Catalyst distillation column internals for high effective mass transfer

A technology for catalytic distillation towers and tower internals, applied in distillation separation, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as gas short circuit, low reaction efficiency, difficult coupling of reaction and separation, etc., and achieve control of residence time , to avoid the effect of overreaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

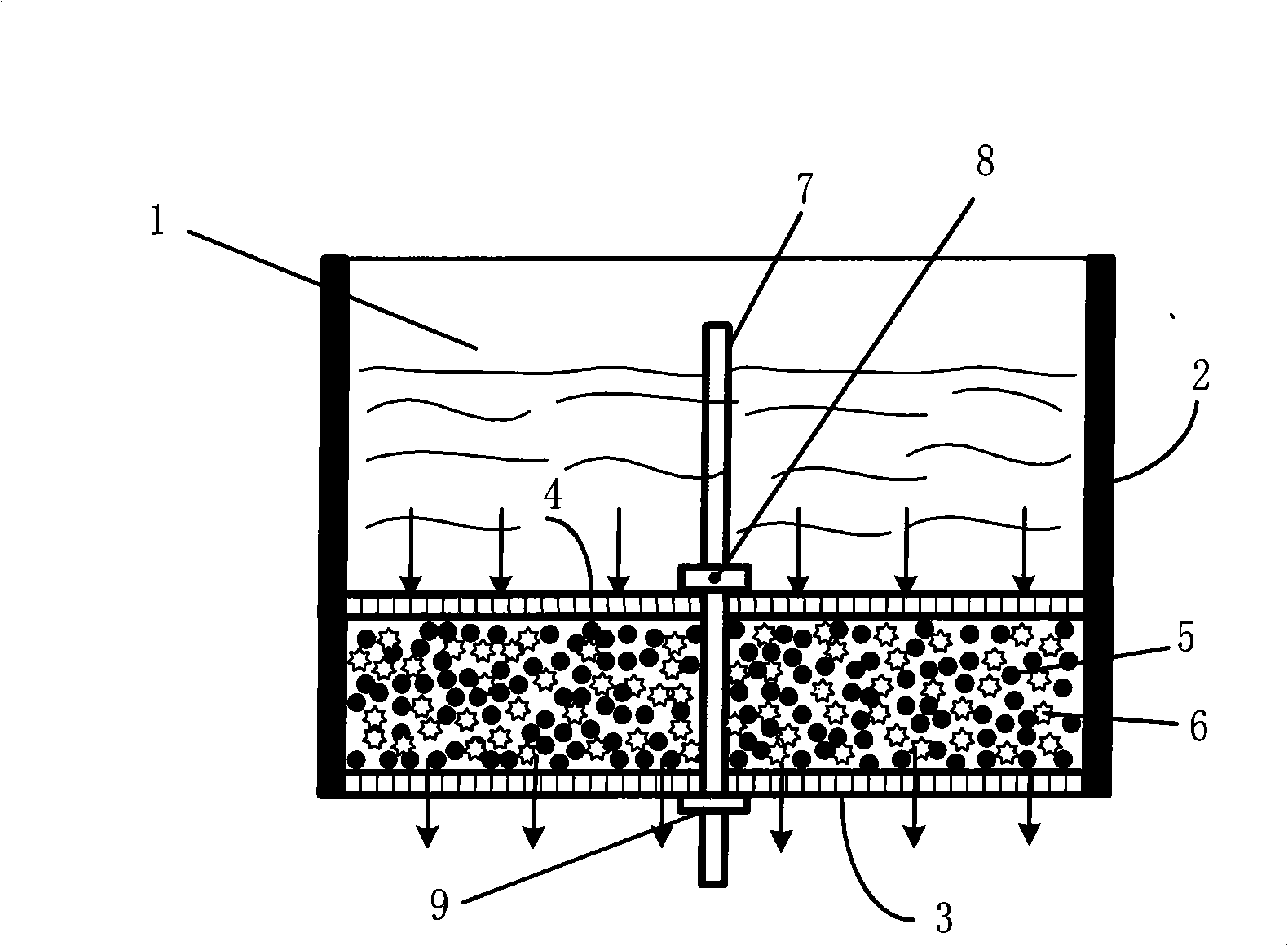

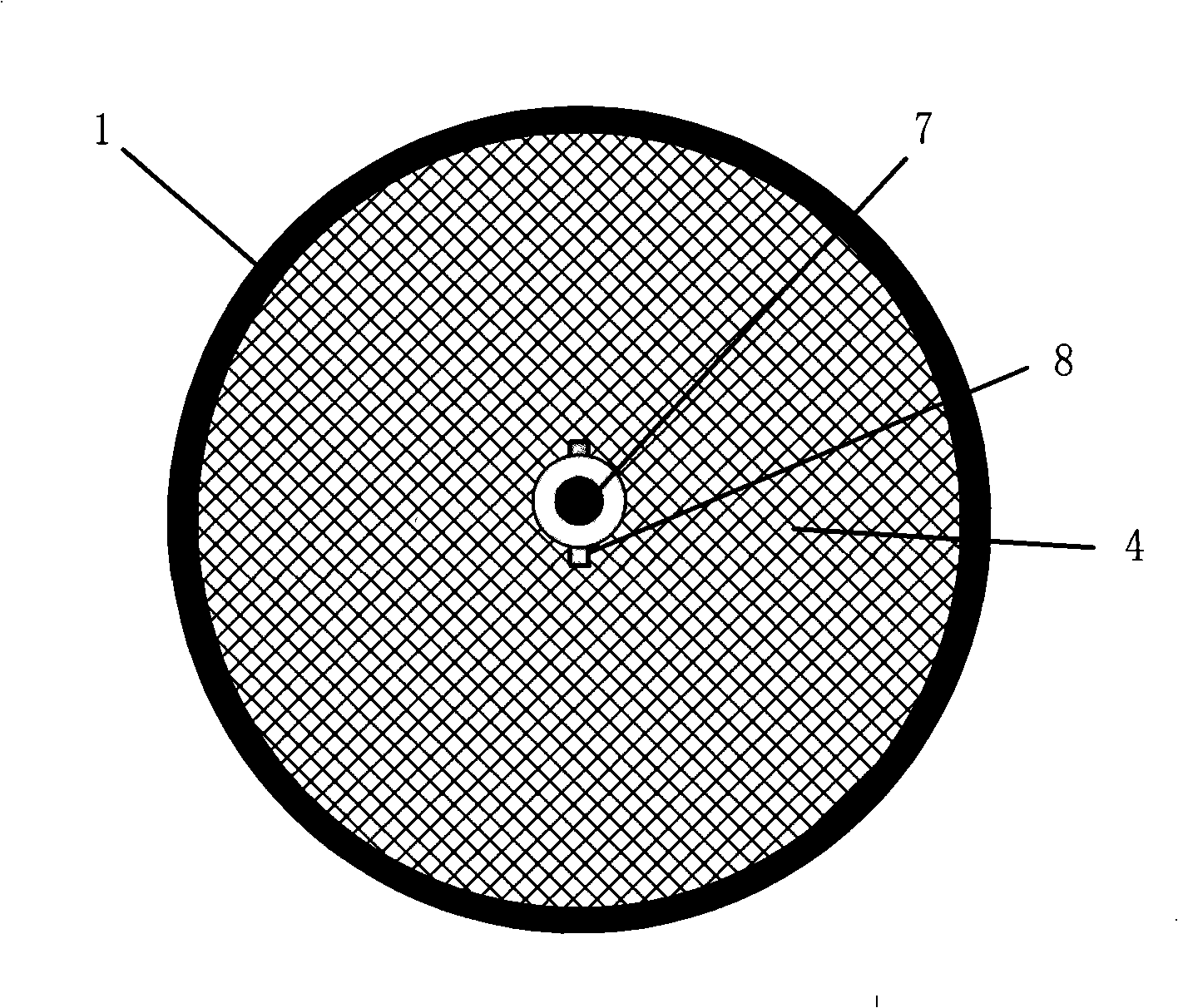

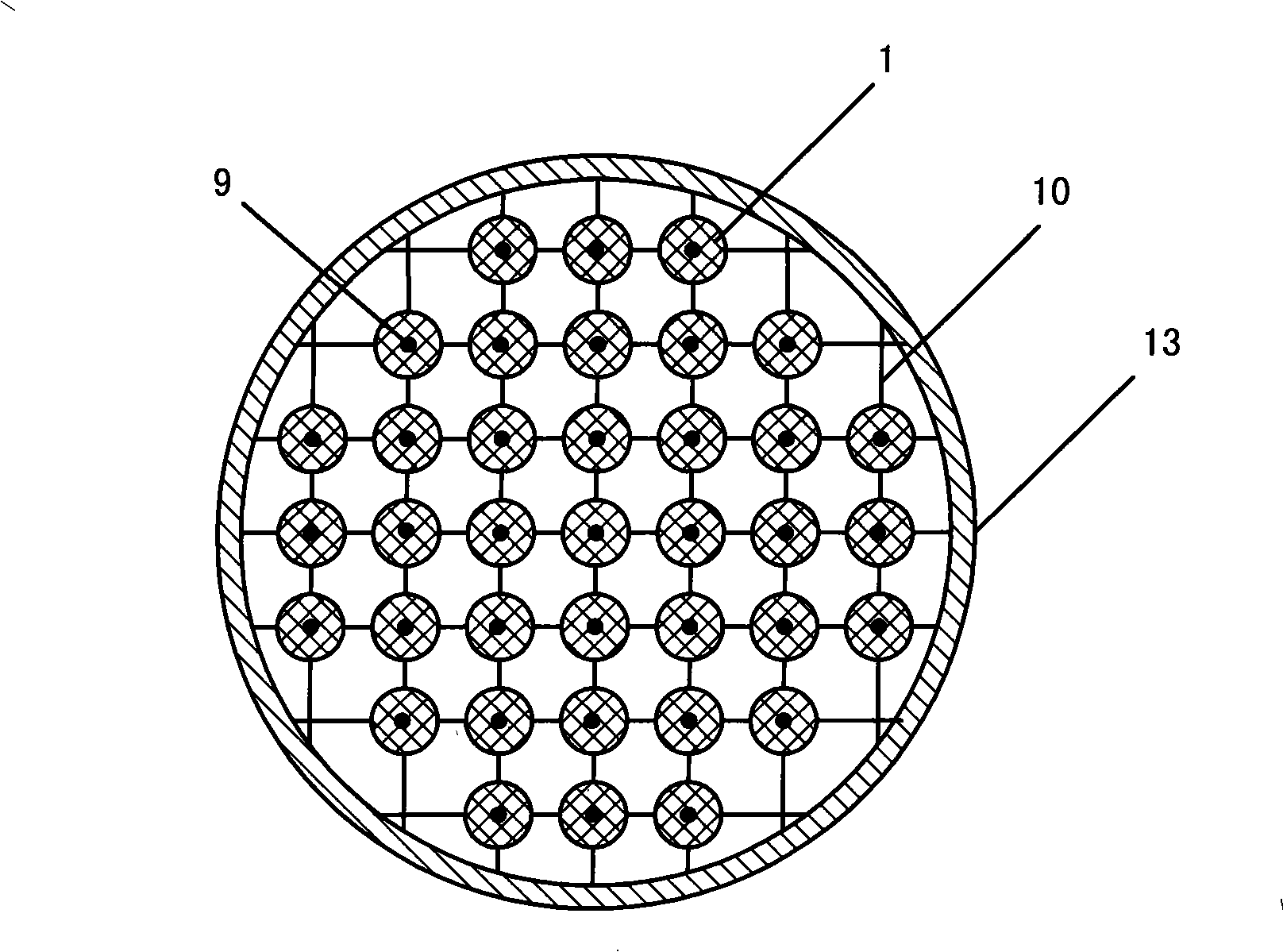

[0030] The catalytic distillation column internals 1 with the efficient mass transfer of circular cross-section are used for the catalytic distillation distillation unit of synthesizing methyl tert-butyl ether (MTBE), the longitudinal section structure of the column internals is as shown in Figure 1, and in the column The cross-section of the part is shown in Figure 2, and the tower internals are fixed at each cross point of the grid support 10 by nuts 9. The arrangement is as shown in Figure 3, and the adjacent upper and lower floors of the tower internals are arranged in a staggered manner. The grid support is fixed on