Reversing device for fracturing operation

A reversing device and a technology in operation, which are applied to the valve device of wellbore/well, valve operation/release device, valve device, etc., can solve the problems of large structure and complicated operation process of the diverter device, and save installation and cost. Repair time, optimize the overall structure, reduce the effect of fluid leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

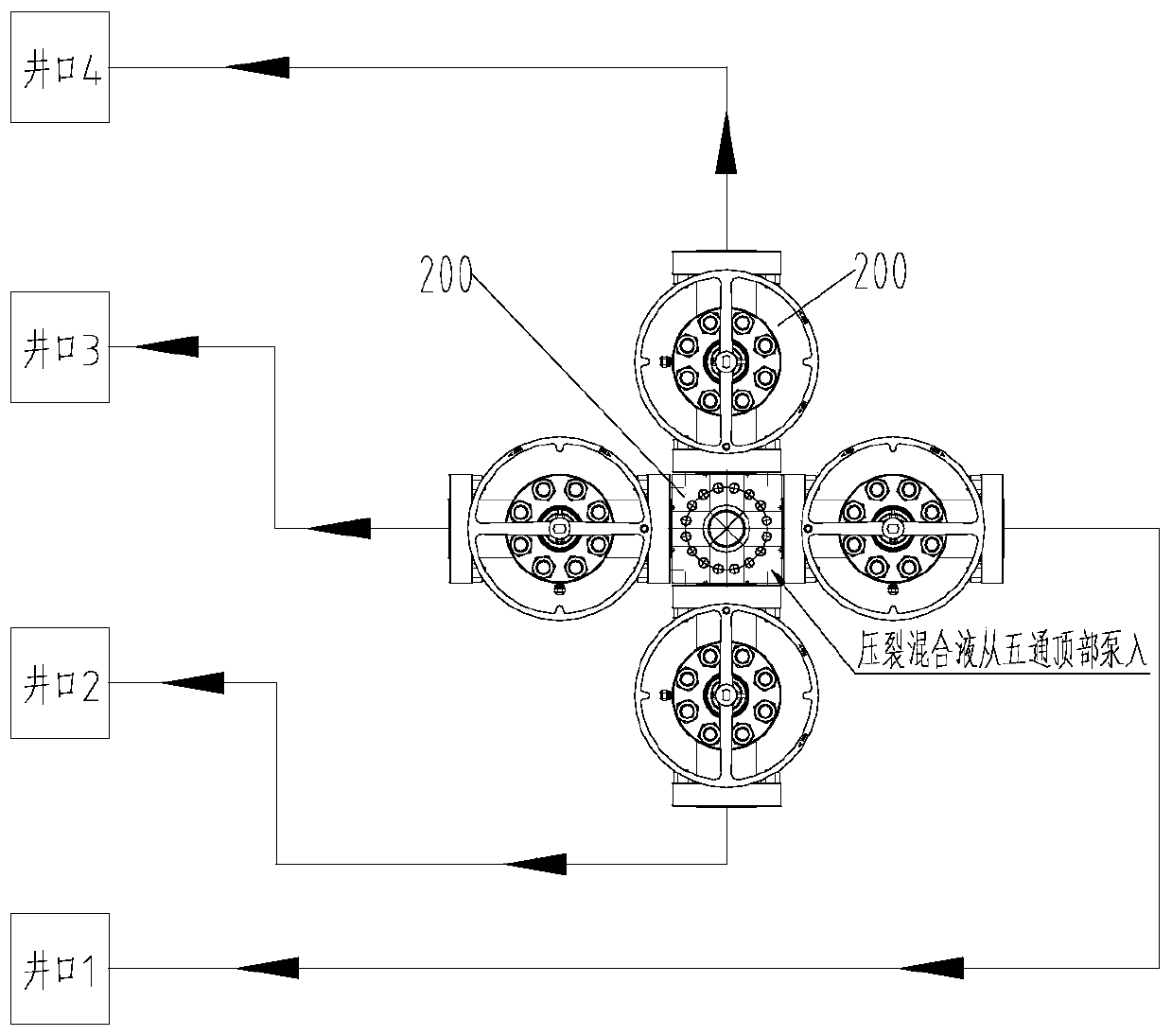

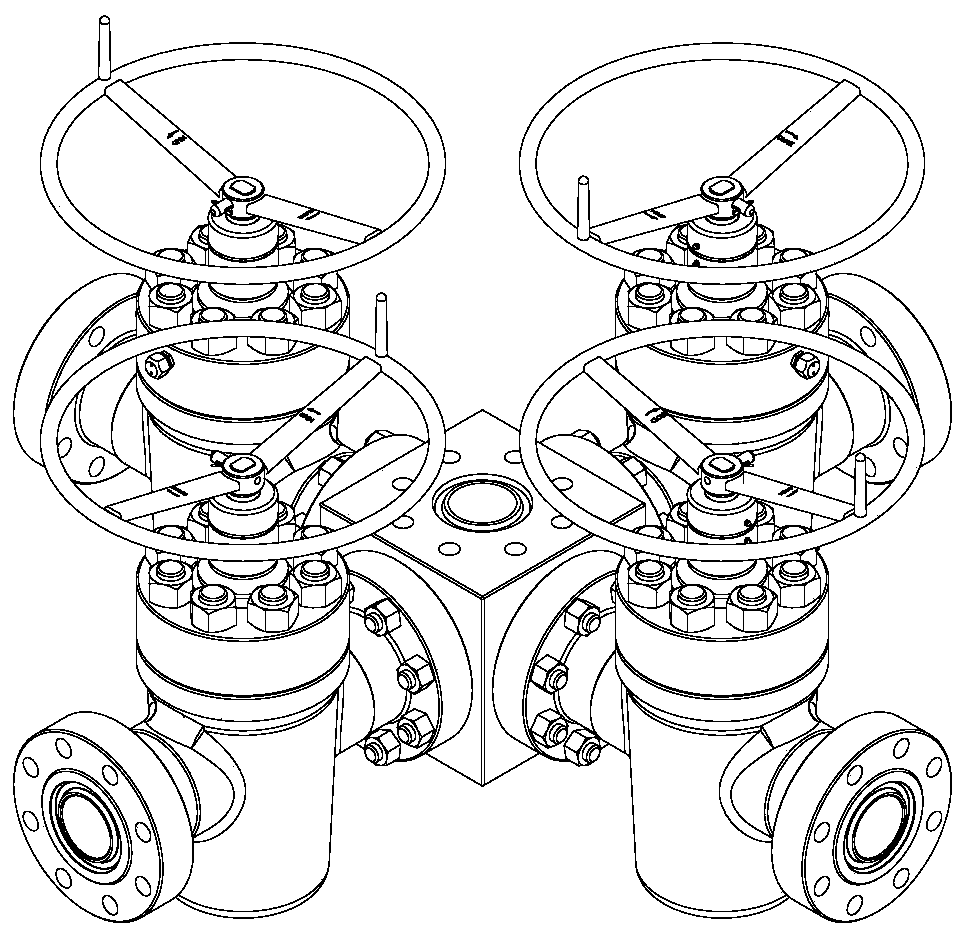

