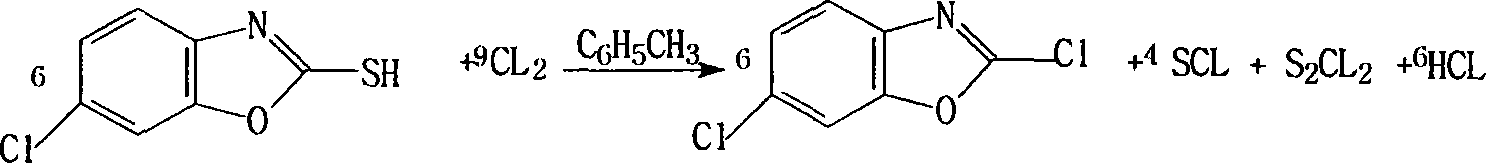

Method for preparing 2,6-dichloro benzoxazole

A technology of dichlorobenzoxazole and mercaptobenzoxazole, applied in directions such as organic chemistry, can solve the problems of producing phosphorus oxychloride by-products, high requirements for high vacuum equipment, and increasing the difficulty of separation, and achieves product yield. High rate, low equipment requirements, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Example 1: Set up a stirrer, thermometer, dropping funnel and condenser in a 500ml reaction vessel, add 150ml of toluene, 50g of 6-chloro-2-mercaptobenzoxazole and 0.8g of dimethylformamide, stir, and heat to 60°C , Trichloromethyl chloroformate was added dropwise, after the addition, the temperature was raised to 80°C for reaction, and after 3 hours, the product was cooled to obtain 152g with a content of 30.3% and a yield of 90.9%.

[0026] Example 2: Set up a stirrer, thermometer, dropping funnel and condenser in a 500ml reaction vessel, add 150ml of toluene, 50g of 6-chloro-2-mercaptobenzoxazole and 1g of dimethylformamide, stir, and heat to 60°C, Trichloromethyl chloroformate was added dropwise, and after the addition, the temperature was raised to 80° C. to react for 3 hours, and the product was cooled to obtain 152 g with a content of 30.6% and a yield of 91.8%.

[0027] Example 3: Set up a stirrer, thermometer, dropping funnel and condenser in a 500ml reaction vessel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com