Single-sheet plastic bottle cap

A bottle cap and plastic technology, applied in the field of improvement of bottle cap structure, can solve problems such as excessive fluctuation of opening torque, large opening torque, increased contact resistance, etc., achieve improved sealing safety, increase top sealing structure, and open torque stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

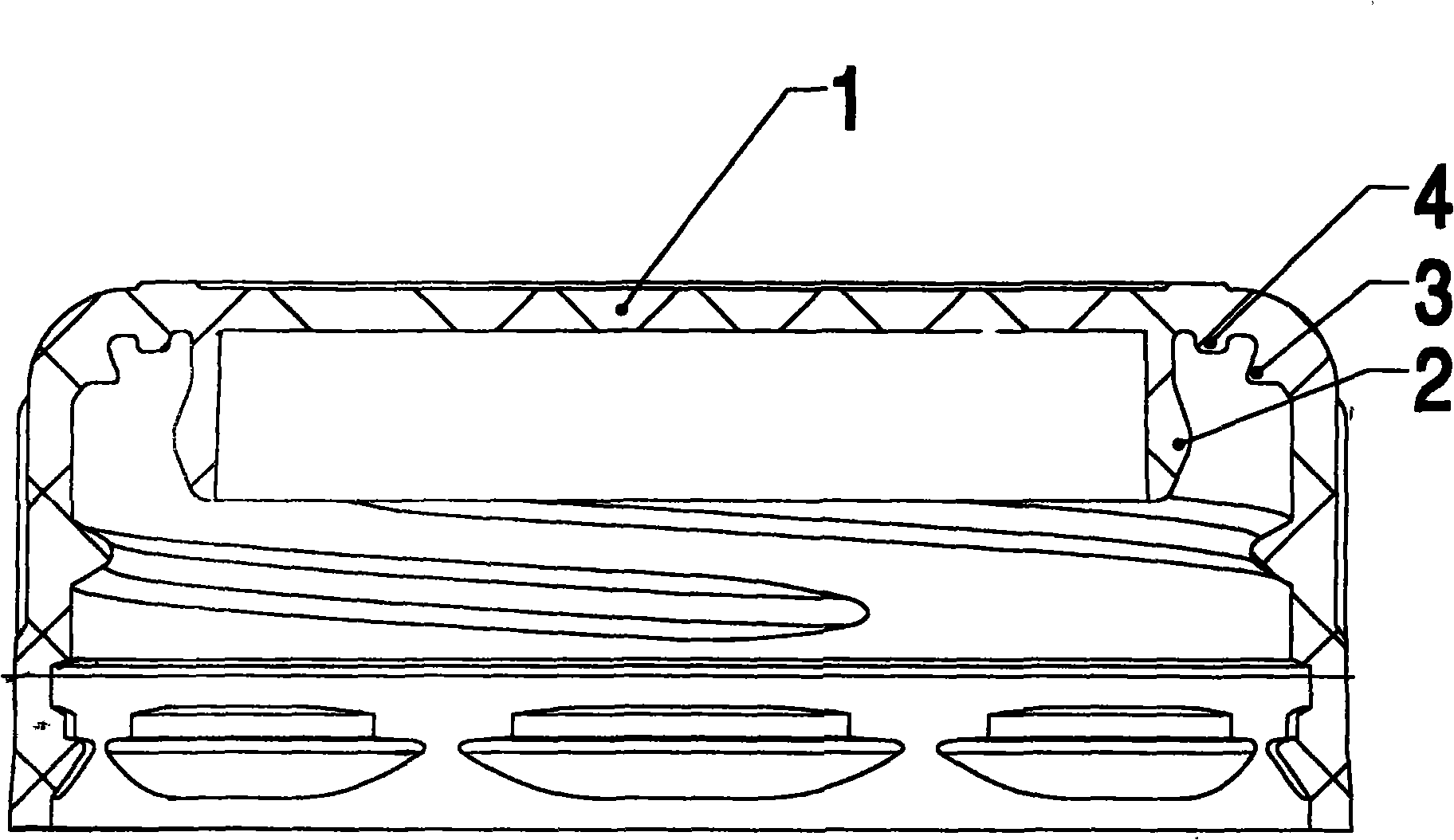

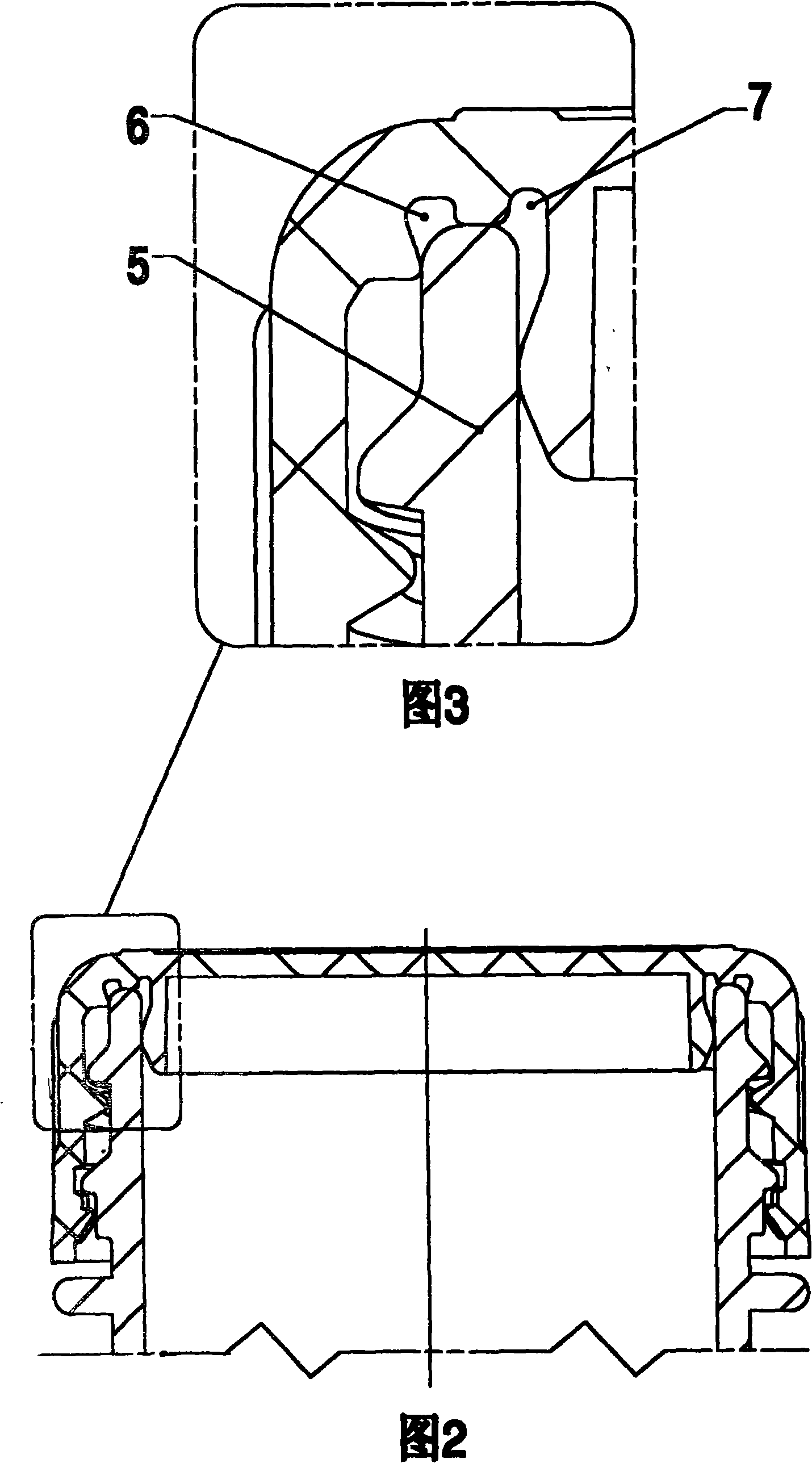

[0013] See attached figure 1 ~3.

[0014] A single-piece plastic bottle cap, the inner top surface of the bottle cap 1 has a ring-shaped inner plug 2, the outer surface of the ring-shaped inner plug is arc-shaped, and the largest diameter of the arc is larger than the inner diameter of the matching bottle mouth. The end of the ring-shaped inner plug 2 is rounded, so that the bottle cap can play a good guiding and transitional role when it enters the bottle mouth.

[0015] The outer ring of the inner top surface of the bottle cap 1 is provided with a ring-shaped top seal 4; .

[0016] The outer ring of the ring top seal 4 of the bottle cap 1 is provided with an outer seal 3 protruding from the side wall. The shape of the outer seal 3 is a barb shape, and the end is arc-shaped, so that the bottle cap can enter the bottle smoothly. mouth; during use, the outer sealing ring 3 cooperates with the outer wall of the bottleneck 5, and the inner diameter of the outer sealing ring 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com