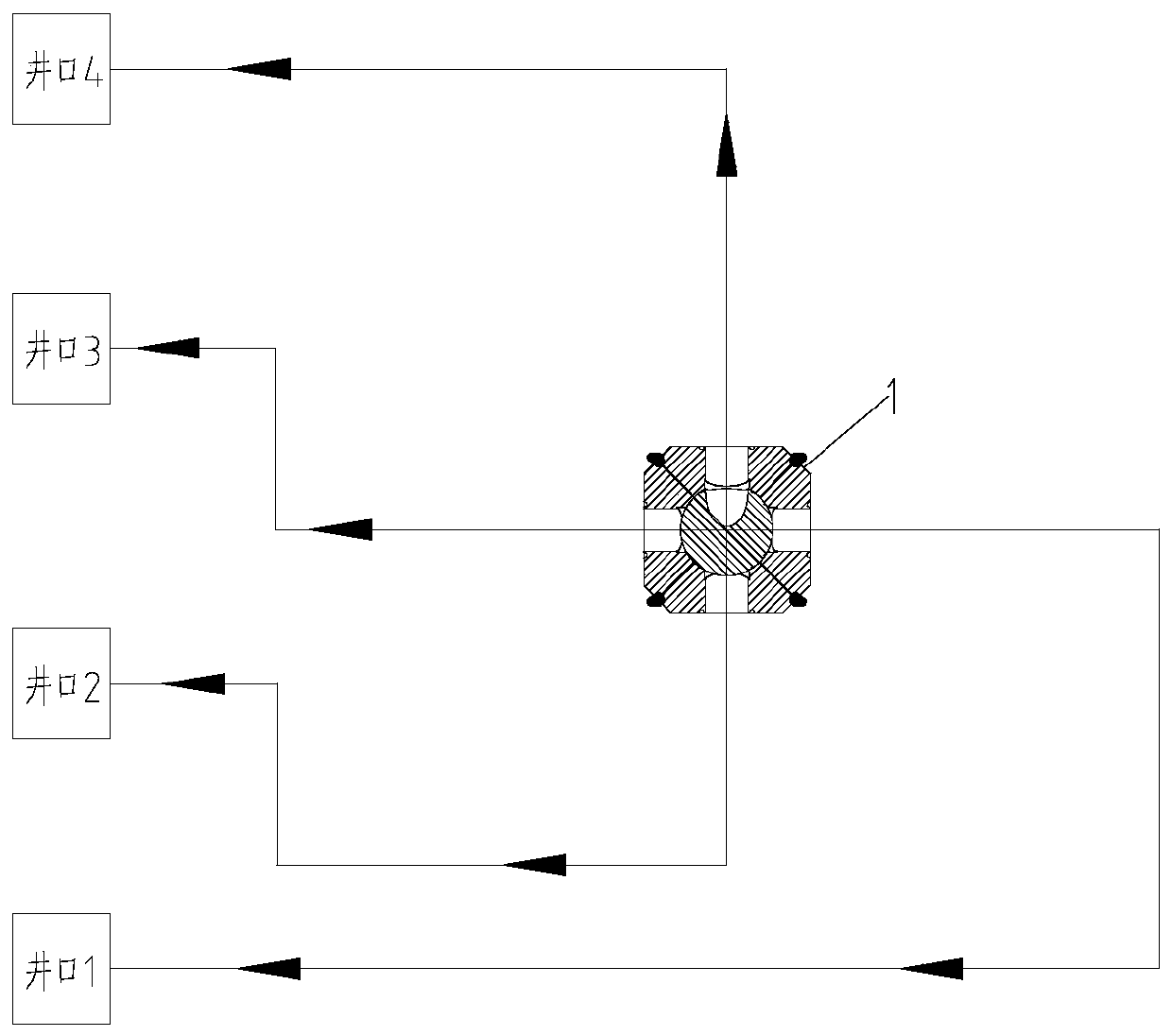

[0033] combine Figure 1 to Figure 8 A reversing device used in fracturing operations shown, in this embodiment, includes a body 1, a cock 2, a valve stem 3, a piston 4 and a first handle 5, and the cock 2 is assembled in the cavity of the body 1 , and its top is provided with a fracturing mixture inlet 6, and its side is provided with a first fracturing mixture outlet 9 communicating with the fracturing mixture inlet 6, and the side of the body 1 is provided with at least two groups of The second fracturing mixed fluid outlet 7 that is in rotational communication with the first fracturing mixed fluid outlet 9, the piston 4 is sealingly connected to the bottom end of the body 1, and its internal thread is connected to the valve stem 3, and the valve stem 3 extends into the body 1 One end is threadedly connected with the bottom end of the cock 2 , and the end protruding from the main body 1 is fixed with a first handle 5 .

[0034] There are four sets of second fracturing mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com