Microbubble swirl separation method and divice

A micro-bubble and fractionation technology, applied in flotation, solid separation, wet separation, etc., can solve problems such as difficult to find clogging, small nozzle diameter, increase the amount of foaming agent, etc., to achieve equipment simplification and processing capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

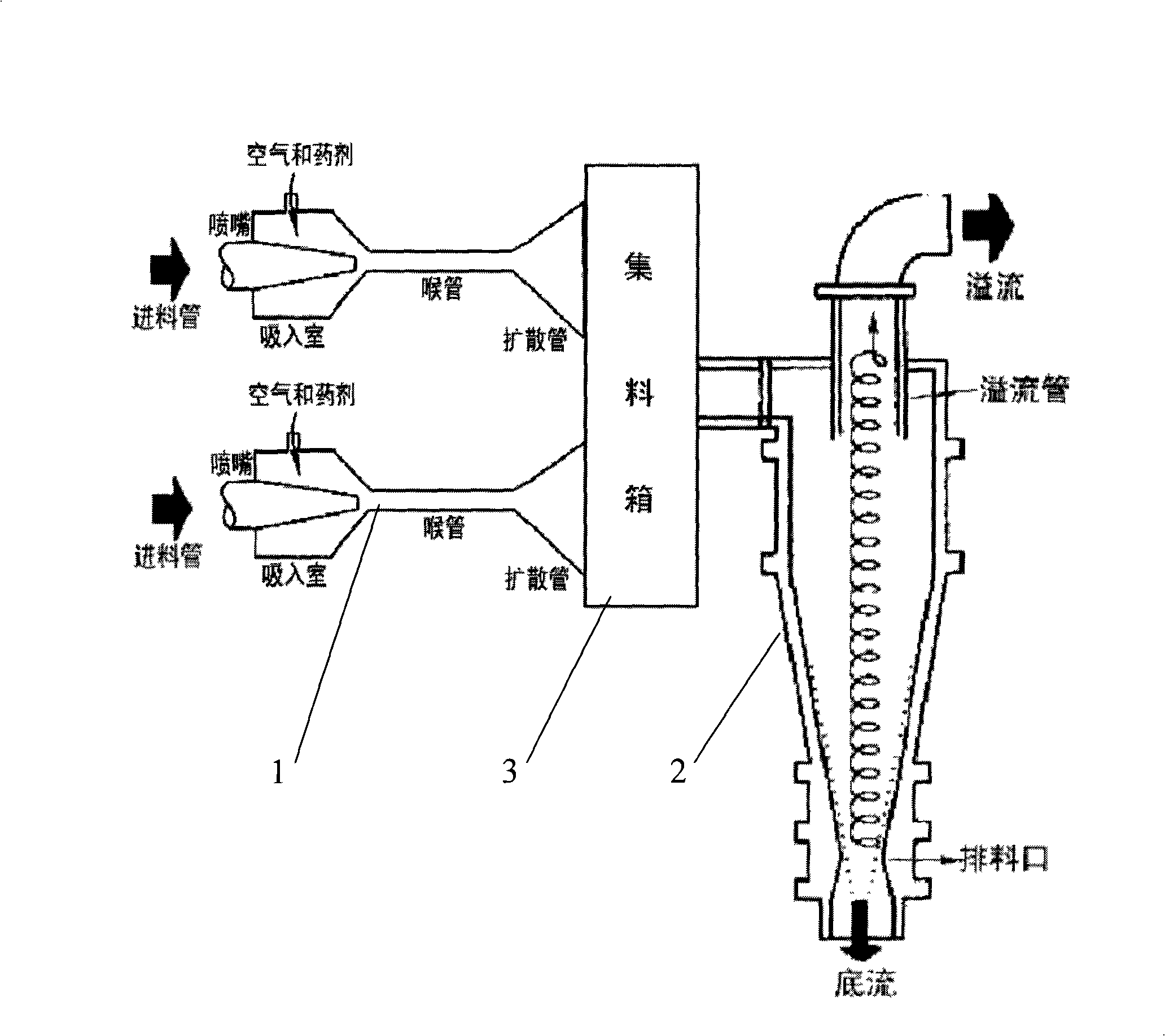

[0027] Such as figure 2 As shown, the equipment consists of several jet-type bubble generators 1 and coal slime dense-medium cyclones 2, and the jet-type bubble generators 1 and coal slime dense-medium cyclones 2 are connected by a collection box 3. Both the jet-type bubble generator 1 and the slime dense medium cyclone 2 are commercially available products. As a common separation and classification equipment, the cyclone is used for centrifugal sedimentation.

[0028] In order to improve the processing capacity of the cyclone, or to match the flow rate of the bubble generator with the cyclone, it is necessary to select several bubble generators in parallel according to the flow rate of the cyclone and connect them to the cyclone through the collecting box 3.

[0029] The working process is: the circulating slurry is pressurized to 0.25-0.3mpa by the slurry pump, and is sprayed out from the nozzle at high speed. Under the action of suction, the suction chamber forms a negati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com