the catalytic distillation tower wall 13, and the total cross-sectional area of the catalytic distillation tower internals on each layer of support is 70% of the catalytic distillation tower cross-sectional area, and stainless steel wire mesh structured packing is arranged below every two layers of tower internals 11. Its height is 20mm. As shown in Figure 5,...

Embodiment 2

[0032] The catalytic distillation column internals 1 of efficient mass transfer with rectangular cross-section is used for the catalytic distillation unit of synthetic ethyl tert-butyl ether (ETBE), the vertical section structure of column internals is as shown in Figure 1, each column At least two parts are fixed on the grid support 10 with nuts 9, and its arrangement is as shown in Figure 4. The total cross-sectional area of the catalytic distillation tower internals on each layer of support is 90% of the catalytic distillation tower cross-sectional area. The grid support is fixed on the catalytic distillation tower wall 13, the upper and lower tower internals are coaxially aligned, and the stainless steel wire mesh structured packing 11 is arranged between the upper and lower tower internals, and its height is 200mm. A liquid distributor 12 is arranged above, as shown in Figure 5, the height of the side wall 2 of the tower internals is 200mm, the opening ratio of the lower...

Embodiment 3

[0034] The catalytic distillation column internals 1 with the efficient mass transfer of rectangular cross section are used for the catalytic distillation unit of synthesizing methyl tert-butyl ether (MTBE), the vertical section structure of column internals is as shown in Figure 1, each column At least two parts are fixed on the grid support 10 with nuts 9, and its arrangement is as shown in Figure 4. The total cross-sectional area of the catalytic distillation tower internals on each layer of support is 95% of the catalytic distillation tower cross-sectional area. The lattice support is fixed on the catalytic distillation tower wall 13, and each adjacent upper and lower two-layer tower internals are arranged in a staggered manner, and a liquid distributor 12 is arranged above each layer of tower internals, such as Figure 7As shown, the height of the side wall 2 of the tower internals is 500mm, the opening ratio of the lower bottom 3 and the upper bottom 4 is 20%, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com